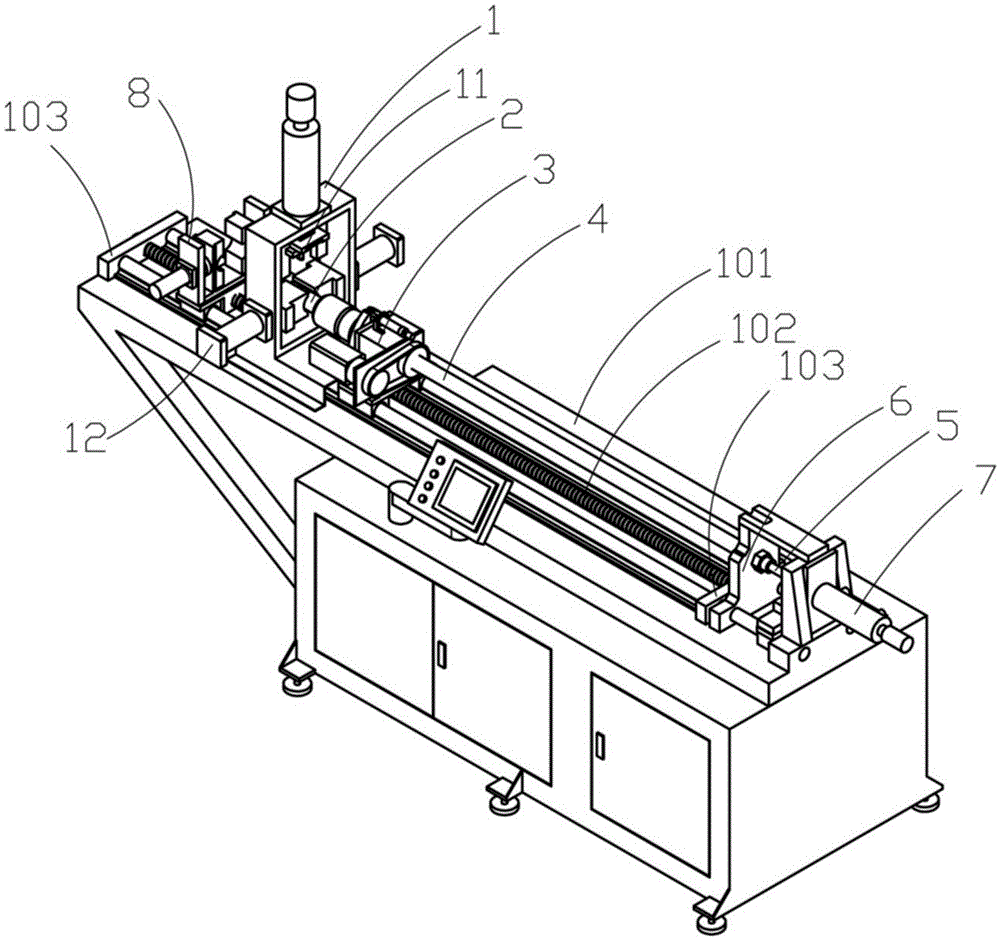

Punching and flanging machine

A flanging machine and punching technology, which is applied in the field of punching and flanging machines, can solve problems such as low processing efficiency, complex molds, and easy wear of the cutter head, and achieve the effect of reducing labor intensity and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: refer again Figure 8 , the above-mentioned groove 241 is arranged along the length direction of the above-mentioned frame 101 to be low at the front and high at the back. When this embodiment is working: the pipe fittings are fed in from the 8 ends of the front feeding cart, the pipe fittings are inserted into the mold core 2, and pass through the punching mechanism 1 to the rear positioning block of the rear feeding cart 3, and the rear feeding cart 3 clamps the pipe fittings and goes Pull the rear end of the frame 101 until the rear feeding vehicle 3 reaches the end of the above-mentioned frame 101, the front feeding vehicle 8 clamps the pipe fittings, the rear feeding vehicle 3 releases the pipe fittings and moves to the front end of the above-mentioned frame 101, and the rear feeding vehicle 3 clamps For pipe fittings, the front feeding truck 8 releases the pipe fittings, and the rear feeding truck 3 pulls the pipe fittings toward the rear end of the ...

Embodiment 2

[0040] Embodiment 2: Refer again Figure 9 , the above-mentioned groove 241 is arranged along the length direction of the above-mentioned frame 101 with the front high and the rear low. Harder pipe fittings, with the mode of pulling, taper tongue rod connecting rod 5 is difficult for deformation. When this embodiment is working: the pipe fittings are fed in from the 8 ends of the front feeding cart, the pipe fittings are inserted into the mold core 2, and pass through the punching mechanism 1 to the rear positioning block of the rear feeding cart 3, and the rear feeding cart 3 clamps the pipe fittings and goes Pull the rear end of the frame 101 until the rear feeding vehicle 3 reaches the end of the above-mentioned frame 101, the front feeding vehicle 8 clamps the pipe fittings, the rear feeding vehicle 3 releases the pipe fittings and moves to the front end of the above-mentioned frame 101, and the rear feeding vehicle 3 clamps For pipe fittings, the front feeding truck 8 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com