Rail track measuring mark point positioning method

A railway track and positioning method technology, which is applied in the direction of track, measuring instrument, track maintenance, etc., can solve the problems of low automation, low efficiency, high cost, etc., and achieve the effects of reducing labor costs, simple measurement and positioning process, and small divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

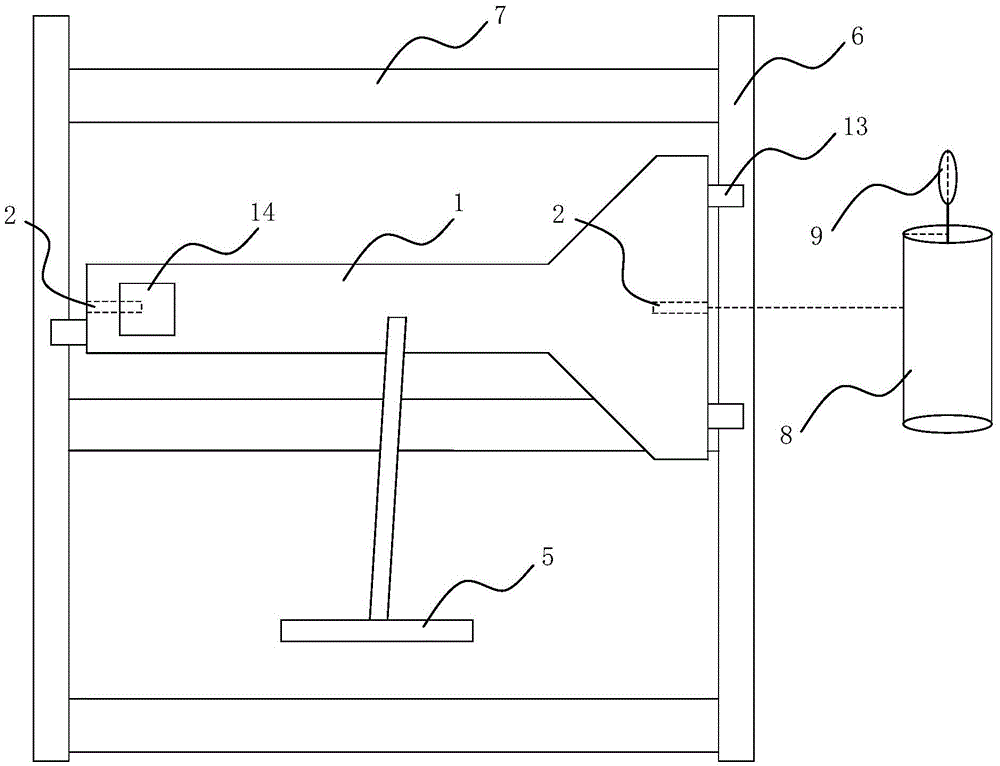

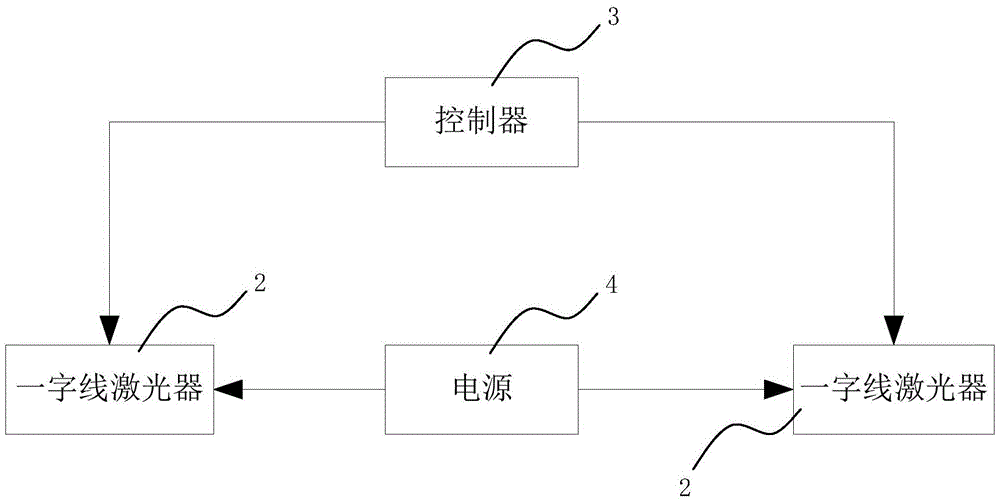

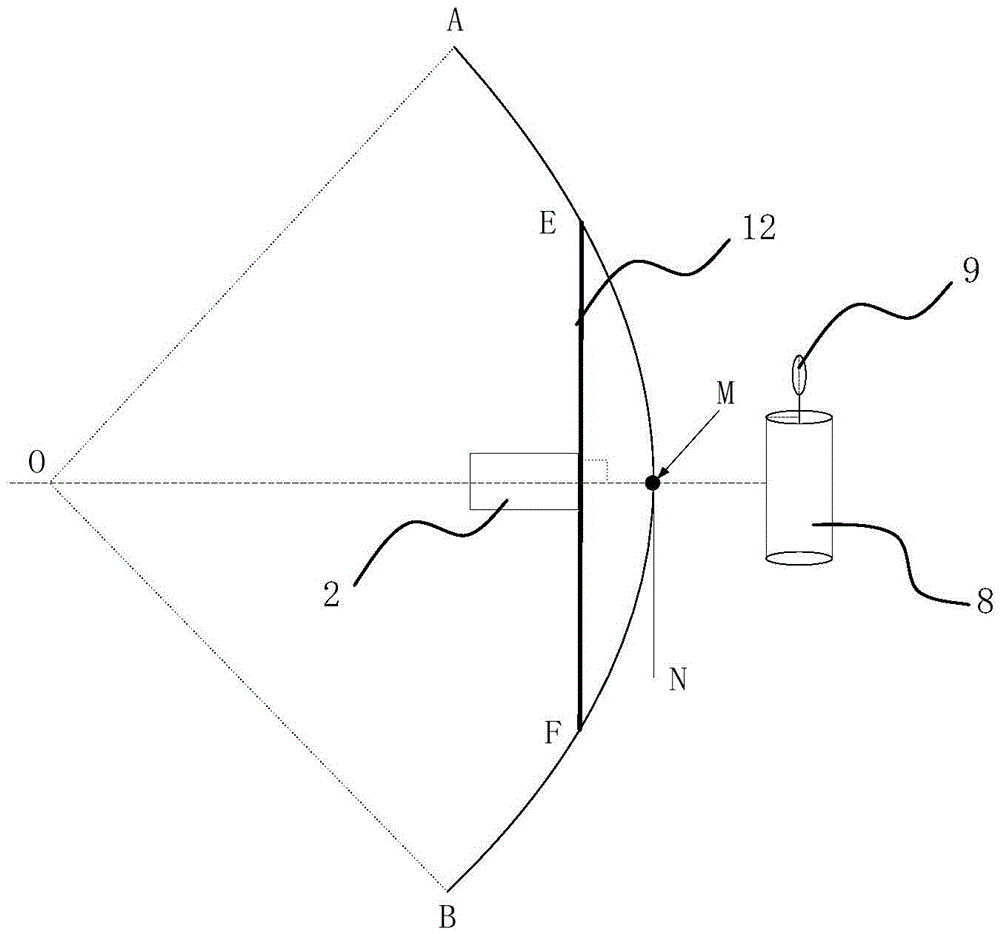

Embodiment Construction

[0030] For the sake of reference and clarity, the technical terms, abbreviations or abbreviations used below are recorded as follows:

[0031] CPⅢ: The abbreviation of foundation pile control network, a three-dimensional control network proposed by the former Ministry of Railways of the People's Republic of China to be laid along the railway line. Starting from the second-class level network laid along the line, it is usually measured after the completion of the offline engineering construction, which is the benchmark for track laying and operation and maintenance.

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com