A positioning system and method for an inner circle cutting fixture

A positioning system and circular cutting technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of inability to monitor in real time, low precision and insufficient stability of inner circle cutting fixtures, etc., and achieve visual fixture positioning and reduce cutting costs. Cost, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

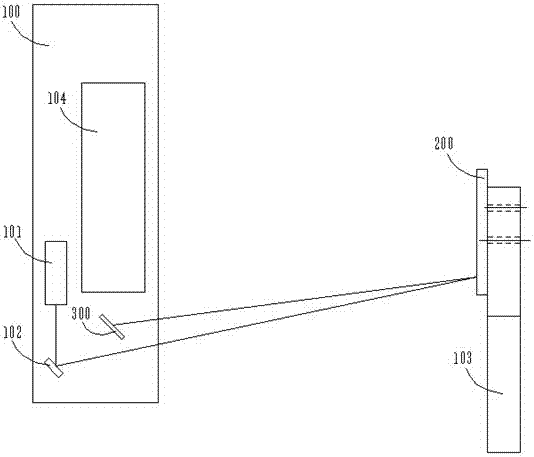

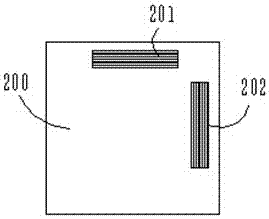

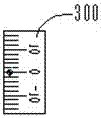

[0037] A positioning system for an inner circle cutting fixture, including two grating elements, a single-wavelength laser 101 , a device holder 100 , a third mirror 102 , a clamping fixture 103 , a grating element fixture 200 , a scale plate 300 and a monitoring lens 104 . The clamping fixture 103 and the device holder 100 are arranged side by side at a certain distance; the first grating element 201 and the second grating element 202 are embedded in the grating element fixture 200, and the angle formed by the direction of the grating grooves of the two grating elements is 90° degree; the plane of the grating element fixture 200 is parallel to the plane of the clamping fixture 103, and the plane of the grating element fixture 200 can rotate around a central axis; It is fixed on the device holder 100 , and the third mirror 102 is fixed in the beam emitting direction of the single-wavelength laser 101 . The light beam emitted by the single-wavelength laser 101 is refracted onto...

Embodiment 2

[0041] Such as Figure 4 As shown, a positioning system for an inner circle cutting fixture includes three grating elements, a single-wavelength laser 101, a device holder 100, a first reflector 402, a second reflector 405, a clamping fixture 103, a grating element fixture 200, and a scale Board 300 and surveillance lens 104. The clamping fixture 103 is arranged side by side with a certain distance from the device holder 100; the grating element has a line density of 1100 lines / mm, and includes a third grating element 501, a fourth grating element 502, and a fourth grating element embedded in the grating element fixture 200. Five grating elements 503, the angle formed by the grating groove directions of adjacent grating elements is 120 degrees; the plane of the grating element fixture 200 is parallel to the plane of the clamping fixture, and the plane of the grating element fixture can rotate around a central axis; the single wavelength The laser 101, the first reflector 402,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com