Optomechanical system for injecting light, optical coupler of said system, and illuminating device with said system

A mechanical system and optical coupling technology, applied in the direction of lighting devices, coupling of optical waveguides, light guides of lighting systems, etc., can solve the problems of complex design and manufacture, bulky emission system, etc., and achieve high-power applications and the best visual appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

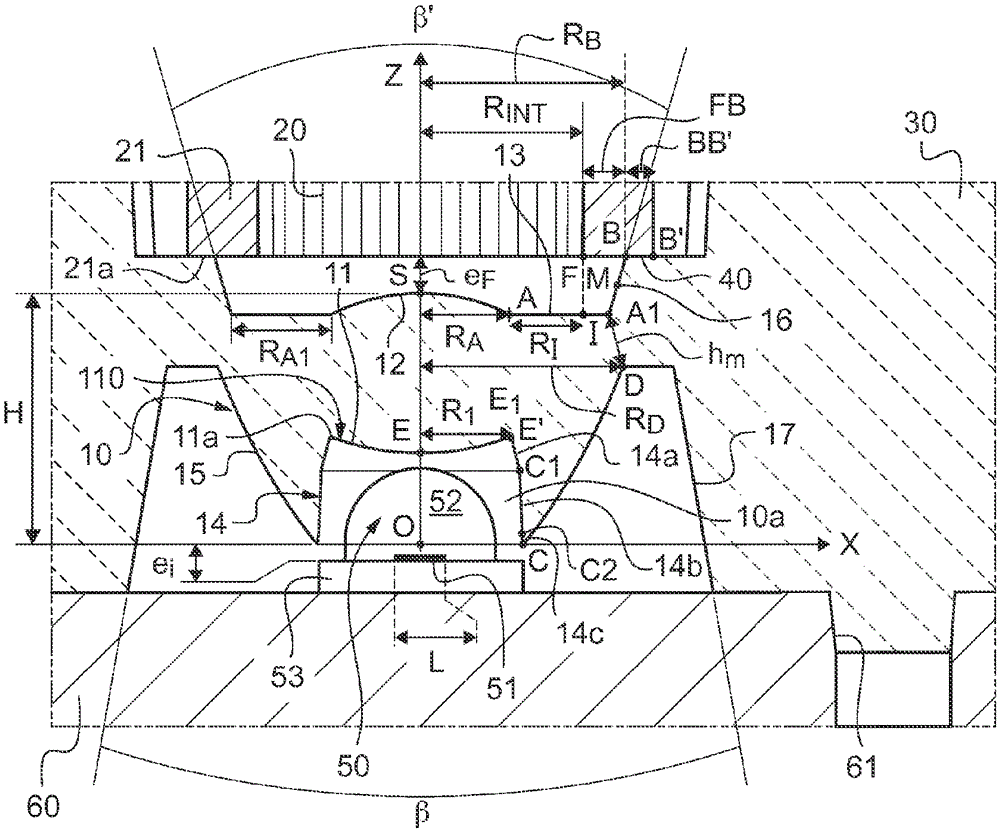

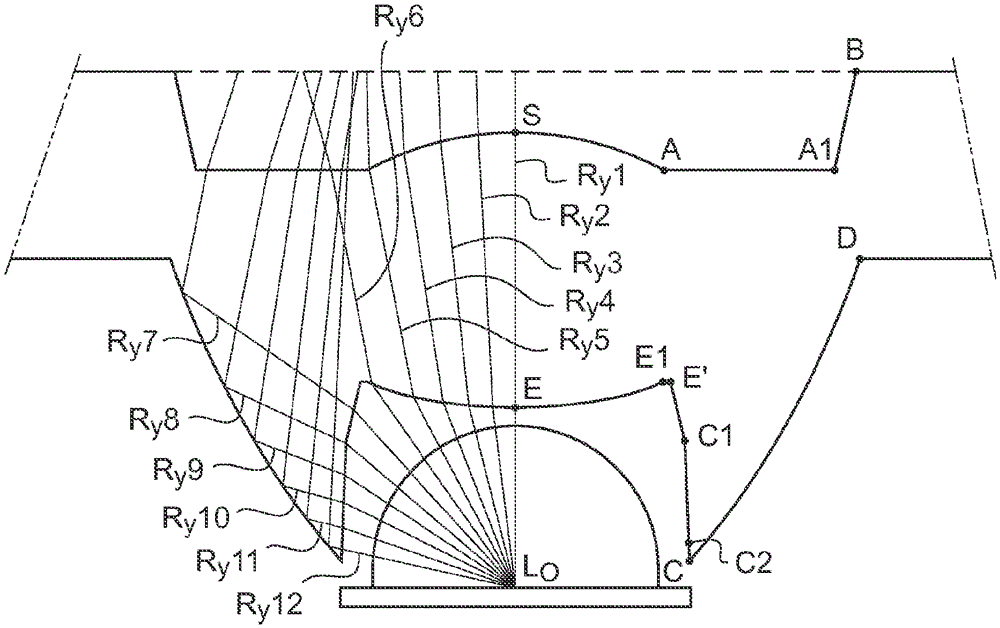

[0290] figure 2 (and image 3 , which is a detail view) shows a partial longitudinal cross-sectional view of an optomechanical system 1000 for a thin optical medium (preferably an emissive strip coupled to a light-emitting fabric) according to a first embodiment of the invention, said system comprising Optical coupler 1 comprising a transparent body obtained by molding made of PMMA (polymethyl methacrylate) with an optical refractive index n=1.5895 at 550 nm, said coupler being rotationally symmetric and having a central axis Oz, at One plane (O, X, Z) corresponding to the plane of the longitudinal section is shown and clearly defined, O being the center of the entrance of the optical coupler 1 .

[0291] image 3 The traces of each surface of the optical coupler in the longitudinal section plane are shown and representative points are defined for each section, for clarity only in the positive quadrant of the section plane.

[0292] Optical coupler 1 consists of:

[0293] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com