A Modeling Method of Compressor Blade Suction Surface Based on Streamline Field Theory

A modeling method and suction surface technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to obtain well-solved curves, high complexity, complex differential equations, etc. More scientific, reduced number of parameters, high smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

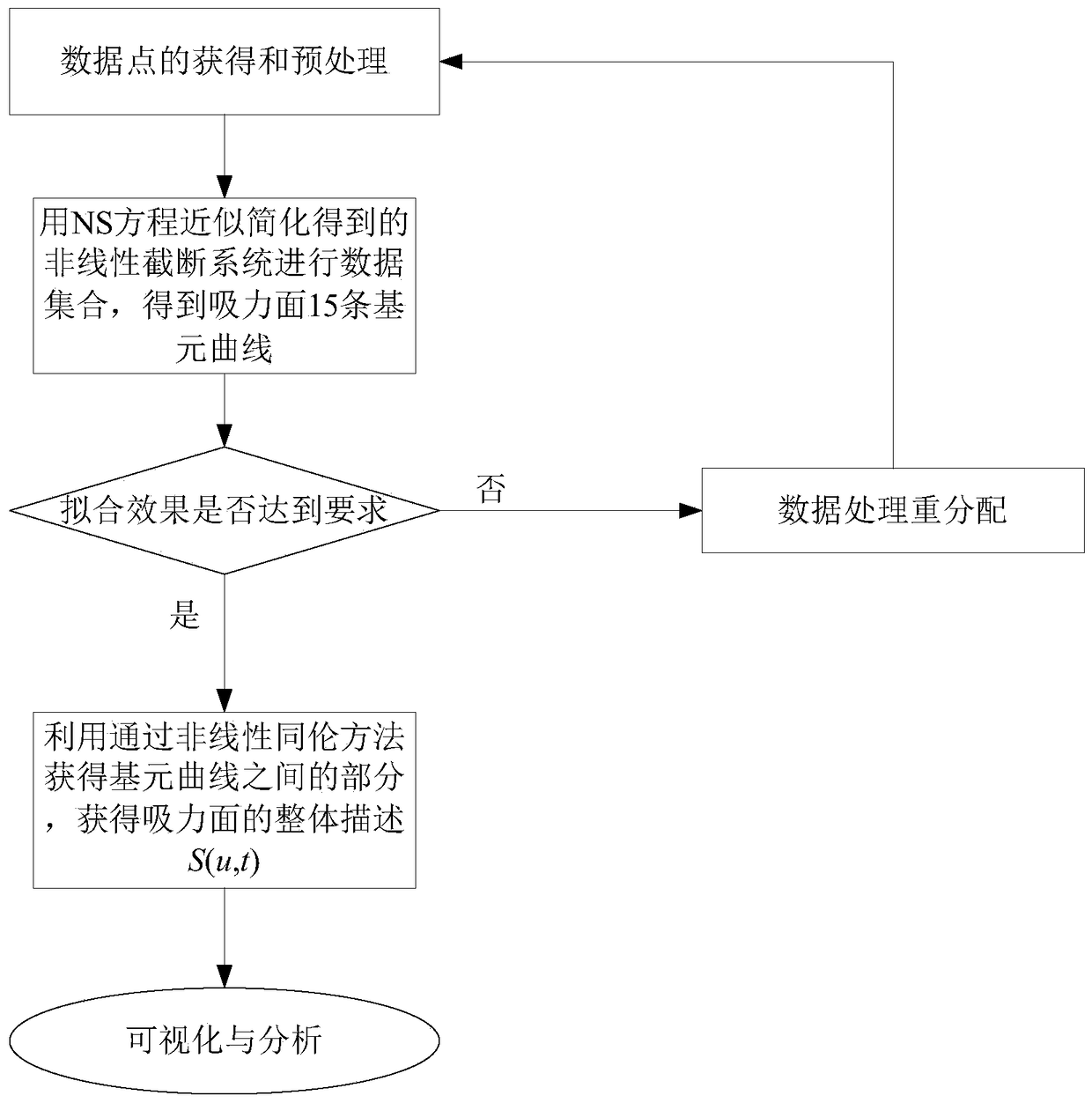

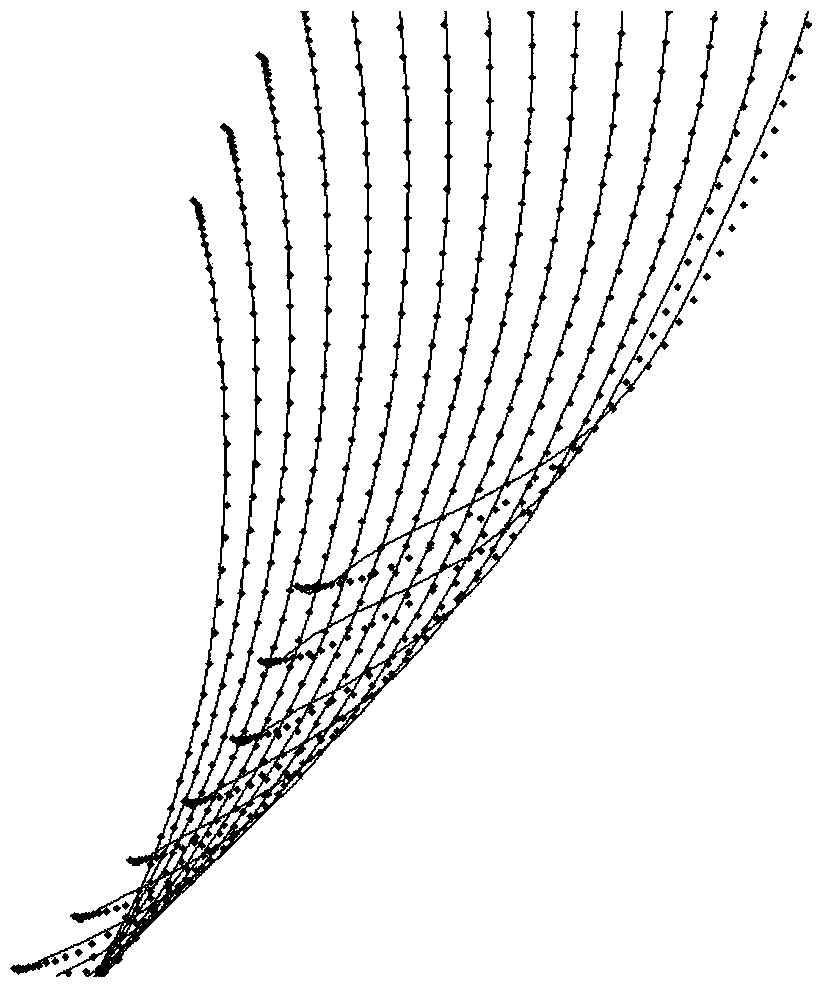

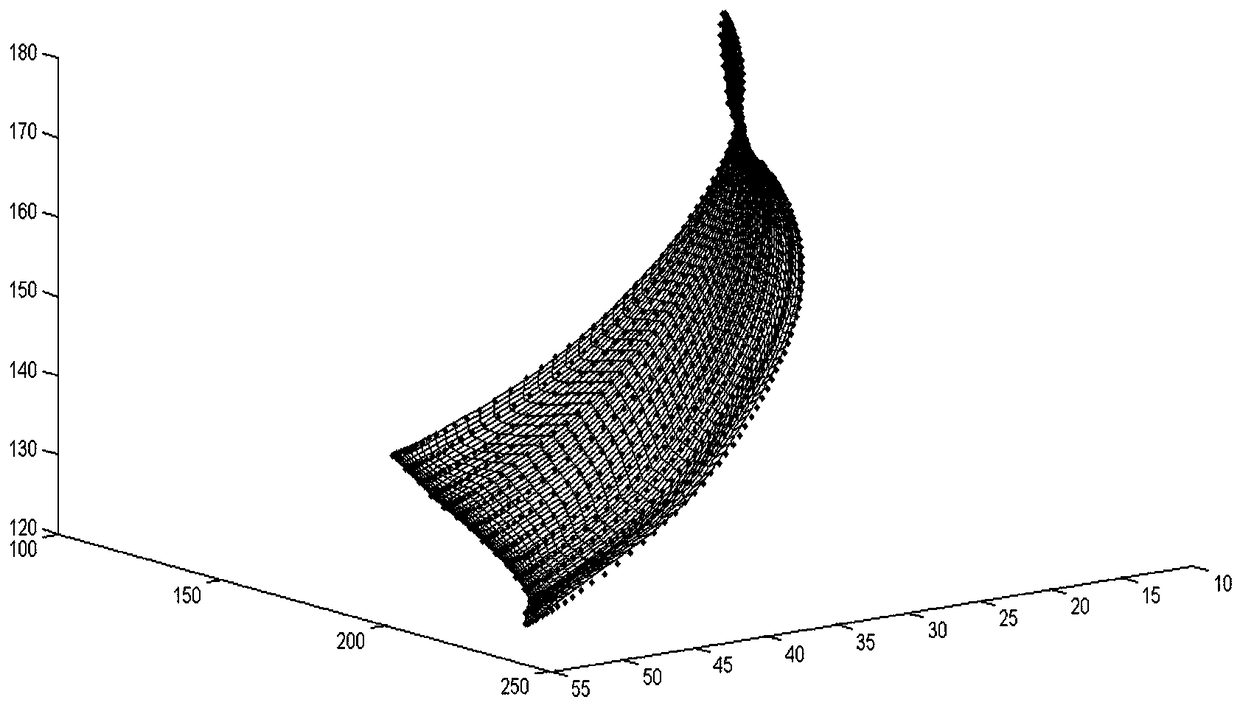

[0035] A method for modeling the suction surface of a compressor blade based on the streamline field theory provided by the present invention, such as figure 1 shown, including the following steps:

[0036] Step 1: Acquisition and preprocessing of data points.

[0037] The invention processes the data obtained from the preliminary design of the compressor blades, obtains the suction surface data set of the compressor blades and imports them.

[0038] The compressor blade is a rotor67 rotor, which is a compressor rotor blade that has been fully tested abroad, the geometry is disclosed, and it is used to provide various research institutions for research. Detailed data, geometric characterization and aerodynamic performance of compressor blades are provided in the following literature.

[0039] Strazisar A J, et al.Laser Anemometer Measurements in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com