Sealing reaction device

A reaction device, flexible sealing technology, applied in chemical/physical/physical-chemical stationary reactors, inert gas generation, chemical/physical/physical-chemical processes, etc., can solve unfavorable reactions, poor sealing performance, and volatilization of harmful substances. and other problems, to achieve the effect of improving the speed and stability of the reaction, protecting the operator, and improving the stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

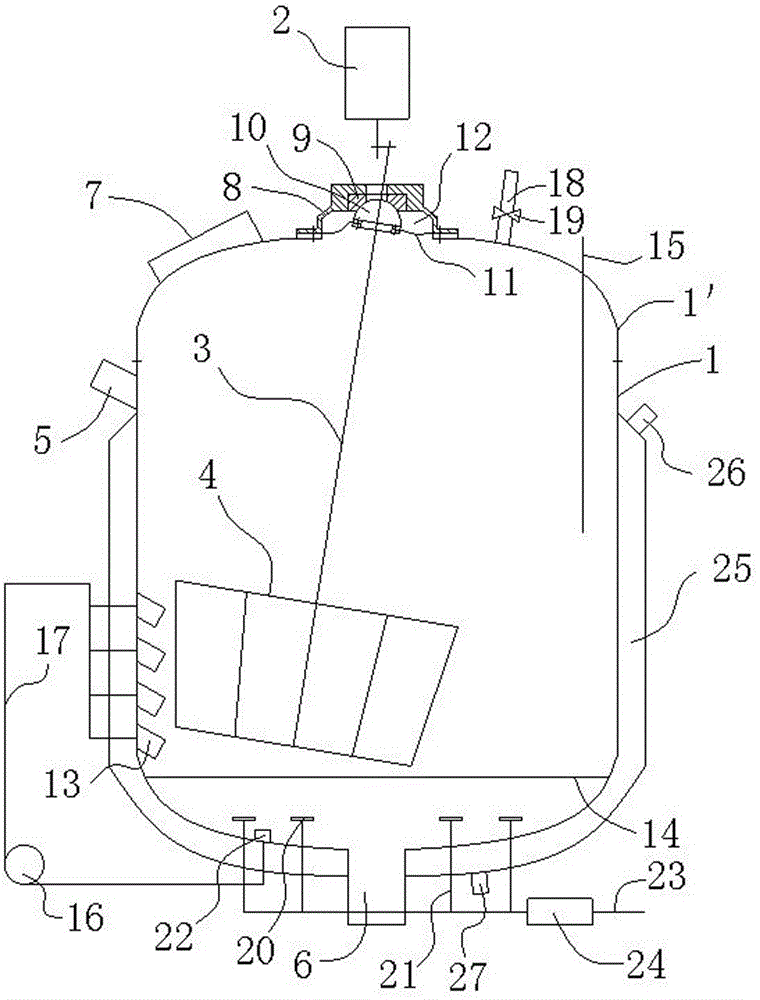

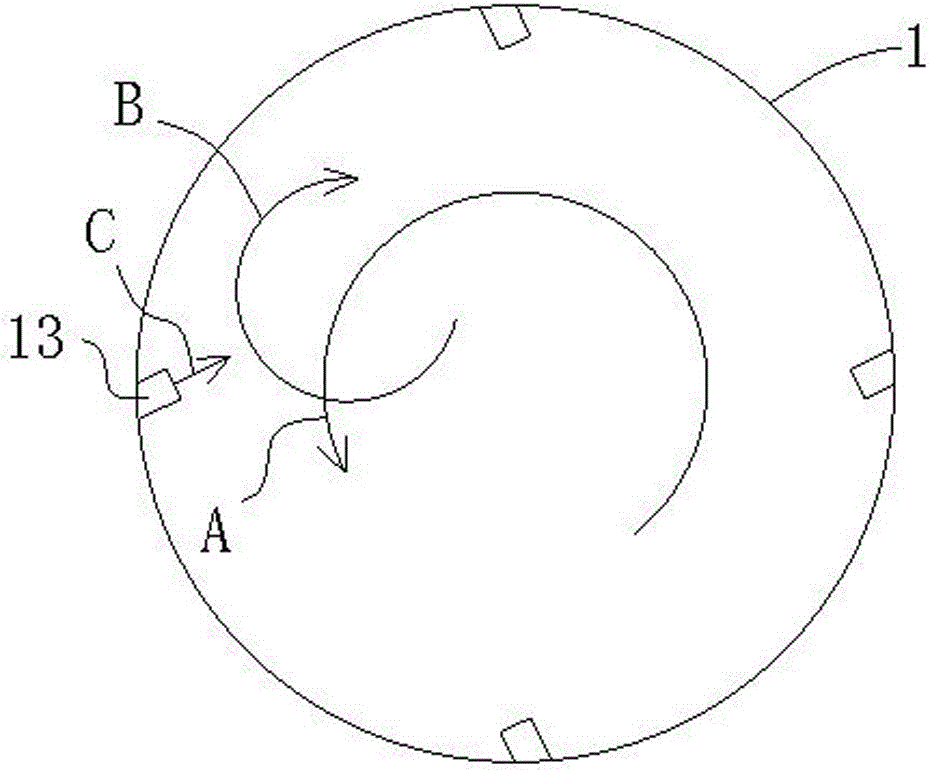

[0023] Such as figure 1 As shown, it is a sealed reaction device of the present invention, which consists of a tank body 1 and a tank cover 1' arranged above the tank body 1. The tank cover 1' is clamped at the interface of the tank body 1. Exhaust pipe 18, a pressure relief valve 19 is installed on the exhaust pipe 18, an observation port 7 and a thermometer 15 inserted into the tank body 1 are also installed on the tank cover 1', and the tank body 1 is provided with a feeding port 5 and a feeding port 6. The tank cover 1' is installed with a stirring shaft 3 that extends into the tank body 1 and is driven by a motor 2. The bottom of the stirring shaft 3 is fixed with a stirring paddle 4. A round hole is opened in the center of the tank cover 1', and a Bracket 8, a sealed spherical bearing (composed of a bearing box 9 and a sphere 10) is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com