Paying off apparatus

A technology of pay-off device and traction device, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problems of difficult operation, complex structure, and difficulty in flattening and straightening aluminum wires, and achieves the extension of walking path and volume Small, manageable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

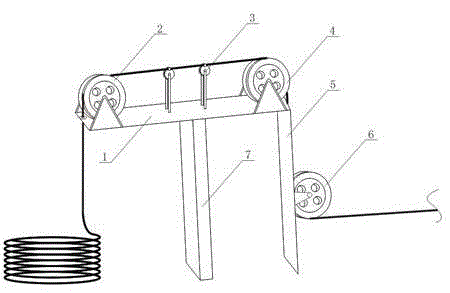

[0016] Such as figure 1 As shown, a pay-off device includes a bracket and a traction device fixed on the bracket. The bracket is an approximately "7"-shaped structure composed of a top plate 1 and a side plate 5 vertically connected. The traction device includes a traction wheel A2 , the traction wheel B4, the traction wheel C6 and the guide wheel 3, the traction wheel A2 and the traction wheel B4 are fixed on the upper surface of the top plate 1 through the support frame respectively, and the wheel grooves on the traction wheel A2 and the traction wheel B4 are opposite to each other , the top plate 1 is also provided with a guide wheel 3 between the traction wheel A2 and the traction wheel B4; the traction wheel C6 is fixed on the outer surface of the side plate 5 through a support frame.

[0017] The wheel groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com