A fast-connection structure of water hose and rigid joint

A technology of rigid joints and soft water pipes, which is applied in the direction of hose connection devices, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of easy aging of rubber gaskets, difficulty in tightening, and high requirements for anti-seepage, and achieves convenient operation, Strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

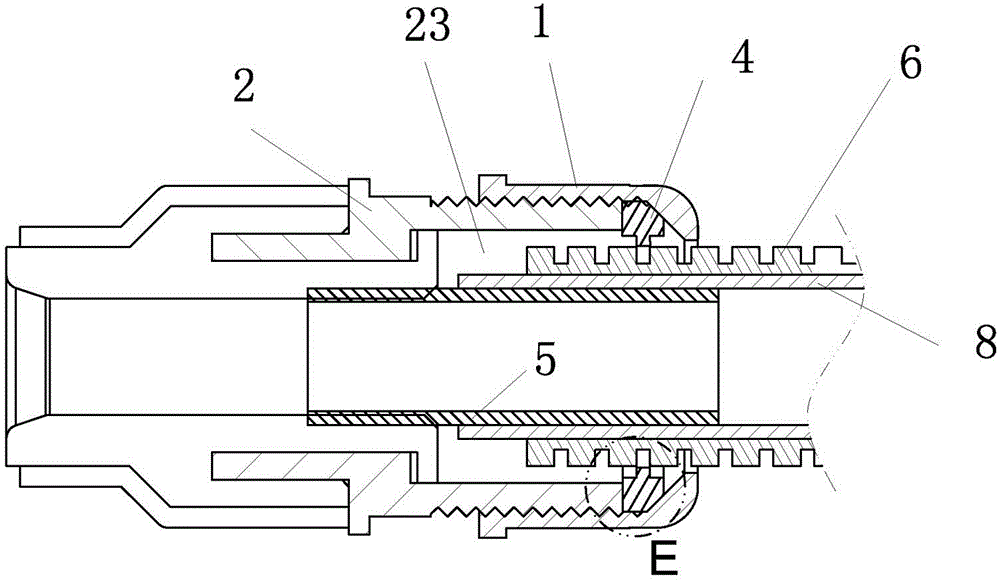

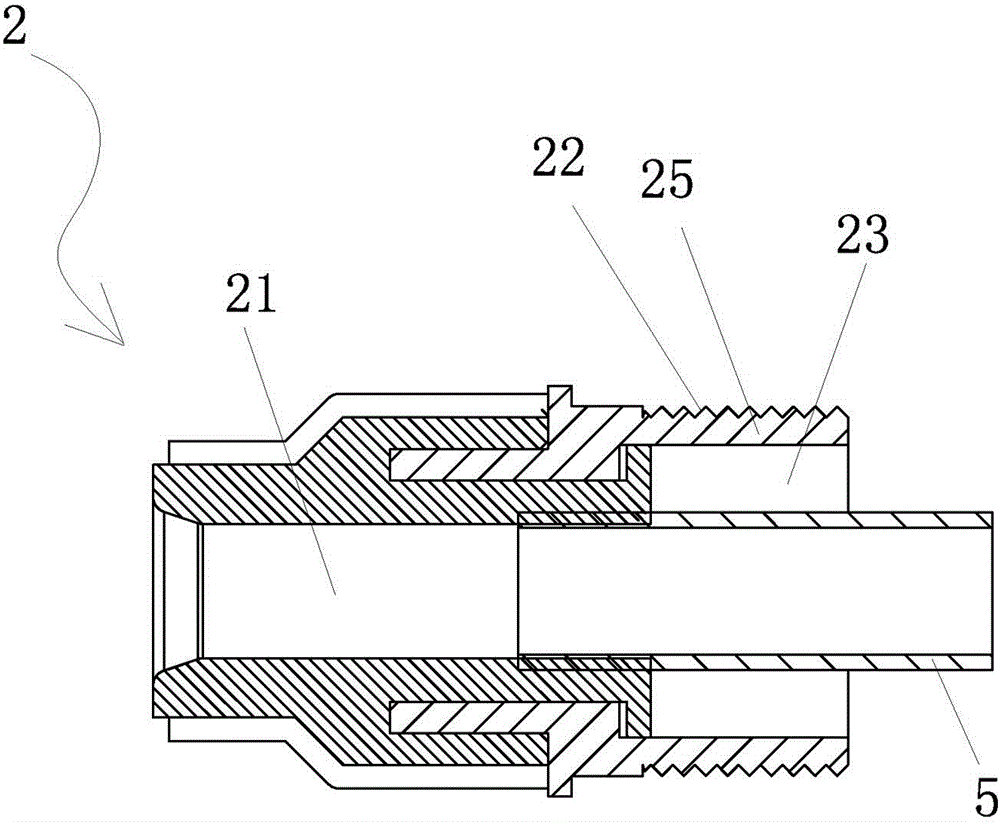

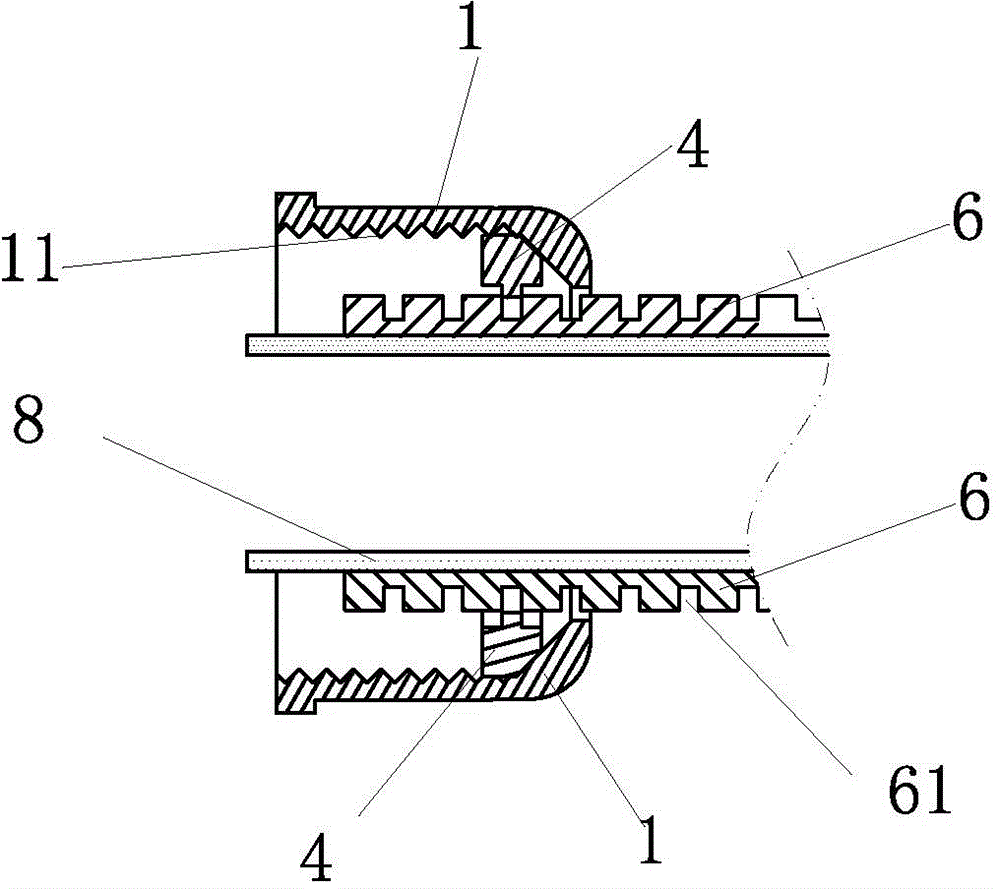

[0034] figure 1 , figure 2 , image 3 , Figure 7 As shown, the quick connection structure between the soft water pipe and the rigid joint includes a soft water pipe 8 (silicone tube), a nut cap 1, a hollow rigid joint body 2, the rigid joint body 2 is formed with a water hole 21, and the outer surface of the rigid joint body 2 The section is formed with an external thread 22, and the nut cap 1 is formed with an internal thread 11 that cooperates with the rigid joint body. After normal assembly, the nut cap 1 is screwed on the outside of the rigid joint body section 2; the cap center of the nut cap 1 is provided with a soft The hollow hole 12 through which the water pipe passes; the water hole 21 of the rigid joint body 2 is fixed and tightly connected with a rigid inner insertion tube 5, the rigid inner insertion tube is a stainless steel tube, and the inner end of the rigid inner insertion tube 5 is fixed and tightly fitted and inserted into the rigid joint In the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com