Cable reel and self-propelled hoist conveying device using same

A self-propelled hoist and wire winder technology, applied in the field of wire winders, can solve the problems of large space occupation, difficult installation and maintenance, complex structure, etc., and achieve the effects of convenient installation and maintenance, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

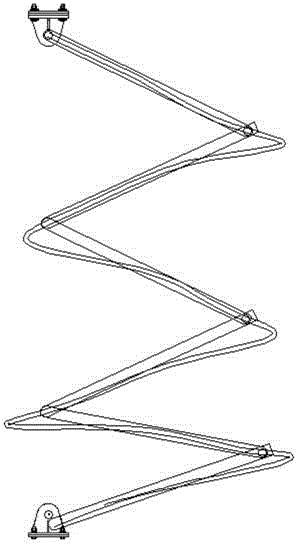

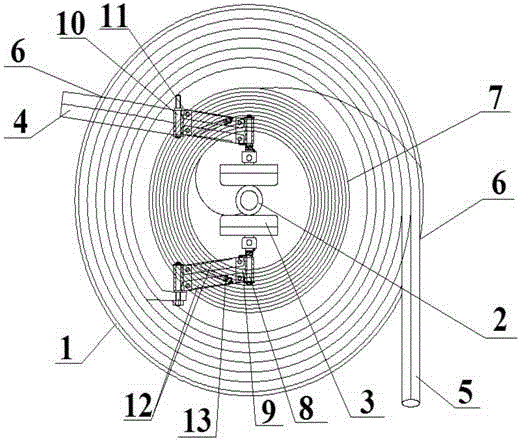

[0025] A cable winder such as figure 2 As shown, it includes a cable storage box 1, the two sides of the cable storage box 1 are respectively provided with cable outlets 6, the cable storage box 1 is provided with a rotatable conductive mandrel 2, and the shaft body of the mandrel 2 is symmetrically connected with two electric cables. The connecting piece 3, the two electric connecting pieces 3 are respectively connected with the first cable 4 and the second cable 5, wherein the two electric connecting pieces 3 are respectively connected with two first rotating shafts 8, and the first rotating shaft 8 is rotatably mounted on the first In the rotating shaft seat 9, one end of the first cable 4 and the second cable 5 is respectively connected with a second rotating shaft 10, and the second rotating shaft 10 is rotatably installed in the second rotating shaft seat 11, and the second rotating shaft seat rotatably connected with the first cable 4 11 is connected with the correspon...

Embodiment 2

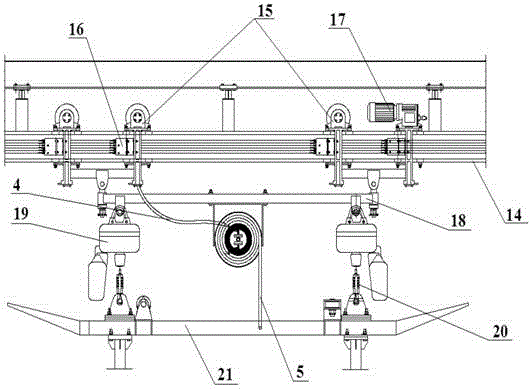

[0027] Self-propelled hoist conveyors using cable winders, e.g. figure 2 with image 3 As shown, the self-propelled gourd conveying track 14 is included, the self-propelled gourd conveying track 14 is provided with a traveling device 15, the traveling device 15 is connected with a control device 16 and a drive motor 17, and the lower end of the traveling device 15 is hung with an upper support beam 18, and the upper support beam Two electric hoists 19 are hoisted below 18, and the two electric hoists 19 are respectively connected to the lower support beam 21 through the sling 20, and the upper support beam 18 is fixedly connected to the cable storage box 1, and the two sides of the cable storage box 1 are respectively provided with cable outlets 6 A rotatable conductive mandrel 2 is arranged in the cable containing box 1, and two electric connecting pieces 3 are symmetrically connected to the shaft body of the mandrel 2, and the two electric connecting pieces 3 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com