Electric cooker with bilayer outer pot

A technology for electric rice cookers and outer pots, applied to pressure cookers, the structure of cooking utensils, cooking utensils, etc., can solve the problems of long time required, high energy consumption, etc., and achieve good taste and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

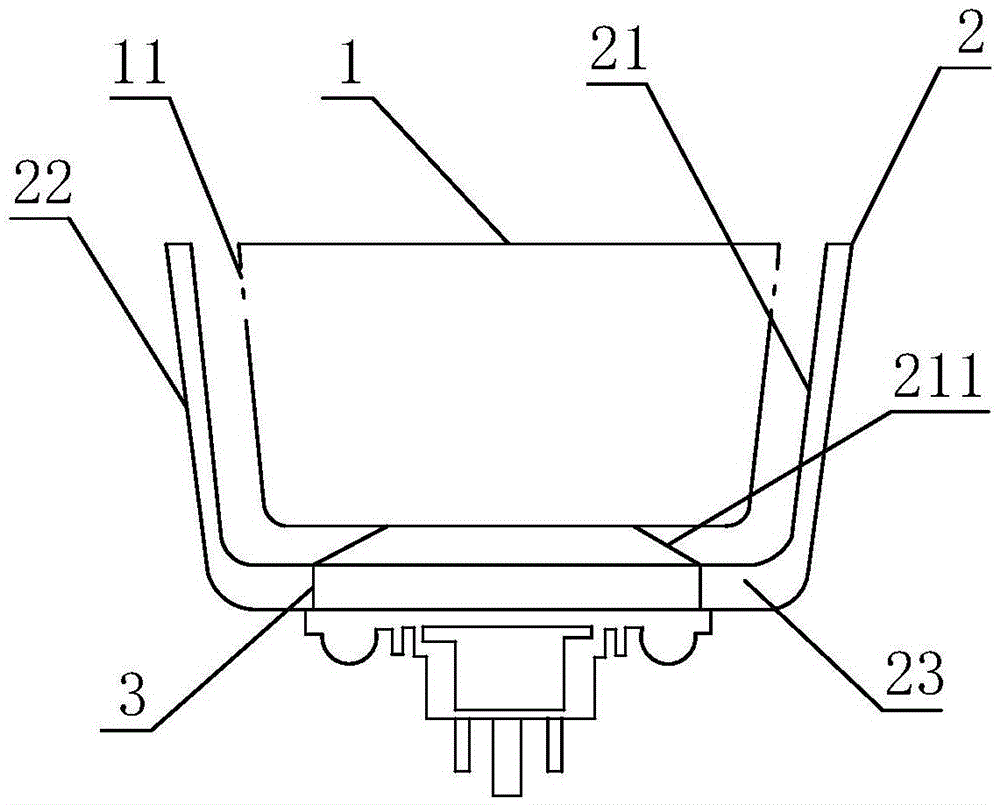

[0028] Such as figure 1 As shown, Embodiment 1 of the present invention relates to an electric rice cooker with a double-layer outer pot, comprising: an inner pot 1 and an outer pot 2; the outer pot 2 is a double-layer structure, including an inner pot 21 and an outer pot 22; the inner pot 21 The upper edge is connected with the upper edge of the outer container 22, and there is an interlayer 23 between the inner container 21 and the outer container 22; the interlayer 23 is provided with a heat pipe 3; the inner pot 1 is placed in the inner container 21, and the inner container 21 is used to hold water; the upper part of the pot wall of the inner pot 1 is provided with a plurality of ventilation holes 11, and the ventilation holes 11 are arranged above the water surface.

[0029] When in use, put an appropriate amount of water into the inner pot 21, put the cleaned food into the inner pot 1, put the inner pot 1 into the inner pot 21, heat the water in the inner pot 21 through ...

Embodiment 2

[0041] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the bottom of the inner pot 1 is provided with a plurality of ventilation holes 11 .

[0042] A plurality of ventilation holes 11 are arranged on the bottom of the inner pot 1 . Ventilation holes 11 are added to the bottom of the inner pot 1 to allow the food to receive more steam, and increase the parts where the food receives steam, so that the food is heated more evenly and it is easier to cook the food.

Embodiment 3

[0044] Such as Figure 5 As shown, the difference between this embodiment and embodiments 1 and 2 is that: the upper edge of the inner pot 1 is provided with a flange 12, and the upper edge of the outer pot 2 supports the flange 12, so that the inner pot 1 is set in the inner pot 21. The inner pot 1 is supported on the outer pot 2 through the flange 12 to prevent the inner pot 1 from being unstable in the inner tank 21 due to the buoyancy of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com