Flushing device for anchor connecting steel wire rope of platform maintenance work ship

A technology for maintenance work and washing device, which is applied to the washing device of anchor connecting wire rope and the field of maintaining work boats, can solve the problems of shortening the service life of the winch drum and the anchor connecting wire rope, damage to the winch drum, frequent failures, etc., and achieves a significant cleaning effect. , the effect of prolonging the service life and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

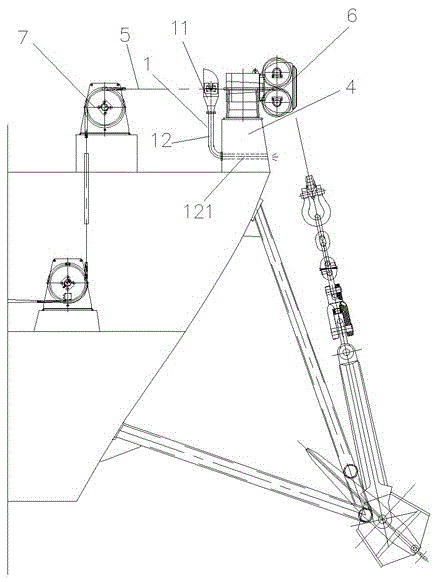

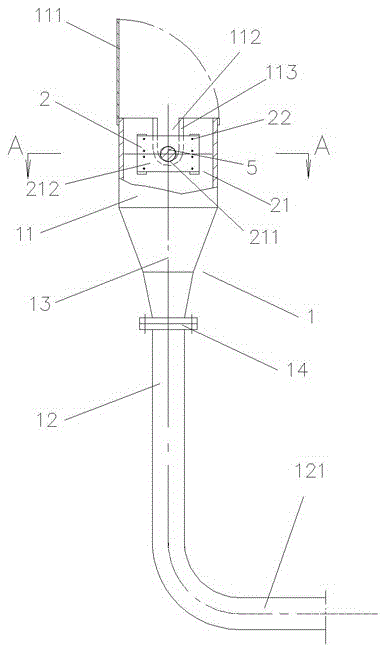

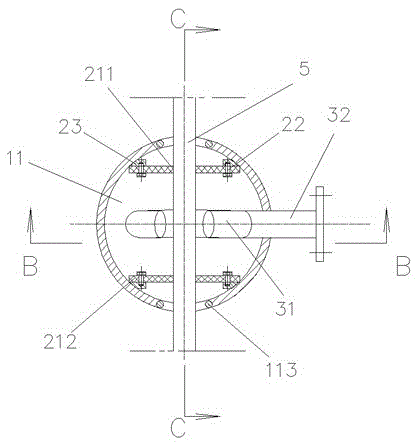

[0019] like Figure 1 to Figure 4 As shown, this embodiment includes a water collection box drainage mechanism 1, a decontamination mechanism 2 and a water spray flushing pipe 3. The water collection box drainage mechanism 1 includes an upper water collection box 11 and a lower L-shaped drain pipe 12. The water collection box 11 adopts DN250 General-purpose steel pipe is made, and one side of its upper end is hinged with water collection box cover 111 one side, closes water collection box cover 111 during flushing, can prevent that flushing water overflows and contaminates the deck. The lower end of the water collection tank 11 is welded to the reducing joint 13, the reducing joint 13 is fixedly connected to the upper end of the L-shaped drain pipe 12 through the flange 14, and the horizontal pipe 121 at the lower end of the L-shaped drain pipe 12 is welded and fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com