Visual-assembly production line of motor rotor and assembly process

A technology for motor rotors and production lines, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as poor product quality, reduce labor force, and low efficiency, and achieve the effects of saving time, improving real-time performance, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

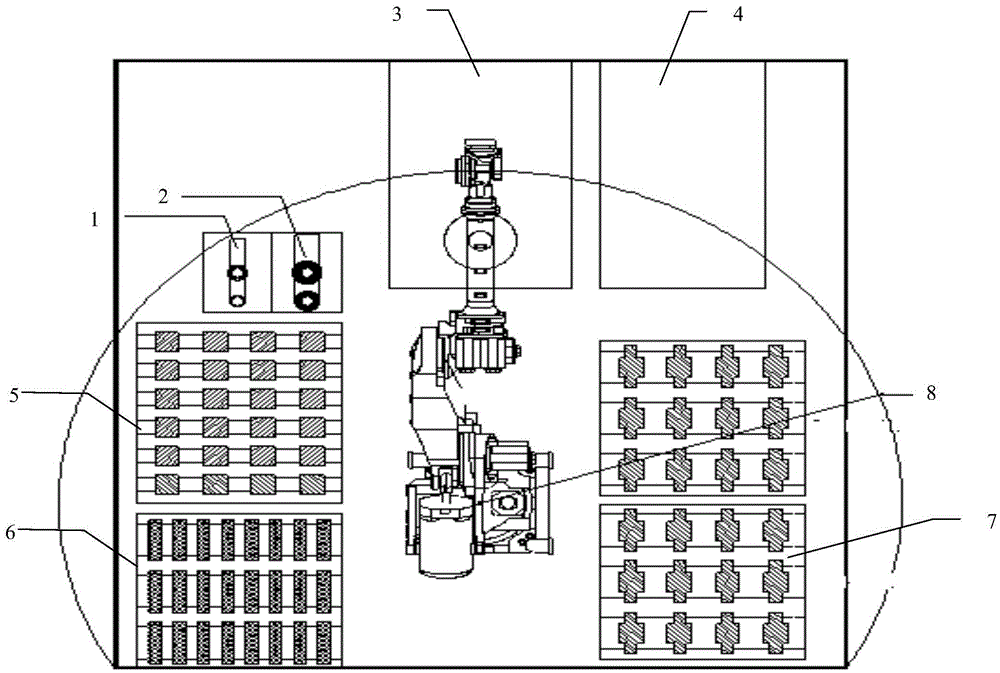

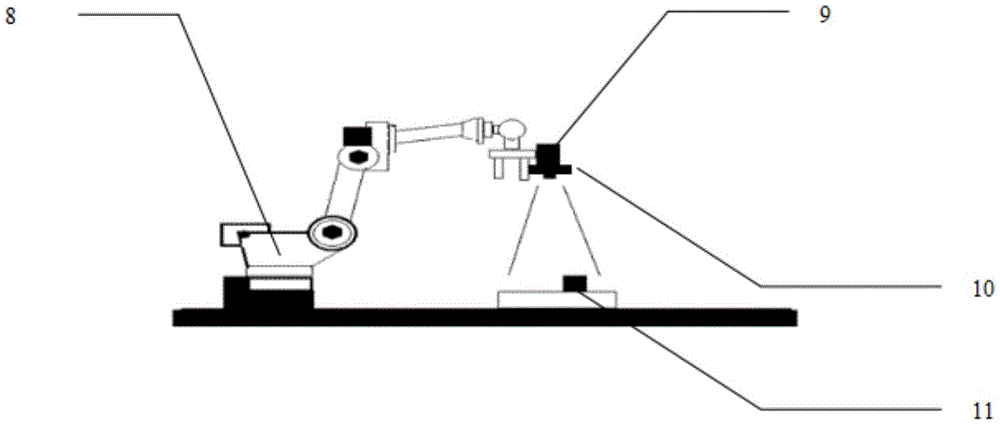

[0045] The motor rotor visual assembly production line in this embodiment includes shaft sleeve automatic discharge equipment 1, end plate automatic discharge equipment 2, single-arm hydraulic press 3, magnetic steel embedded equipment 4, rotor core tray 5, rotating shaft tray 6, and press-fit finished product tray 7 , robot 8, PLC (not shown in the figure), industrial camera 9, ring light source 10 and industrial tablet computer; wherein robot 8, PLC, single-arm hydraulic press 3, shaft sleeve automatic discharge equipment 1, rotor core tray 5, rotating shaft The pallet 6, the finished product pallet 7, the end plate automatic discharge equipment 2 and the magnetic steel equipment 4 form the robot execution system; the industrial camera 9, the ring light source 10 and the industrial tablet computer form the robot vision system;

[0046] The industrial camera 9 and the ring light source 10 are used to acquire images, and the industrial tablet computer is used to process the ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com