Formative technology for three-cylinder bent axle

A molding process and crankshaft technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of difficult three-cylinder crankshaft overall horizontal parting, high casting waste rate, and shrinkage cavity of connecting rods, etc., to improve the universal rate , Reduction of scrap rate, faster cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

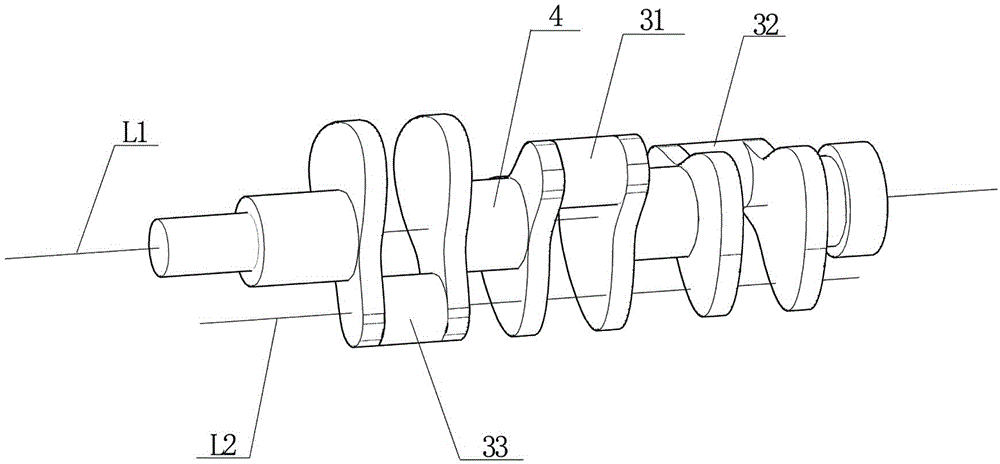

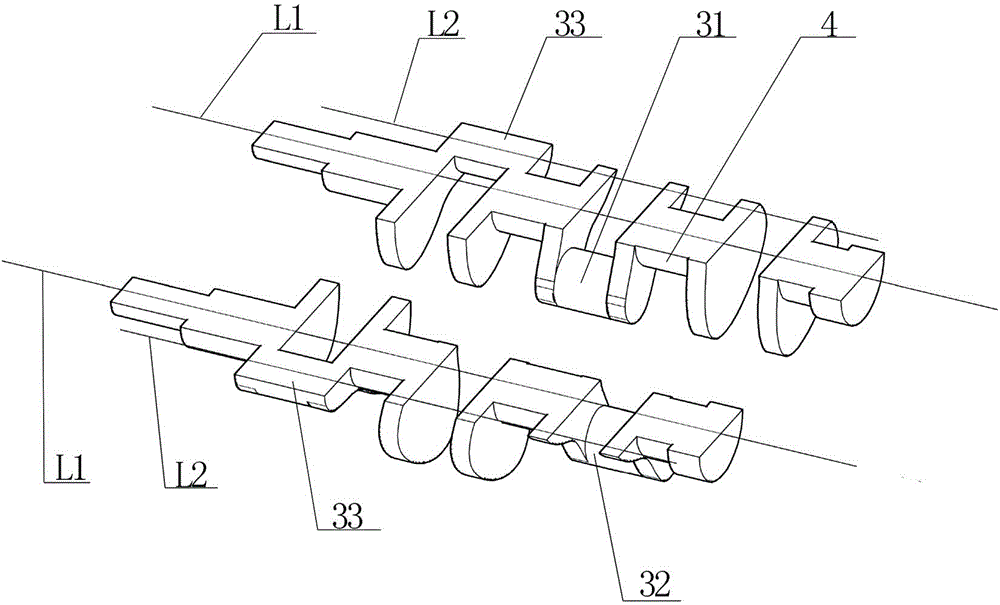

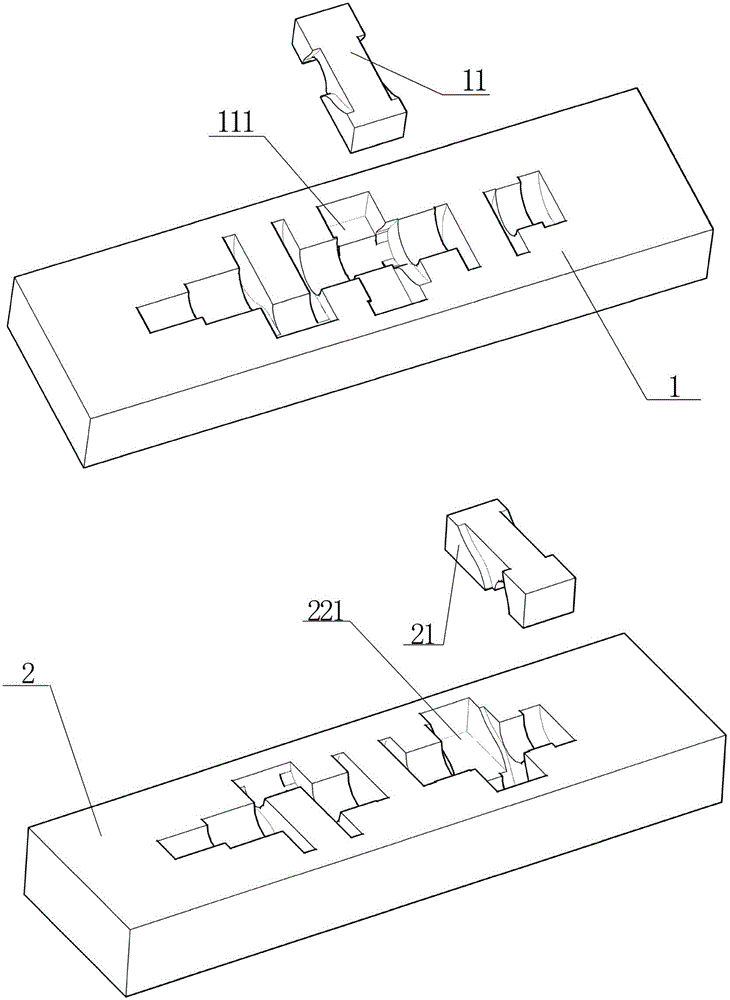

[0015] Such as Figure 1 to Figure 4 Shown: a molding process of a three-cylinder crankshaft: its special feature is that during its modeling design process, the crankshaft mold follows the first centerline L1 of the main journal 4 and the second centerline of the third connecting rod journal 333 The plane parting where L2 is located is divided into upper mold base 1 and lower mold base 2 according to the parting crankshaft mold, and the other two connecting rod journals distributed at an angle of 120 degrees are connecting rod journal 1 and connecting rod journal Two 32; the casting cavity of connecting rod journal one 31 is located on the upper mold base 1, and the casting cavity of connecting rod journal two 32 is located on the lower mold base 2. The upper mold base 1 is provided with a core-11, and the body of the lower mold base-1 is provided with a core groove-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com