Ultra-high-temperature and ultra-low-emission pulse dust collector

A pulse dust collector and ultra-high temperature technology, applied in chemical instruments and methods, dispersed particle filtration, gas treatment, etc., can solve problems such as high energy consumption, and achieve the effect of extending the walking path, improving the dust removal effect, and improving the blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

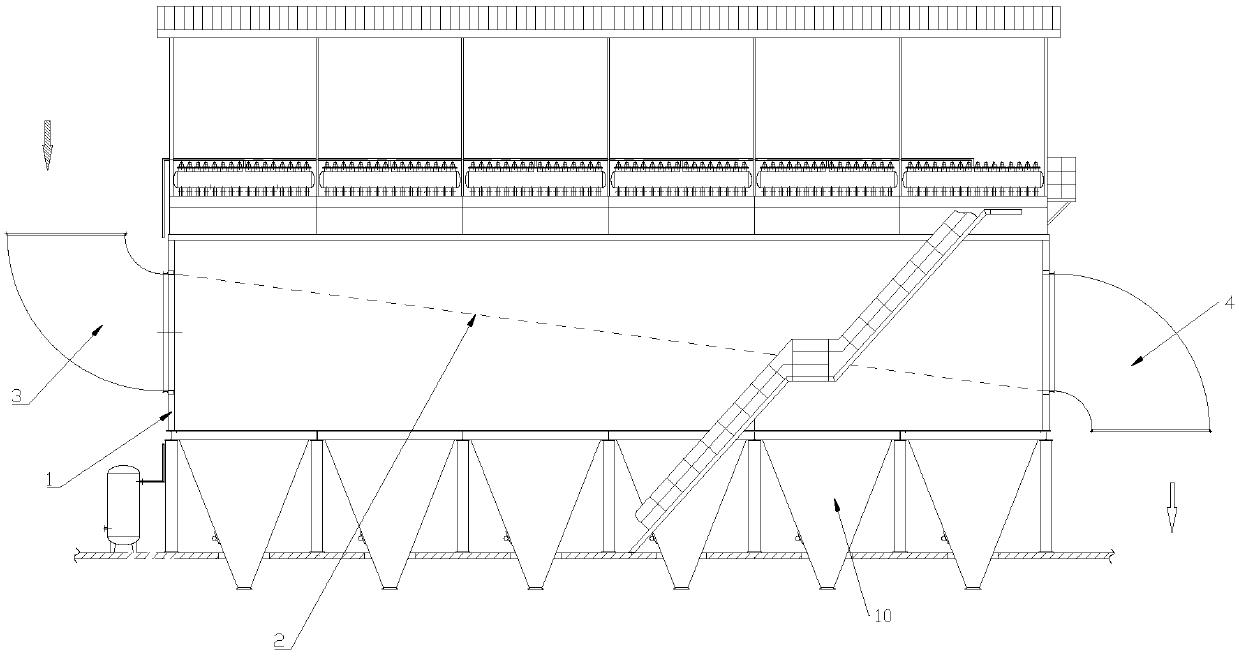

[0018] Such as figure 1 As shown, the present invention proposes a pulse dust collector with ultra-high temperature and ultra-low emission, comprising: dust removal box 1, partition plate 2, metal filter cartridge (not shown in the figure), air inlet pipe 3 and exhaust pipe 4, dust removal The box 1 is provided with an inner cavity, and a partition plate 2 is installed on the inner wall of the cavity. The partition plate 2 divides the inner cavity into an upper chamber and a lower chamber, an air inlet pipe and an exhaust pipe. There are at least three metal filter cartridges located in the vertical direction, the bottom of each metal filter cartridge communicates with the lower chamber, and the top of each metal filter cartridge is provided with a through hole that only communicates with the upper chamber. For air to pass through, an air inlet pipe 3 is installed at one end of the dust removal box 1, and the air inlet pipe 3 communicates with the lower chamber. At the positi...

Embodiment 2

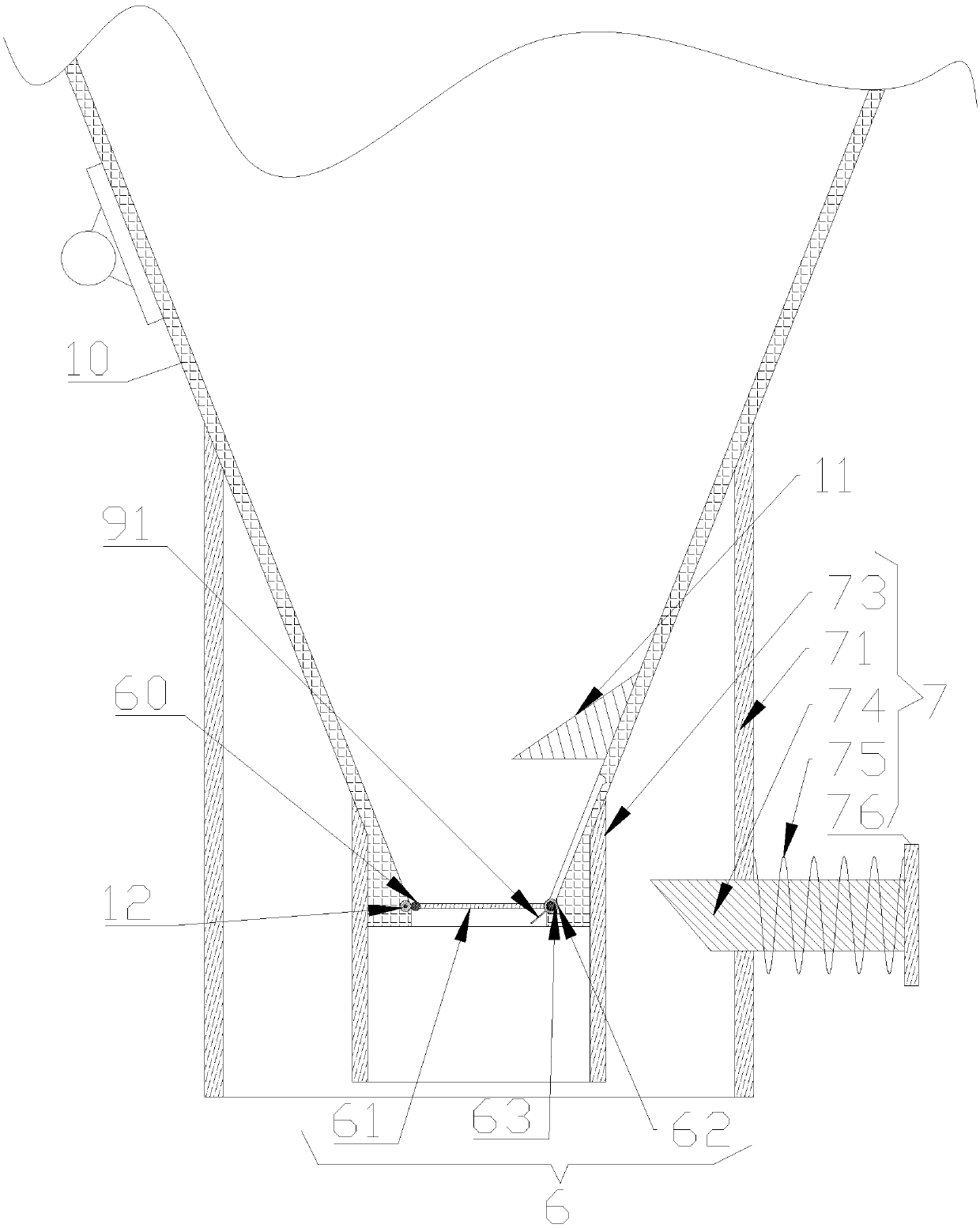

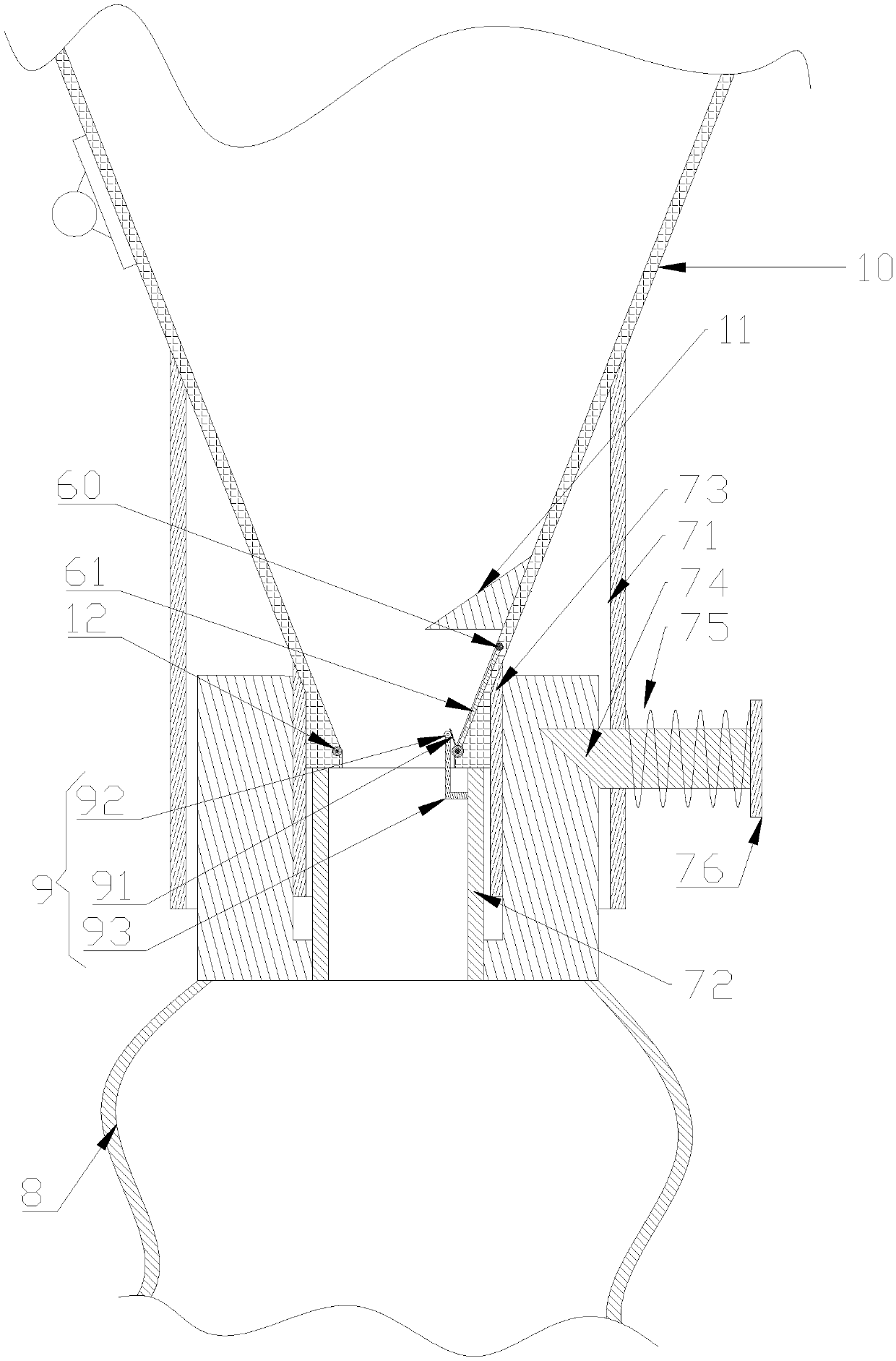

[0021] Such as figure 2 as well as image 3 As shown, the difference between this embodiment and Embodiment 1 is only that: in order to realize smooth discharge, an ash hopper 10 is installed at the bottom of the dust removal chamber to realize the deposition of dust, and an opening and closing mechanism 6 is installed at the bottom of the ash hopper 10 to realize Only after the ash container 8 is communicated with the ash hopper 10, the ash discharge pipe 5 is opened, which avoids the downward movement of dust in the ash hopper 10 when the ash container 8 is not installed.

[0022] The bottom of the dust removal chamber is connected to the large ends of several ash hoppers 10. The small ends of the ash hoppers 10 are located below the large ends of the ash hoppers 10. There are ash discharge pipes 5 connected to the small ends of the ash hoppers 10. The ash discharge pipes 5 are equipped with a switch for opening and closing. The opening and closing mechanism 6 of the ash d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com