Double-action progressive prestressed plate four-axis pulse electromagnetic shape adjustment and tonality device

A pulse electromagnetic and progressive technology, applied in the field of metal plastic forming equipment, can solve the problems of poor adaptability and flexibility, inability to provide prestress, low energy utilization rate, etc., to achieve versatility and adaptability, improve Space utilization rate, the effect of overcoming cumbersome clothing and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

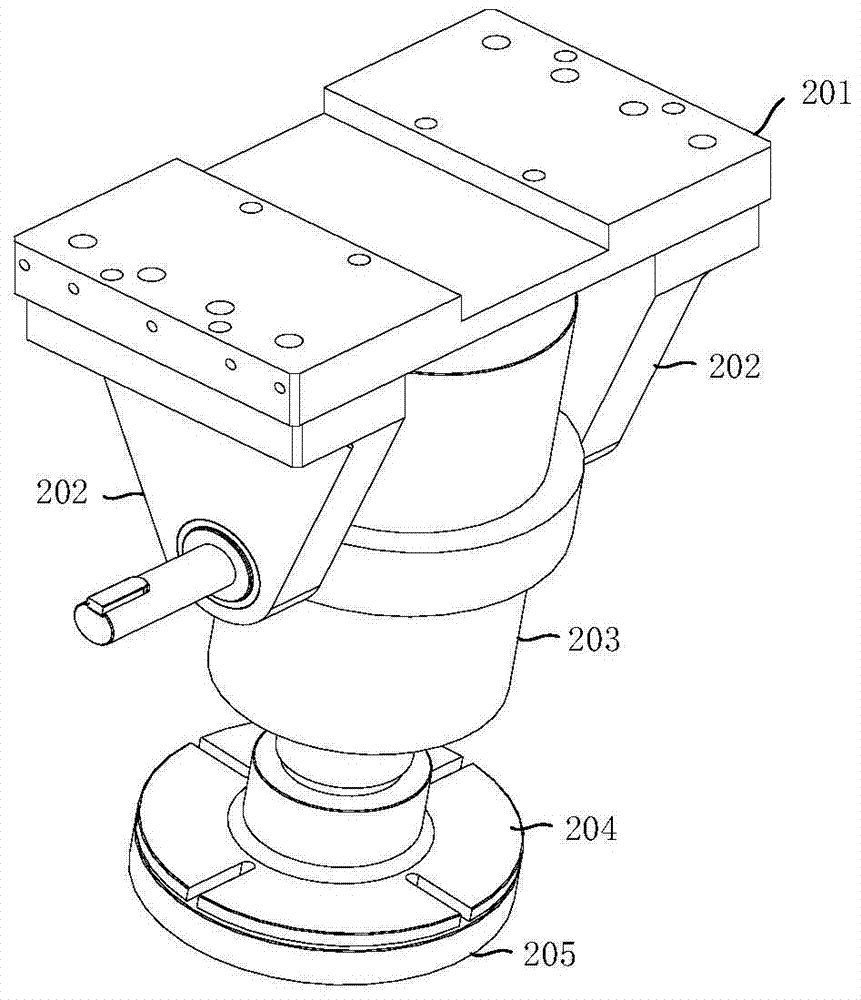

[0061] The dual-action progressive prestressed plate four-axis pulse electromagnetic shape adjustment and tonality device of the present invention is used to apply pulse electromagnetic force on the metal plate, adjust the stress and strain state inside the plate and the material structure, so as to change the shape and shape of the plate. performance purposes. Before using the pulse electromagnetic force to hit the plate, it is required to preload the plate by applying pre-stretching, pre-bending or both pre-stretching and pre-bending, so that the plate has different prestressed states.

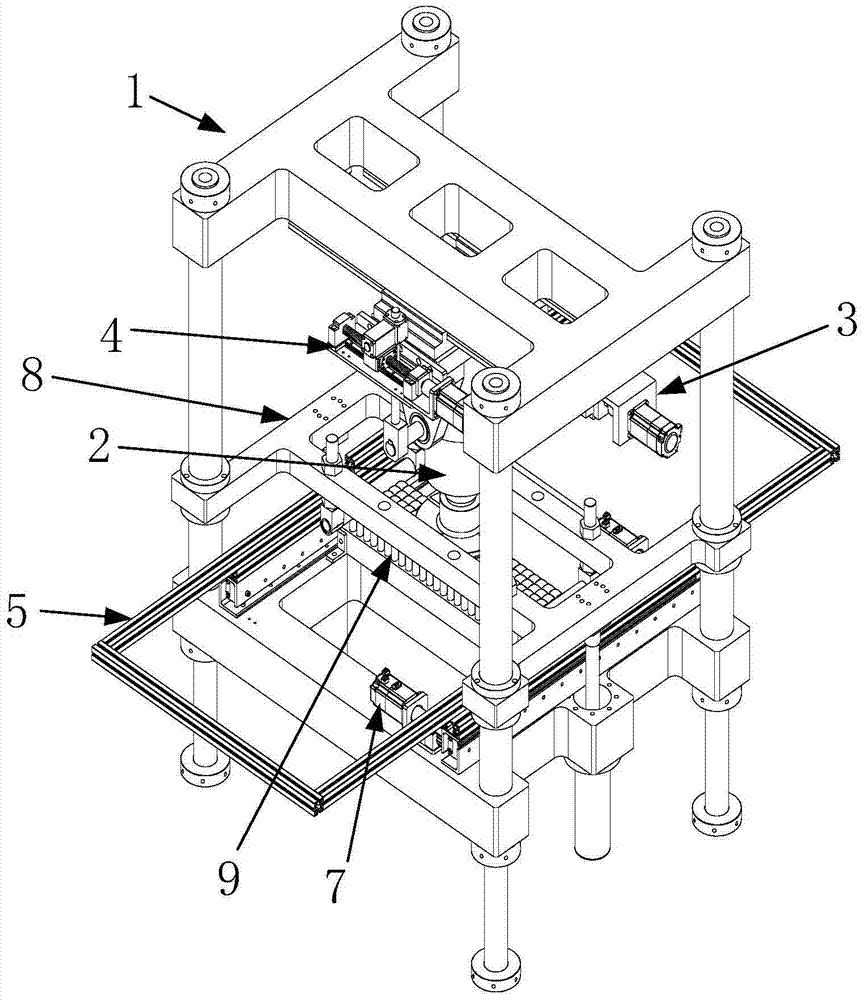

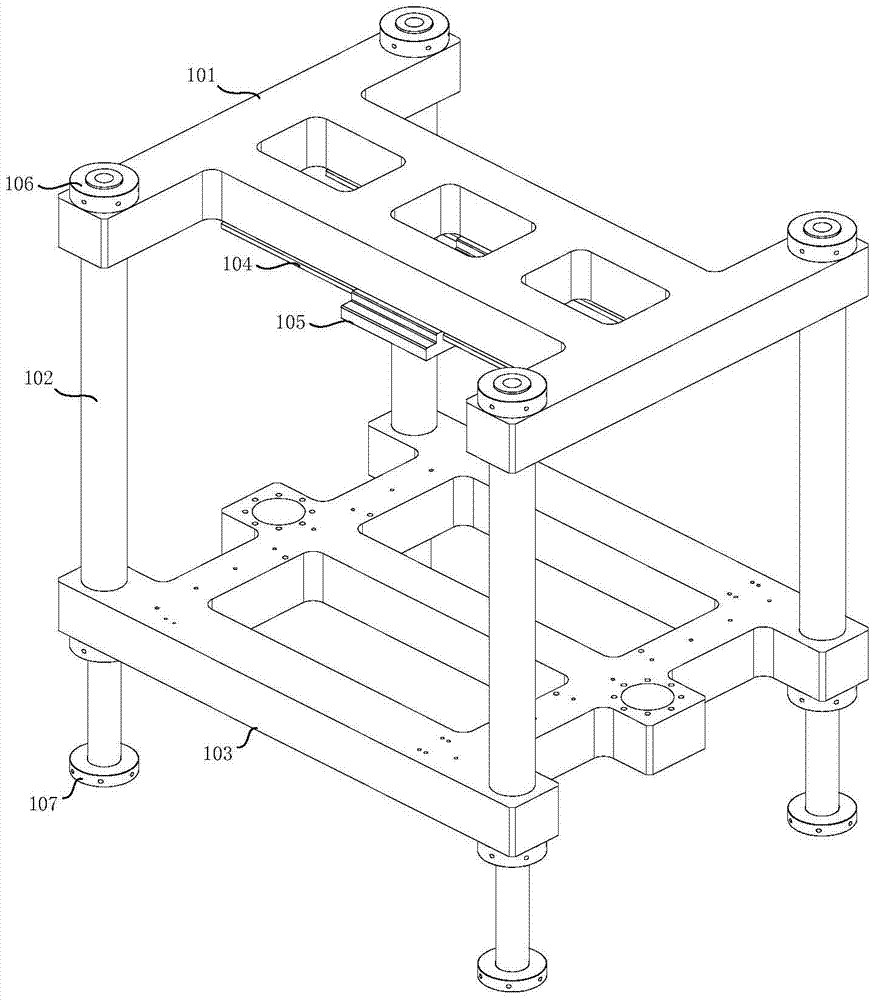

[0062] The double-action progressive prestressed plate four-axis pulse electromagnetic shape adjustment and tonality device of the present invention includes a main frame 1, a coil control hydraulic cylinder assembly 2, a hydraulic cylinder translation drive assembly 3, a hydraulic cylinder swing angle drive assembly 4, and a plate feed Frame assembly 5, plate chuck assembly 6, plate feed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com