A self-cooling disc brake device

An automatic cooling and braking device technology, applied in the direction of brake types, brake parts, mechanical equipment, etc., can solve problems such as road safety accidents, overheating and cracking of brake discs, rapid heat accumulation, etc., to improve cooling effect, Good cooling effect and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

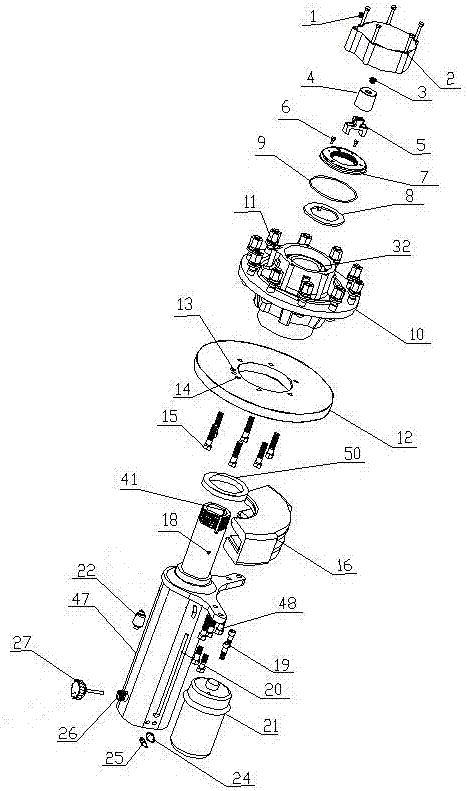

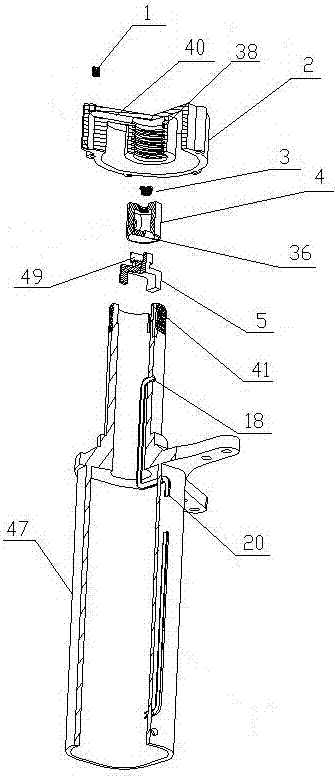

[0037] Such as figure 1 and Figure 7 A self-cooling disc brake device shown includes a disc brake caliper 16 and a brake chamber 21 fixed on the axle housing 47 through the A screw rod 48 and the B screw rod 19 respectively, and is rotatably connected to the The hub assembly 10 of the axle housing 47, the side of the hub assembly 10 facing the disc brake caliper 16 is fixed with the brake disc 12 through the C screw 15, and the bearing hole of the hub assembly 10 is installed towards the end of the brake disc 12 There is an oil seal 50, and the other end towards the end of the axle housing 47 is sequentially installed with a nut sealing ring 9, a shaft head locking piece 8 and a shaft head locking nut 7, and the nut sealing ring 9 and the oil seal 50 make the hub assembly Both ends of the bearing holes formed into 10 are sealed, and the other side of the wheel hub assembly 10 opposite to the brake disc 12 is also equipped with a shaft head cover 2 covering the bearing holes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com