A production process of modified fiber board

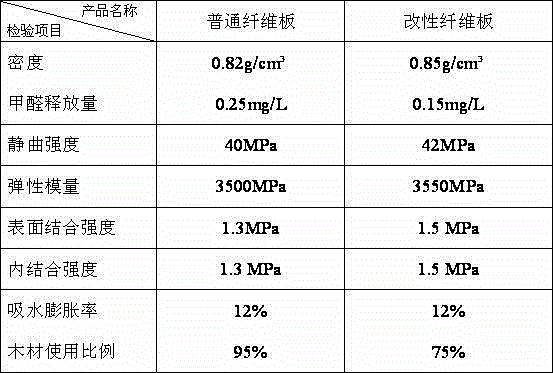

A technology of modified fiber and production process, which is applied in the direction of wood processing equipment, pretreatment of molding materials, manufacturing tools, etc. It can solve the problems of low strength of fiberboard, limited range of use, warping and deformation of the board, and achieve increased volume and Density, reduced wood consumption, and improved board performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

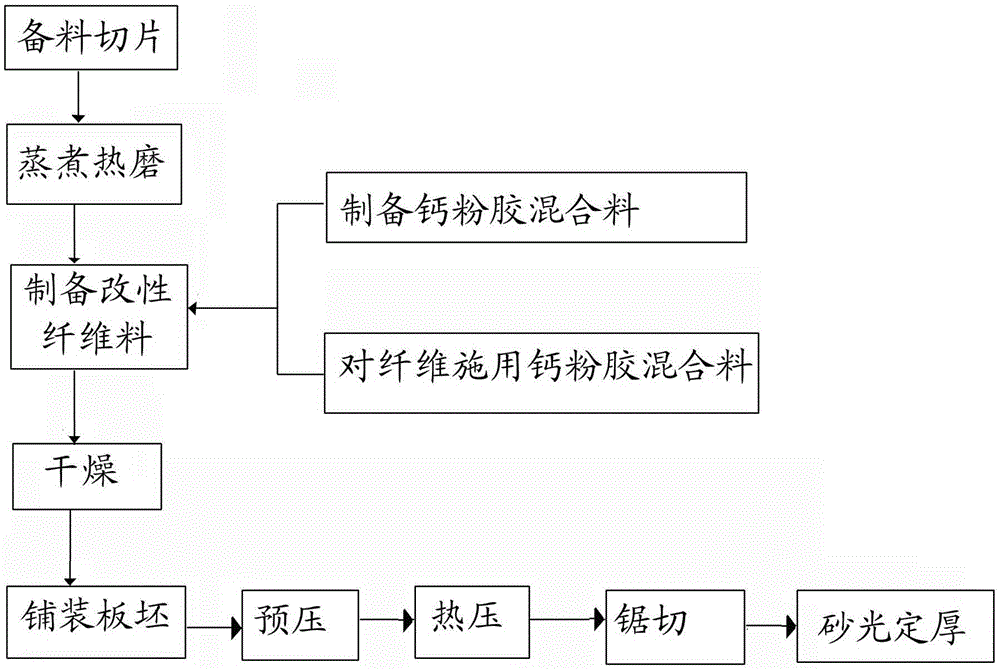

[0018] see figure 1 , the production process of the modified fiberboard of the present invention comprises steps such as chipping, cooking and hot grinding, preparation of modified fiber material, drying, preparation of blank material, cold pressing, hot pressing, sawing, sanding and thickness determination, each The specific steps are:

[0019] Step 1 chipping: the wooden material is cut into wood chips with a length of 3-5cm and a width of 2-3cm by a chipper. The woody material can be selected from trunk wood, branch wood, waste wood or other plant fiber raw materials. Like this, it can be Save a lot of round wood resources.

[0020] Step 2 Cooking and grinding: put the cut wood chips in step 1) into the cooking tank for cooking, the cooking temperature is 150-175°C, and the cooking time is 2-3 minutes, and then put the cooked wood chips into the heat grinder for heating Grind into fibrous fiber material with a heat grinding pressure of 7-8.55MPa to make the fibrous materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com