Fabricated combined bridge deck structure provided with grid type connector and construction method thereof

A combined bridge deck and assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of reducing the service life of bridge deck pavement, difficult to control production costs, long construction period, etc., to achieve enhanced anti-corrosion The ability to slip between layers, reduce the risk of cracking, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

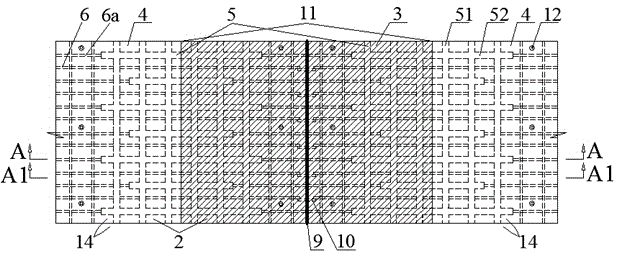

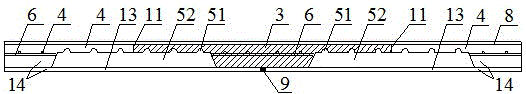

[0034] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

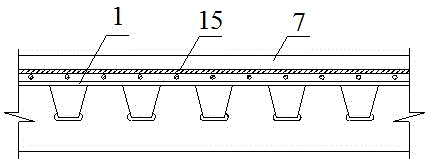

[0035] refer to Figure 1 to Figure 6, an assembled composite deck structure with grid joints, the composite deck structure includes at least two steel plate-fiber concrete composite members 14 assembled; the steel plate-fiber concrete composite member 14 includes a steel bridge at the lower part The panel 13 and the prefabricated fiber concrete part 4 poured on the steel bridge deck 13; the butt joint area of two adjacent steel plate-fiber concrete composite members 14 is provided with a grid joint; the grid joint includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com