Preparation method of glass needle-shaped defect reflective electron microscope sample

A production method and electron microscope sample technology, applied in the field of glass, can solve problems such as difficult realization and low success rate, and achieve the effects of low cost, increased success rate, and improved glass quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is used to illustrate the preparation method of the glass needle-shaped defect reflection electron microscope sample of the present invention.

[0039] (1) Cut the non-defective glass and the defective glass into a size of 5mm×150mm×0.5mm;

[0040] (2) Place the defect-free glass in 10wt% HF solution, and after eroding for 1800s, measure the erosion depth with a metallographic microscope, which is 120 μm, and the erosion speed is 0.067 μm / s;

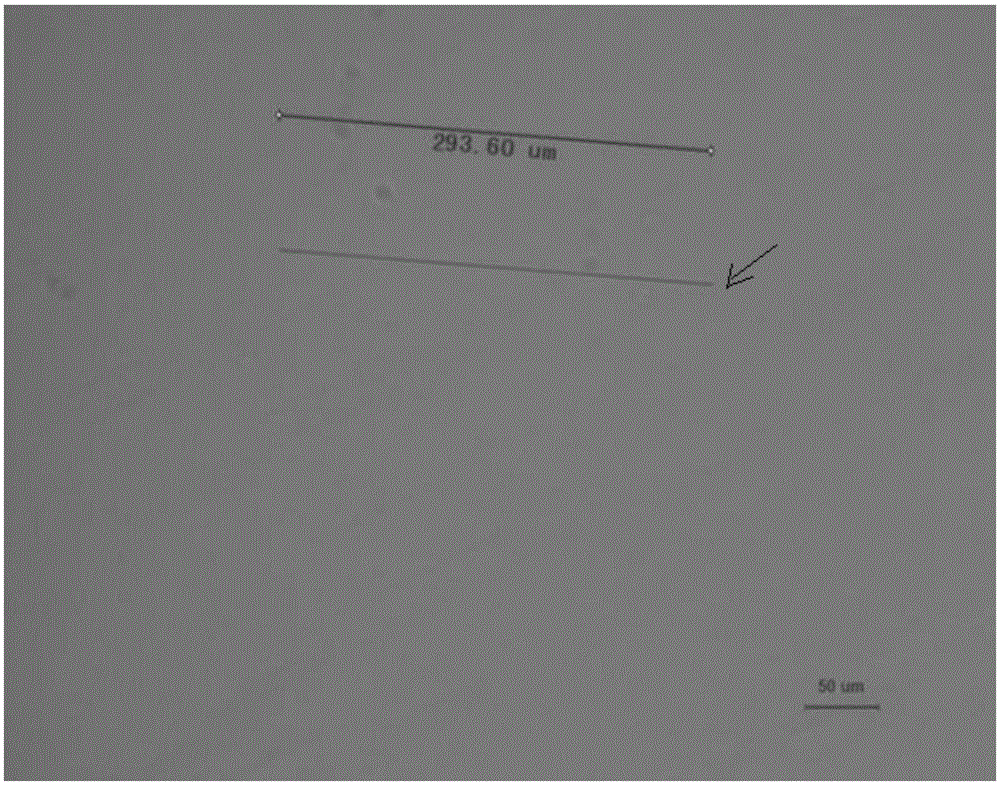

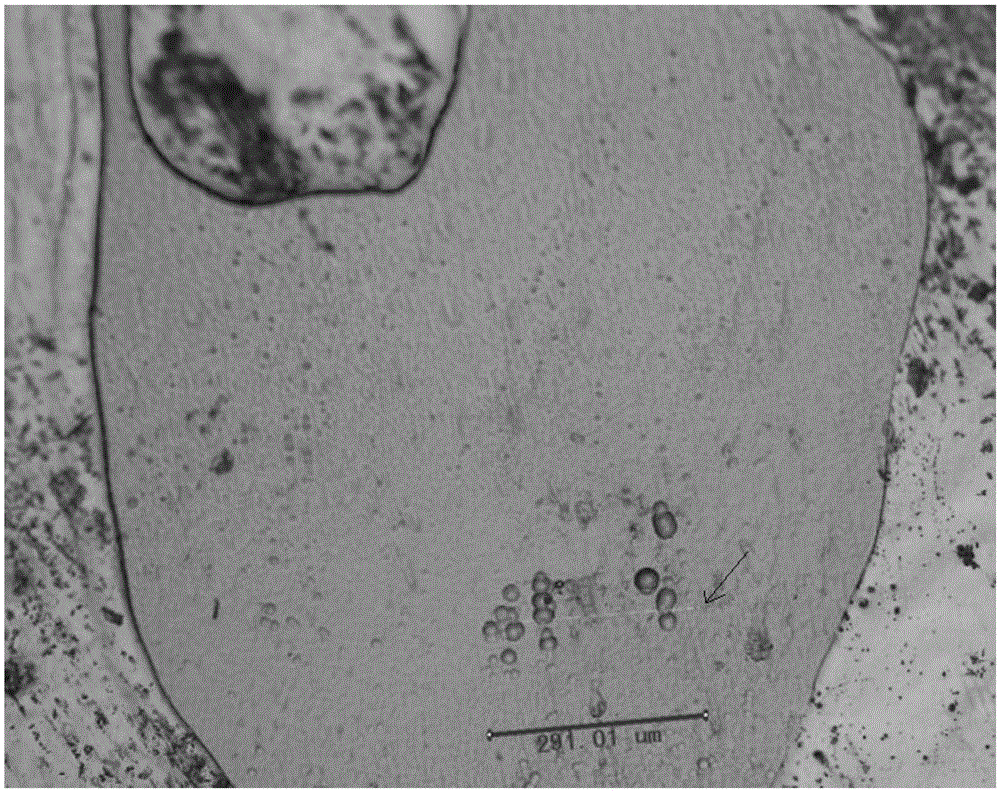

[0041] (3) Use a metallographic microscope to determine the size and position of the needle-like defects in the defective glass (such as figure 1 As shown, the length of the needle-shaped defect is 293.60 μm, and the diameter is 1.00 μm), and a circle is drawn at the position of the needle-shaped defect with a marker pen to mark, and the distance between the needle-shaped defect and the upper and lower surfaces of the defective glass is measured, respectively are 405 μm and 94 μm, according to the minimum distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com