Water film pipe deduster

A dust collector and water film technology, applied in chemical instruments and methods, use of liquid separation agents, combined devices, etc., can solve problems affecting the life and work of surrounding and staff, discount of dust removal effect, dust filtration, and adsorption capacity of wet dust collectors Limited and other problems, to achieve the effect of improving the dust removal effect, improving the dust removal effect, and improving the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

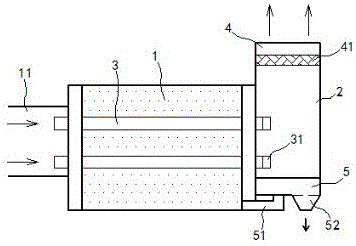

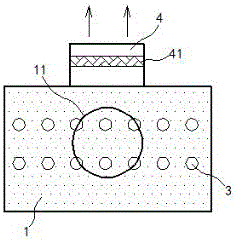

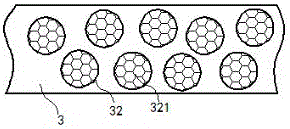

[0013] exist Figure 1 to Figure 3 In the shown embodiment, the water film tube dust collector includes a dust removal chamber 1 and a separation chamber 2, and the separation chamber 2 is placed on the right side of the dust removal chamber 1; the dust removal chamber 1 is filled with purified water, and the dust removal chamber 1 is filled with purified water. A viscous agent is added to the purified water; water film tubes 3 are arranged parallel and equidistant in the dust removal chamber 1, and the water film tubes 3 are made of hard materials. Water inlet holes 32 are provided equidistantly on the top; silk screens 321 are fixed at each of the water inlet holes 32; each of the water film tubes 3 horizontally runs through the left and right side walls of the dust removal chamber 1; The left end communicates with the intake pipe 11, and the right end of the water film pipe 3 stretches into the separation chamber 2, and a shut-off valve 31 is also installed on the right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com