Water-dilutable sol-gel composition

A gel composition and composition technology, applied in the direction of dissolution, chemical/physical processes, and devices for coating liquids on the surface, can solve the problems of limited water dilutability, etc., and achieve excellent corrosion protection properties, good hardness and Excellent scratch resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

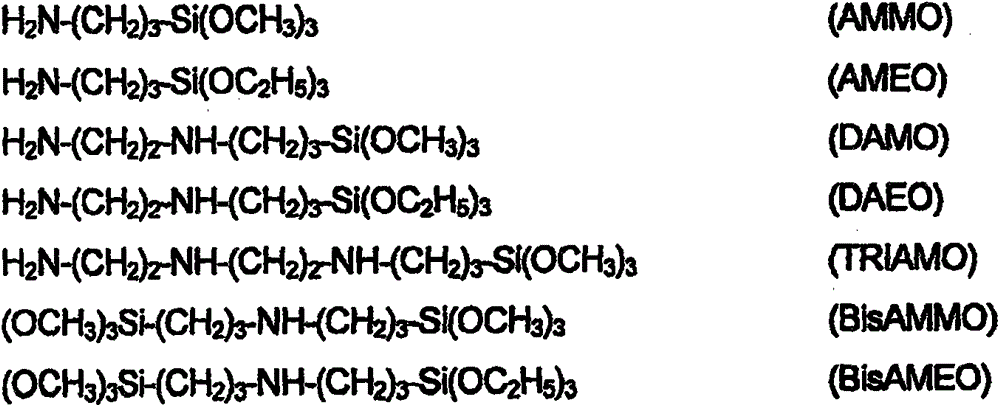

Method used

Image

Examples

Embodiment 1

[0100] Preparation of sol-gel system 1

[0101] device:

[0102] Stirred reactor with distillation unit, vacuum pump

[0103] Metering device, liquid phase (sumpf-) and top thermometer.

[0104] method:

[0105] Introducing 415.6g of GLYMO was used as starting material and 20.6 g of acetic acid was added with stirring. Immediately thereafter metered in 41.1 g NPZ. After 5 minutes the temperature increased by about 2-5°C. Then stir 417.0 g of 100S / 45% (aqueous silica sol with a solids content of 45% by weight). Ensure good stirring action. Immediately thereafter, 477.3 g of DI water was added dropwise and accelerated again. The opaque dispersion was further stirred at 75-80°C (reflux) for 2 hours when the maximum temperature was reached (about 42°C). After cooling the dispersion to a liquidus temperature of about 50° C., 356.4 g of DI water were post-metered in. Methanol is then distilled off at a liquidus temperature of about 50-60° C. and an absolute pressure o...

Embodiment 2

[0124] Water dilutability of the sol-gel systems of Example 1 and Comparative Example 1a

[0125] The products of Example 1 and Comparative Example 1a were diluted 1:1 with DI water and stored at 50°C. In the product of comparative example 1a, but not in the product of example 1, significant precipitation occurred after several days of storage.

[0126] In summary: only the product of Example 1 is stable on storage when diluted with water.

[0127] Storage-stable water-diluted products are very important for practical application in spraying and dipping if low dry layer thicknesses of 1 μm and lower are to be achieved.

Embodiment 3

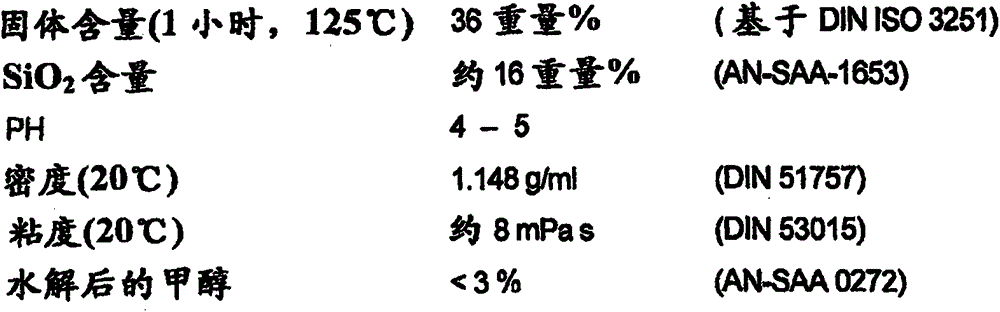

[0129] Preparation of neutralized sol-gel systems

[0130] The product of Example 1 was added to a stirred vessel and, under thorough stirring, 1151 (Degussa's aqueous aminosilane hydrolyzate) continuously monitors pH. Dosing 1151 until the composition reaches a pH of 7. The resulting product was stable for more than 4 months when stored at room temperature. pH changes during storage. The pH was 6 at the end of the storage period.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com