Spiral separation type coal separation technology

A spiral separator and spiral technology, applied in the field of coal preparation, can solve the problem of low purity of clean coal tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following specific embodiments will further describe the present invention in detail.

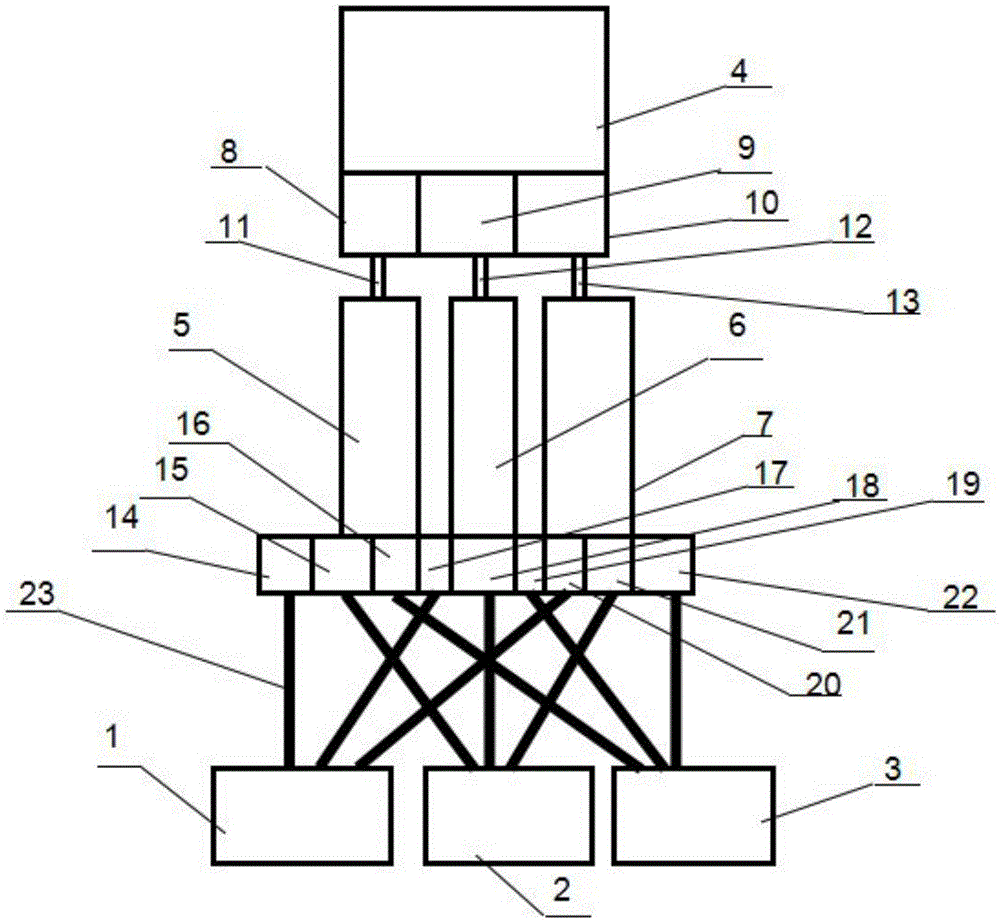

[0016] A kind of spiral separation coal preparation technology, comprising a spiral separator, also includes the first connecting groove 1, the second connecting groove 2 and the third connecting groove 3, in the present invention, the mentioned spiral separator is four Taiwan, respectively the first spiral separator 4, the second spiral separator 5, the third spiral separator 6 and the fourth spiral separator 7, wherein the second spiral separator 5, the third spiral separator The machine 6 and the fourth spiral separator 7 are arranged side by side, and the first spiral separator 4 is located at the upper end of the second spiral separator 5, the third spiral separator 6, and the fourth spiral separator 7. In the middle; at the same time, the first connecting tank 1, the second connecting tank 2 and the third connecting tank 3 are located at the bottom of the second spiral sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com