Protection reagent bottle-based treatment system

A technology for protecting reagents and processing systems, applied in the field of pharmaceutical equipment, can solve problems such as incomplete cleaning of reagent bottles, and achieve the effects of avoiding wear, improving structural stability, and avoiding firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

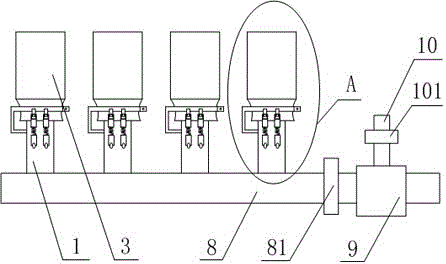

[0039] Such as Figure 1 to Figure 3 As shown, the treatment system based on the protective reagent bottle, including the water inlet system and the cleaning mechanism;

[0040] Described water inlet system comprises water inlet pipe 8, is provided with first valve 81 on water inlet pipe 8, on water inlet pipe 8

[0041] A nozzle 1 is provided, and the nozzle of the nozzle 1 is set upward;

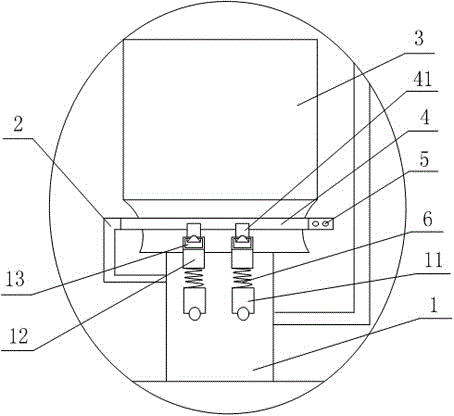

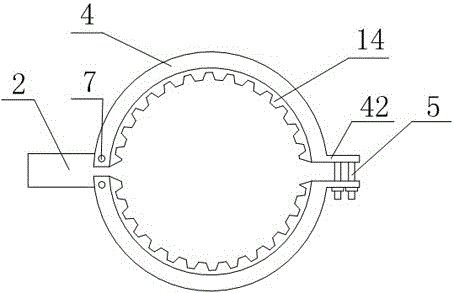

[0042] The cleaning mechanism includes a nozzle 1, the outer wall of the nozzle 1 is provided with a fixed frame 2, and the fixed frame 2 is symmetrically connected with two arc-shaped plates 4, the arc-shaped plates 4 cooperate with the outer wall of the bottle mouth of the reagent bottle 3, and the arc-shaped plates 4. One end is connected with the fixed frame 2 through the rotating shaft 7, and the other end is provided with a protrusion 42, wherein one protrusion 42 is provided with a threaded hole, and the other protrusion 42 is provided with a threaded through hole matching the thre...

Embodiment 2

[0044] Such as Figure 1 to Figure 3 As shown, this embodiment is based on Embodiment 1, and the fixing frame 2 is a U-shaped fixing frame, one end of which is connected to the outer wall of the nozzle 1, and the other end is connected to the arc plate 4; the outer wall of the nozzle 1 is hinged with 4 A fixed rod 11, the non-hinged end of the fixed rod 11 is connected with a spring 6, the non-connected end of the spring 6 is connected with a connecting rod 12, and the non-connected end of the connecting rod 12 is provided with a fixed buckle 13, and the outer wall of the arc plate 4 There is a hook 41 that cooperates with the fixed buckle 13; the fixed buckle 13 is square; it can also be round or oval; the fixed frame 2 and the arc-shaped plate 4 are made of hard aluminum alloy; The water inlet end of the water pipe 8 is provided with a mixing tank 9, the mixing tank 9 is connected with a liquid feeding pipe 10, and the liquid feeding pipe is provided with a second valve 101;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com