High-strength high-voltage transmission power cable

A high-voltage power transmission and power cable technology, which is applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve problems such as difficulty in finding breakpoints, sliding friction, and short circuits in insulating layers, and achieve long-term large-scale Area blackout problem, resistivity reduction, hardness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

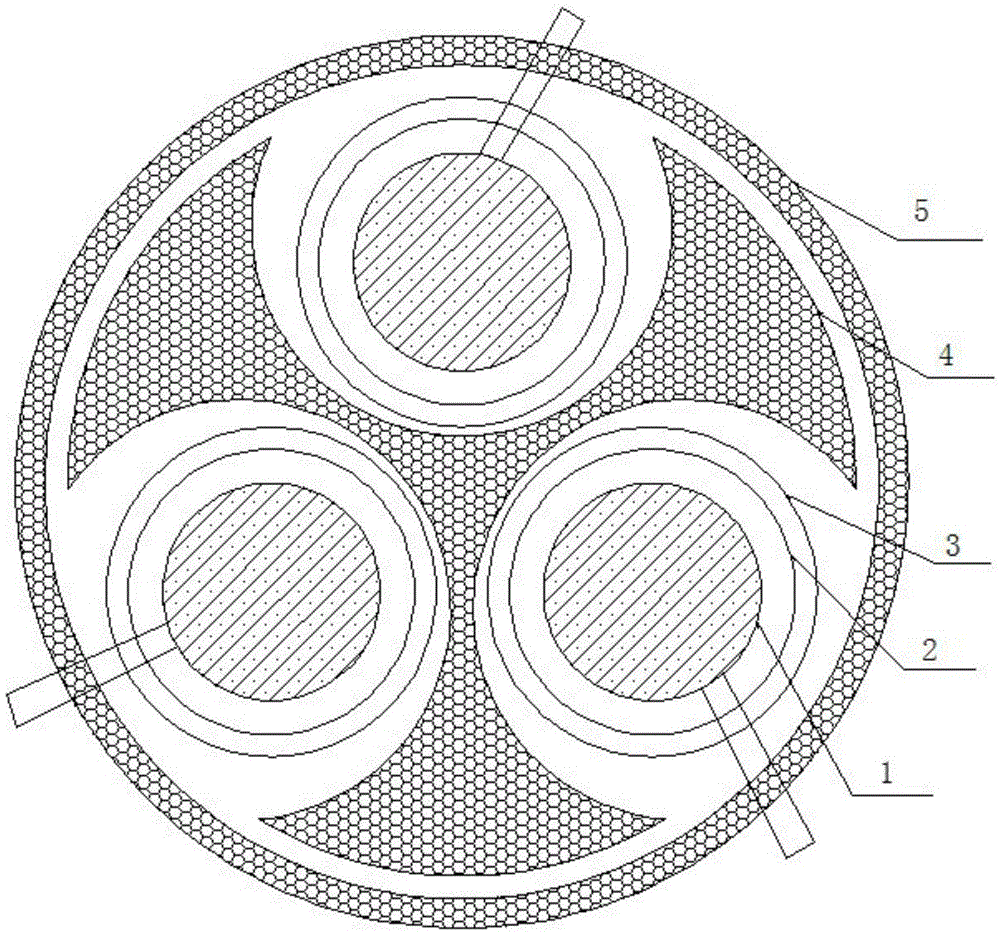

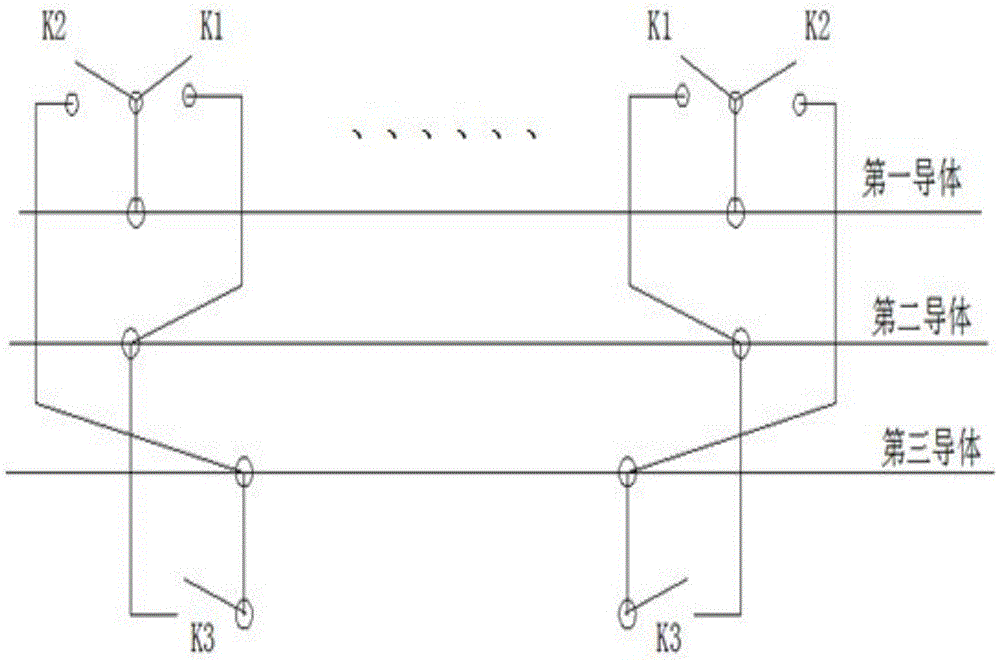

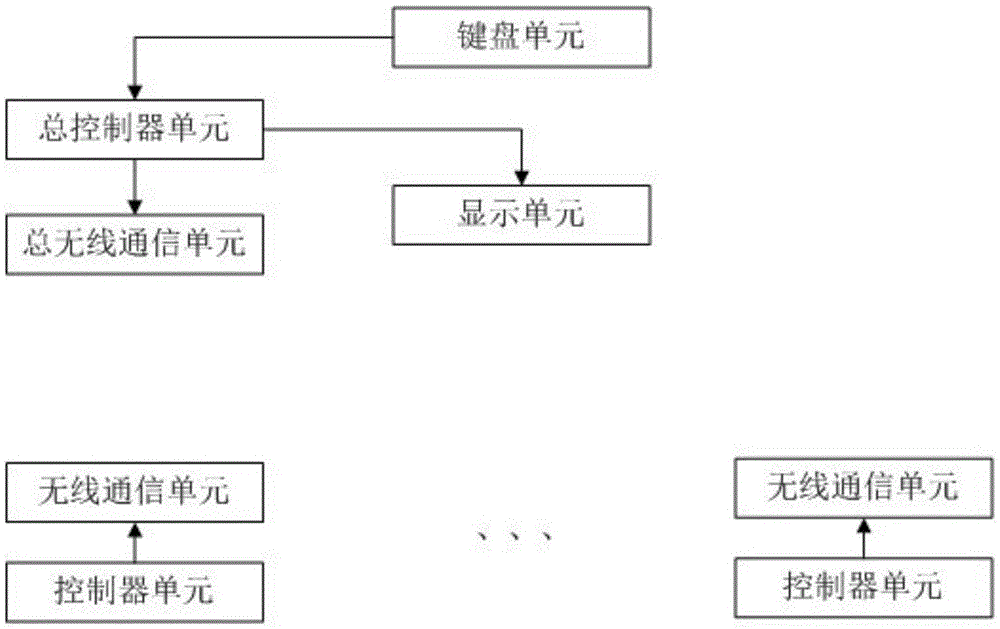

[0040] Embodiment 1: a high-strength high-voltage transmission power cable, including 3 conductors, a conductor shielding layer, an insulating layer, and a protective layer; the conductor shielding layer is arranged on the outside of the conductor, the insulating layer is arranged on the outside of the conductor shielding layer, and the three conductors are arranged on the In the protective layer; also includes a cylindrical fixing device, the cylindrical fixing device is located in the protective layer; the side of the cylindrical fixing device is equidistantly provided with 3 arc-shaped grooves; the 3 conductors are respectively located in the circular arc-shaped groove; the cavity formed between the conductor, the cylindrical fixing device, and the protective layer is filled with an insulating filler; it also includes a remote breakpoint detection unit and 6 terminal breakpoint detection units; the 6 The terminal breakpoint detection units are equidistantly arranged on the h...

Embodiment 2

[0058] On the basis of Embodiment 1, the first switch, the second switch, and the third switch all use controllable thyristors.

[0059] Wherein, the conductor is made of aluminum alloy material, and the weight ratio of the aluminum alloy material is as follows: aluminum: 1000 parts; samarium: 12 parts; molybdenum: 4 parts;

[0060] After preparing the aluminum alloy raw materials according to the above weight ratio, firstly, the melting temperature is 830°C, after stirring, degassing and refining with hexachlorobenzene, continuous casting is carried out using a continuous casting machine, and continuous casting is made into an aluminum alloy ingot of Φ120mm;

[0061] Then, an aluminum alloy rod of Φ35mm is made by hot extrusion at 420°C with an extruder;

[0062] Then, perform annealing treatment at 420°C for 50 hours;

[0063] Finally, a Φ4mm aluminum-sarium-molybdenum-molybdenum alloy wire was prepared by drawing eight times with a wire drawing machine.

Embodiment 3

[0065] Others are exactly the same as in Example 1, wherein the conductor is made of an aluminum alloy material, and the weight ratio of the aluminum alloy material is as follows:

[0066] Aluminum: 1000 parts; Samarium: 13 parts; Molybdenum: 5 parts;

[0067] After preparing the aluminum alloy raw materials according to the above weight ratio, firstly, the melting temperature is 830°C, after stirring, degassing and refining with hexachlorobenzene, continuous casting is carried out using a continuous casting machine, and continuous casting is made into an aluminum alloy ingot of Φ120mm;

[0068] Then, an aluminum alloy rod of Φ35mm is made by hot extrusion at 420°C with an extruder;

[0069] Then, perform annealing treatment at 420°C for 50 hours;

[0070] Finally, a Φ4mm aluminum-sarium-molybdenum-molybdenum alloy wire was prepared by drawing eight times with a wire drawing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com