Optical fiber fusion splicer objective lens manual pre-pairing device

A technology for connecting objects and optical fibers, which is applied in the field of manual pre-pairing devices for optical fiber fusion splicer objective lenses, can solve the problems of time-consuming, difficult production and debugging personnel, etc., and achieves the effect of saving time, saving installation and debugging, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

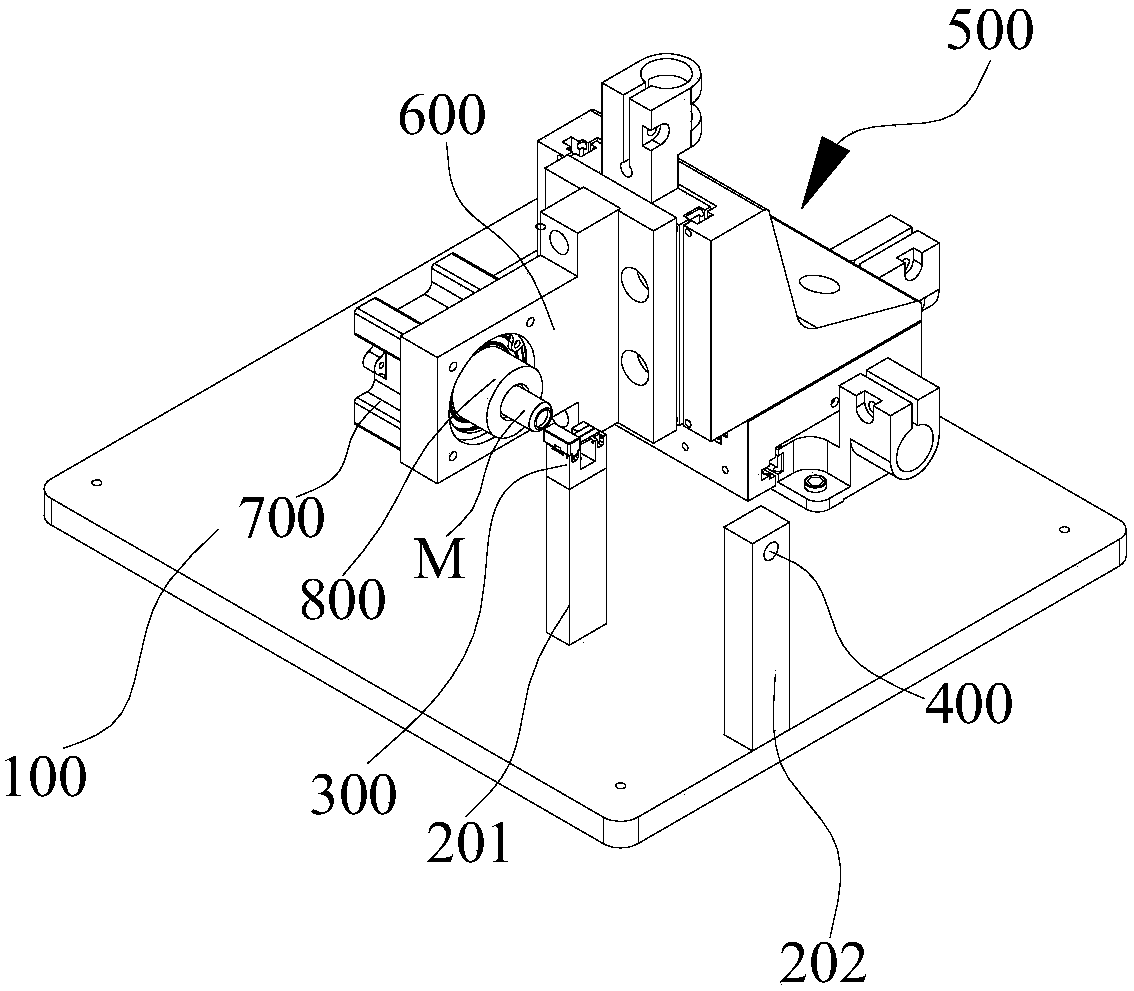

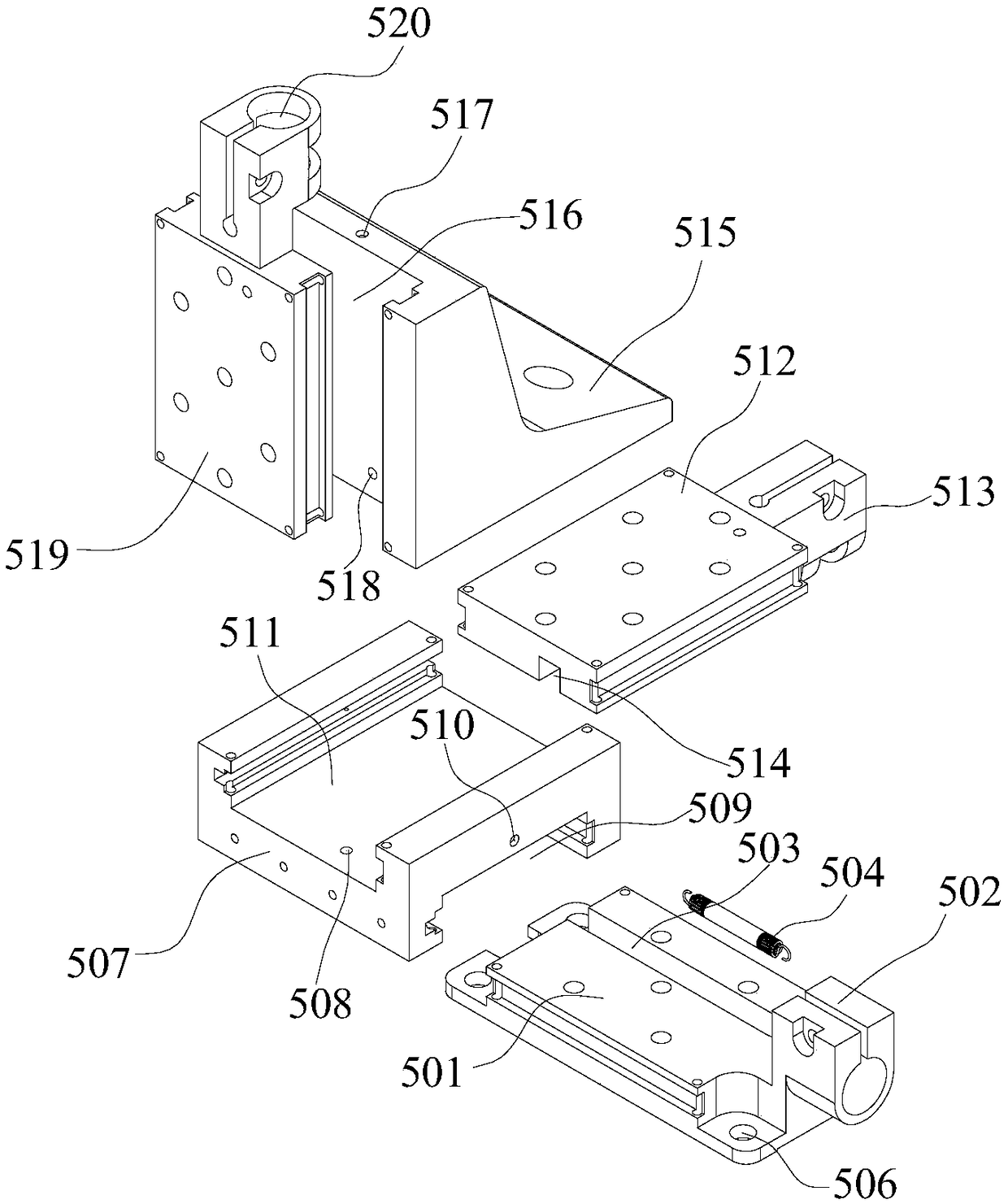

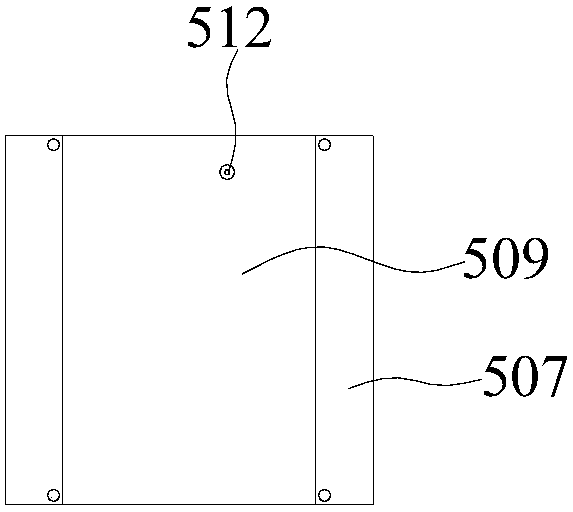

[0020] Optical fiber fusion splicer objective lens manual pre-pairing device, such as figure 1 As shown, it includes a three-dimensional manual adjustment mechanism 500, an objective lens holder 600, an optical fiber holder 300, and a light source 400. The three-dimensional manual adjustment mechanism 500 is composed of a base 510, front and rear adjustment sliders 507, left and right adjustment sliders 512, and up and down adjustment sliders 519. figure 2 As shown, the base 501 is rectangular, and each of the four corners of the base 501 has a mounting hole 506. The bolt passes through the mounting hole 506 to fix the base 501 on the bottom plate 100. The front end of the base 501 has a front and rear adjustment push rod seat 502, and the front and rear adjustment push rod seat 502 is provided. The rod is installed in the front and rear adjustment push r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap