Drill tool centralizing pup

A pup joint and drilling tool technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the damage of drilling tool centering tools in the performance range, and the inability of drilling tool centering tools to reduce wear, torque, centering, frictional resistance and Torque increase and other problems can be achieved to improve drilling efficiency, reduce direct contact and increase extension distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

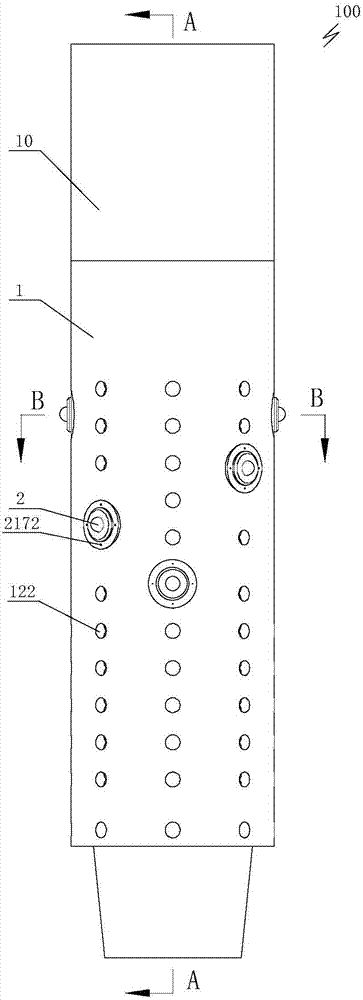

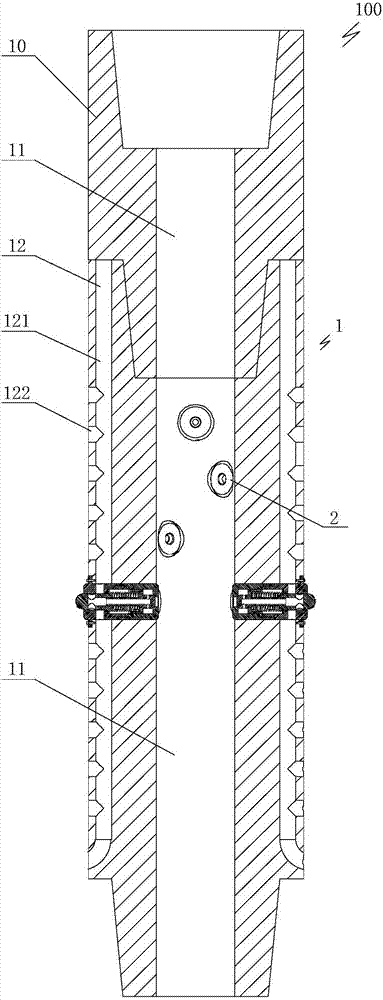

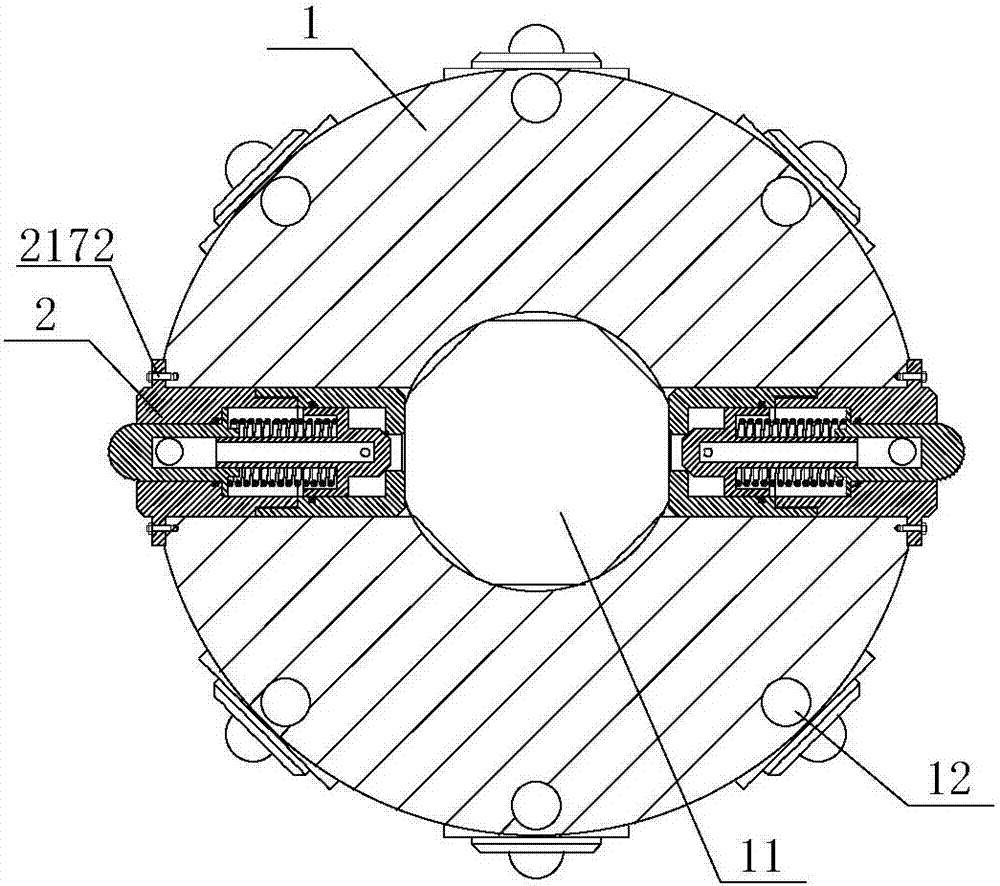

[0030] Such as figure 1 , figure 2 , image 3 As shown, the drilling tool straightening nipple 100 provided by the present invention includes a nipple body 1, and the inside of the nipple body 1 is provided with a drilling fluid flow channel 11 that penetrates up and down. not shown), the inner top of the puppet body 1 is connected with a connection joint 10, during use, the puppet body 1 is connected to the drill pipe (the prior art, not shown in the figure) through the connection joint 10, the pup joint body 1 The inner bottom of the drill pipe is threadedly connected to the lower section of the drill pipe or the drill bit (the prior art, not shown in the figure); the side wall of the nipple body 1 is uniformly fixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com