Wire end fixing method and device of wire winding spool

A fixing method and I-shaped wheel technology are applied in the field of metal wire deep processing to achieve the effect of improving labor efficiency, reducing labor intensity and ingenious principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

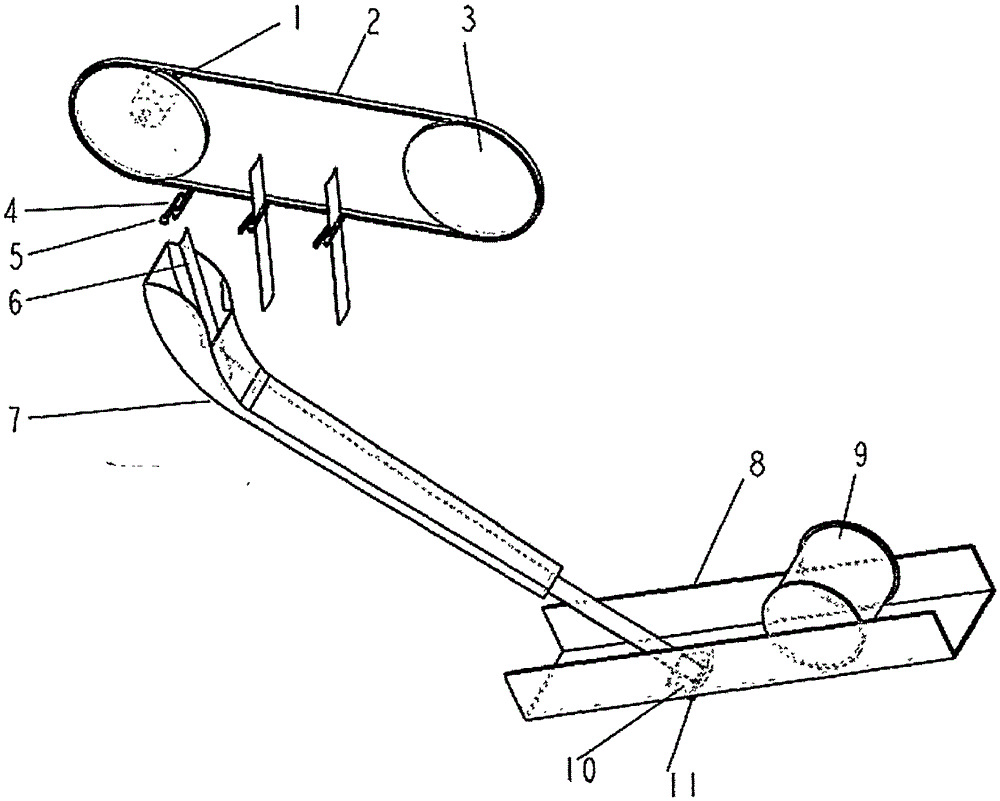

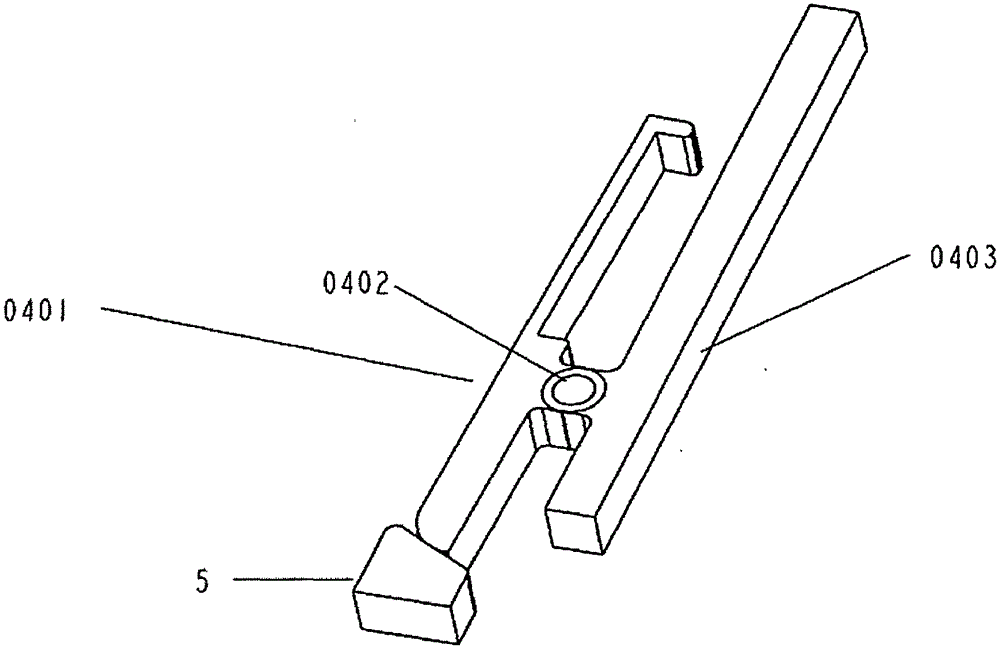

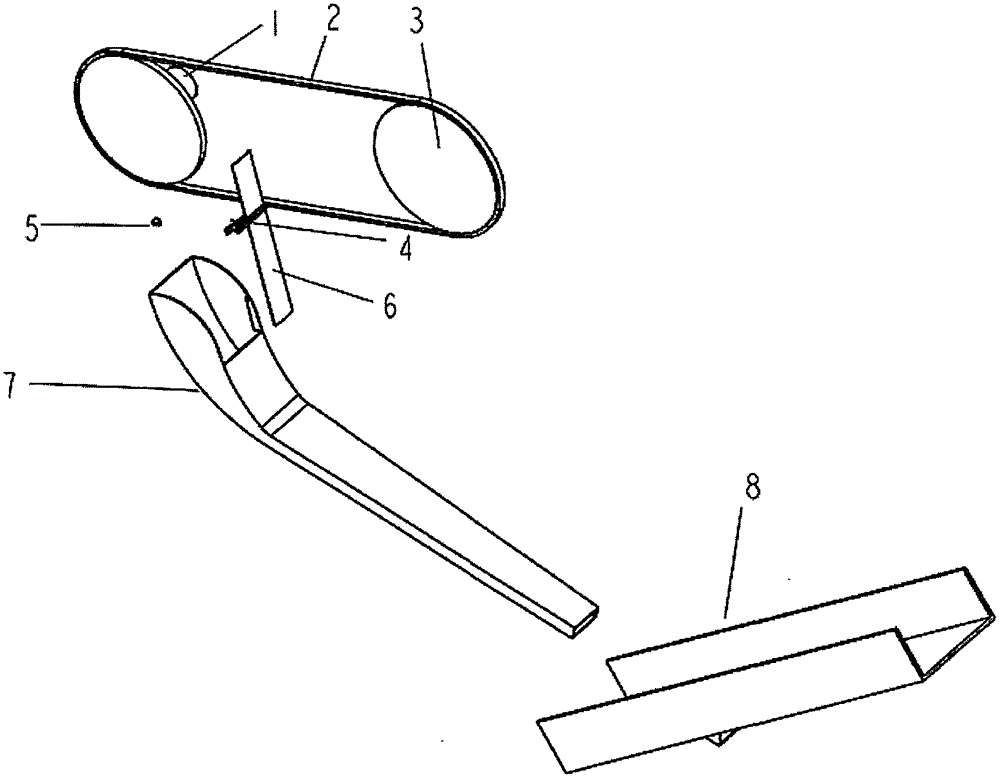

[0024] As shown in the accompanying drawings, the present invention includes two sprockets 3 driven by a stepping motor 1, a transmission chain 2, and several regularly arranged spring clips 4 fixed to one side of the transmission chain 2 with bolts, clamped in the spring clip 4 The self-rolling steel sheet 6 between the sheets is fixedly installed on the spring clip stopper 5 on the frame, and the moving spring clip 4 can touch the spring clip stopper 5; the fixed steel sheet slides under the spring clip stopper 5 Road 7, the I-shaped wheel slideway 8 with adjustable inclination angle and the center alignment device of the steel sheet slideway 7, said I-shaped wheel slideway 8 has a long hole, and a steel sheet blocking block 10 is installed below the long hole, and the steel sheet Shock-absorbing rubber pad 11 is arranged before the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com