An automatic trace smearing and sealing process device that comprehensively improves the straight-through rate of tin on LEDs

A sealing device and straight-through rate technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of poor batch tin application, high workload and cost, and difficult to find, and reduce the need for manual spraying and stripping. Molding agent work, optimize work efficiency, ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

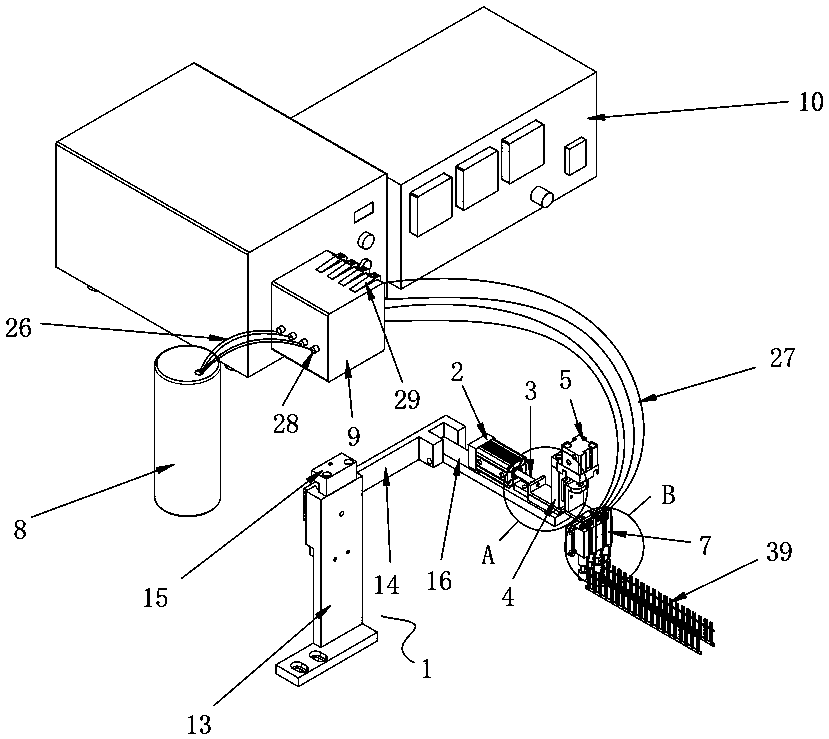

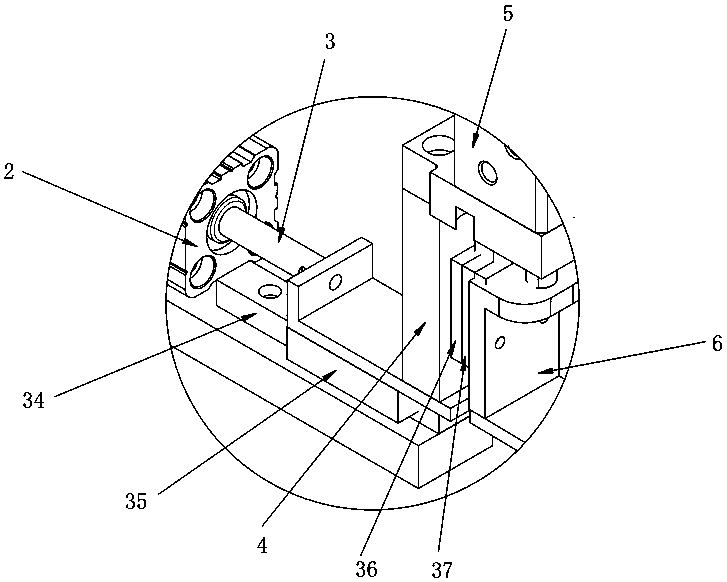

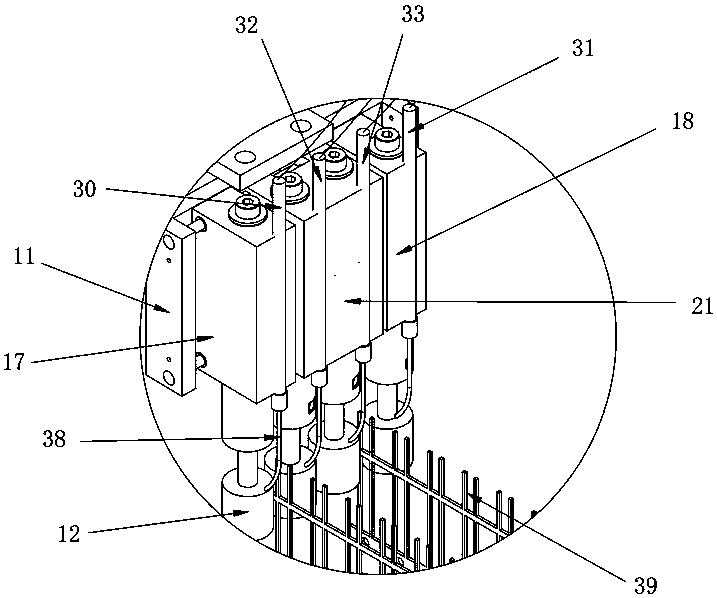

[0027] An automatic trace smearing and sealing process device described in Example 1 that comprehensively improves the pass-through rate of tin on LEDs, such as figure 1 and figure 2As shown, it includes a bracket structure 1 fixedly installed on the working table of the LED automatic sealing machine, a push cylinder 2 installed on the bracket structure, and a push rod 3 that can move in parallel to realize reciprocating motion at the output end of the push cylinder. Connected with a support frame 4, the support frame is provided with a lifting cylinder 5, the output end of the lifting cylinder is connected with an L-shaped support plate 6 capable of moving up and down, and a quantitative infusion smearing device 7 for quantitatively outputting smear liquid is installed on the L-shaped support plate The quantitative infusion application device is connected with an infusion tube; it also includes a liquid storage tank 8 for storing the smear liquid, a micro delivery pump 9 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com