Internal strengthening and reinforcing method and strengthening combined structure for PCCP (prestressed concrete cylinder pipes) with broken wires

A composite structure and reinforcement technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of high cost of reinforced composite structures, poor adaptability to deformation, and infeasibility of urban engineering, etc., to achieve Excellent anti-seepage effect, good anti-abrasion performance, and solve the effect of insufficient bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

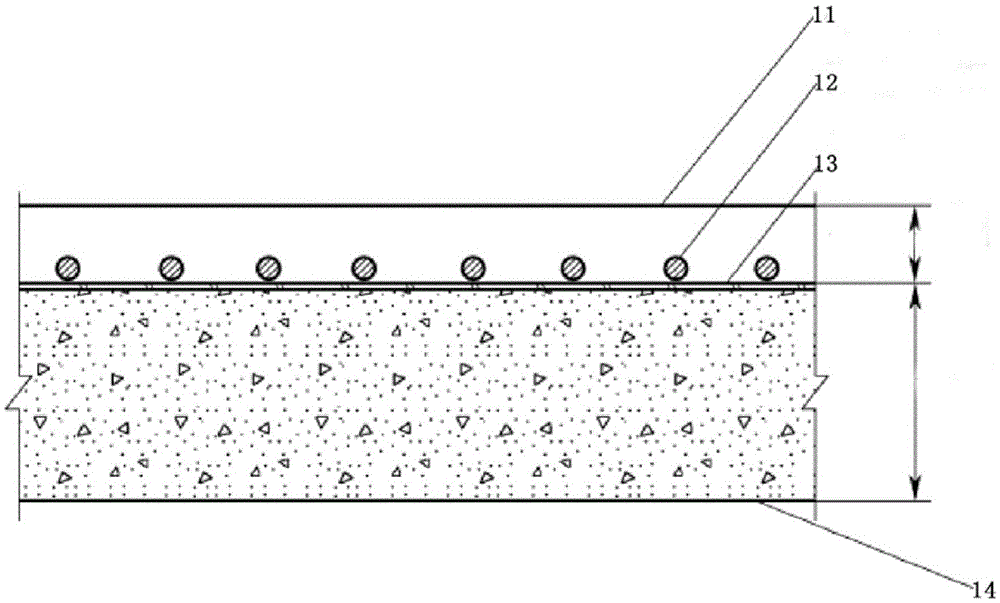

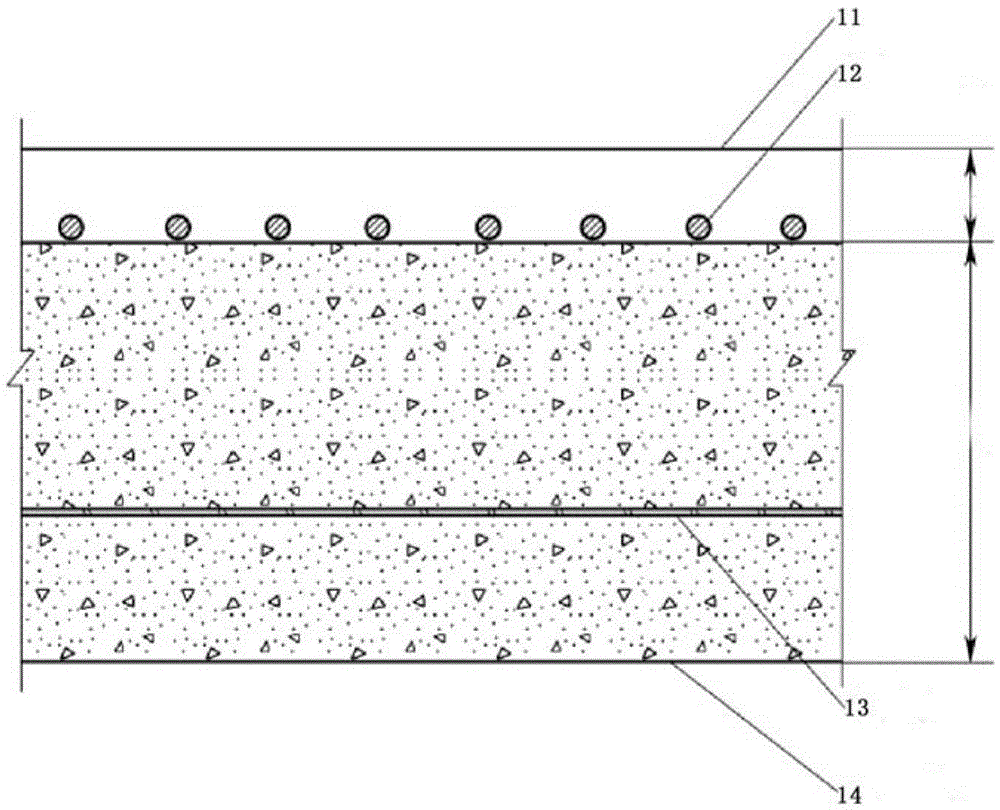

[0037] There are two types of prestressed steel cylinder concrete pipe PCCP: the first type of prestressed steel cylinder concrete pipe, please refer to figure 1 As shown, the concrete tube core includes a steel cylinder and a lined concrete tube 14, a high-strength stress steel wire 12 directly wound on the outside of the steel tube and a layer of protective mortar 11 on the outside of the steel tube 13 to form a lined prestressed steel cylinder concrete Pressure pipe (PCCPL); the second type of prestressed steel cylinder concrete pipe, please refer to figure 2 As shown, the steel cylinder of the concrete pipe core is embedded in the pipe core concrete 14, and the high-strength prestressed steel wire 12 wound on the surface of the outer concrete 14 has a layer of protective mortar 11 on the outside of the prestressed steel wire, forming an embedded prestressed steel wire together. Stressed steel cylinder concrete pressure pipe (PCCPE). In traditional construction, embedded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com