Directional-reflection-ball-based three dimensional calibration apparatus

A directional reflection sphere, three-dimensional calibration technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of less calibration information and complicated operation, and achieve the effect of large amount of information, good structural stability and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

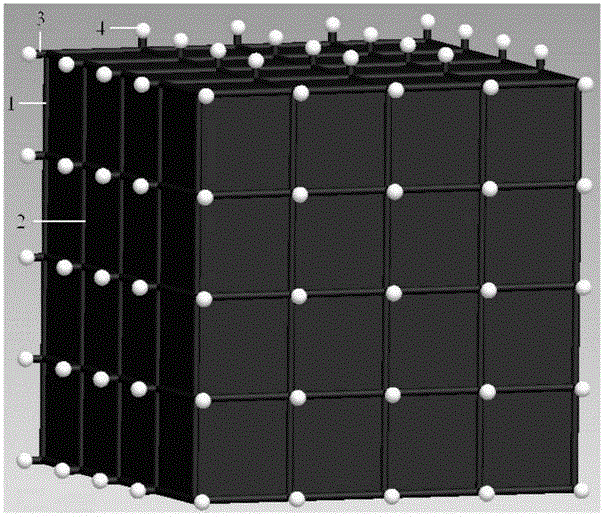

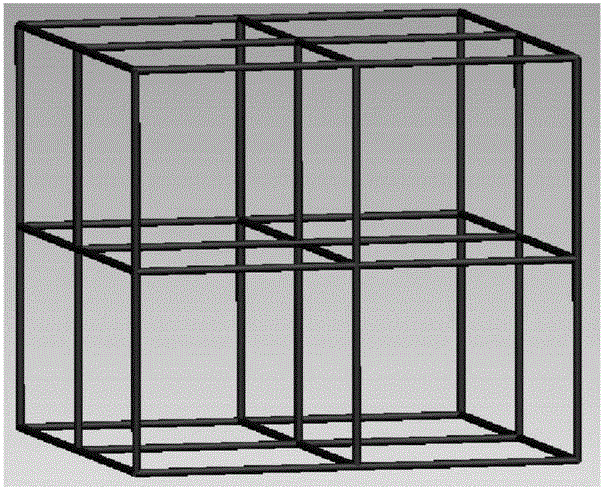

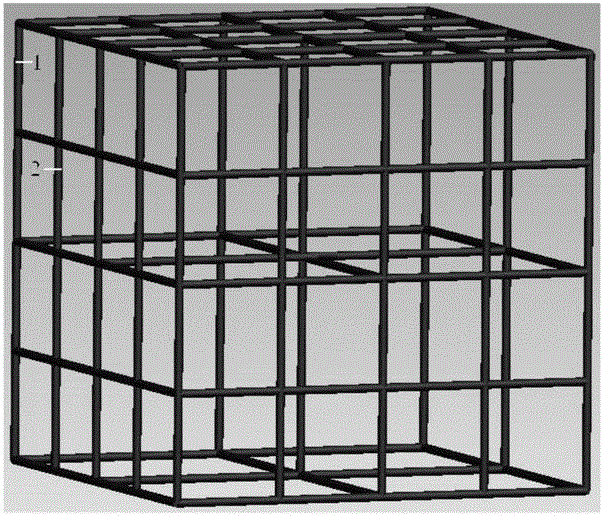

[0023] The following describes a three-dimensional calibration device based on the directional reflecting ball of the present invention with reference to the accompanying drawings and embodiments:

[0024] Such as Figure 1-4 As shown, a three-dimensional calibration device based on a directional reflection ball includes a base frame 1, a target position support structure 2, a reflection ball target position 3, and a directional reflection ball 4. Among them, the basic frame 1 is a cube frame or a hexahedron frame, and three adjacent surfaces of a square or rectangle are used as work installation surfaces. The target support structure 2 is a metal rod-shaped structure, which is installed on the top, front and left sides of the base frame 1. In this embodiment, the target support structure 2 is a rod-like shape with the same side length as the base frame 1. It is installed on the top, front and left sides of the base frame 1, and the two ends and the middle are respectively fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com