Water-cooled quick-condensation control method for deep and shallow distribution of hard abrasives in magnetic abrasive metal matrix

A technology of magnetic abrasives and hard abrasives, which is applied in the field of water-cooled quick-setting control, can solve problems such as low grinding performance, low life of magnetic abrasives, and poor metal cutting ability, so as to improve magnetic permeability and grinding ability, reduce overall height, The effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

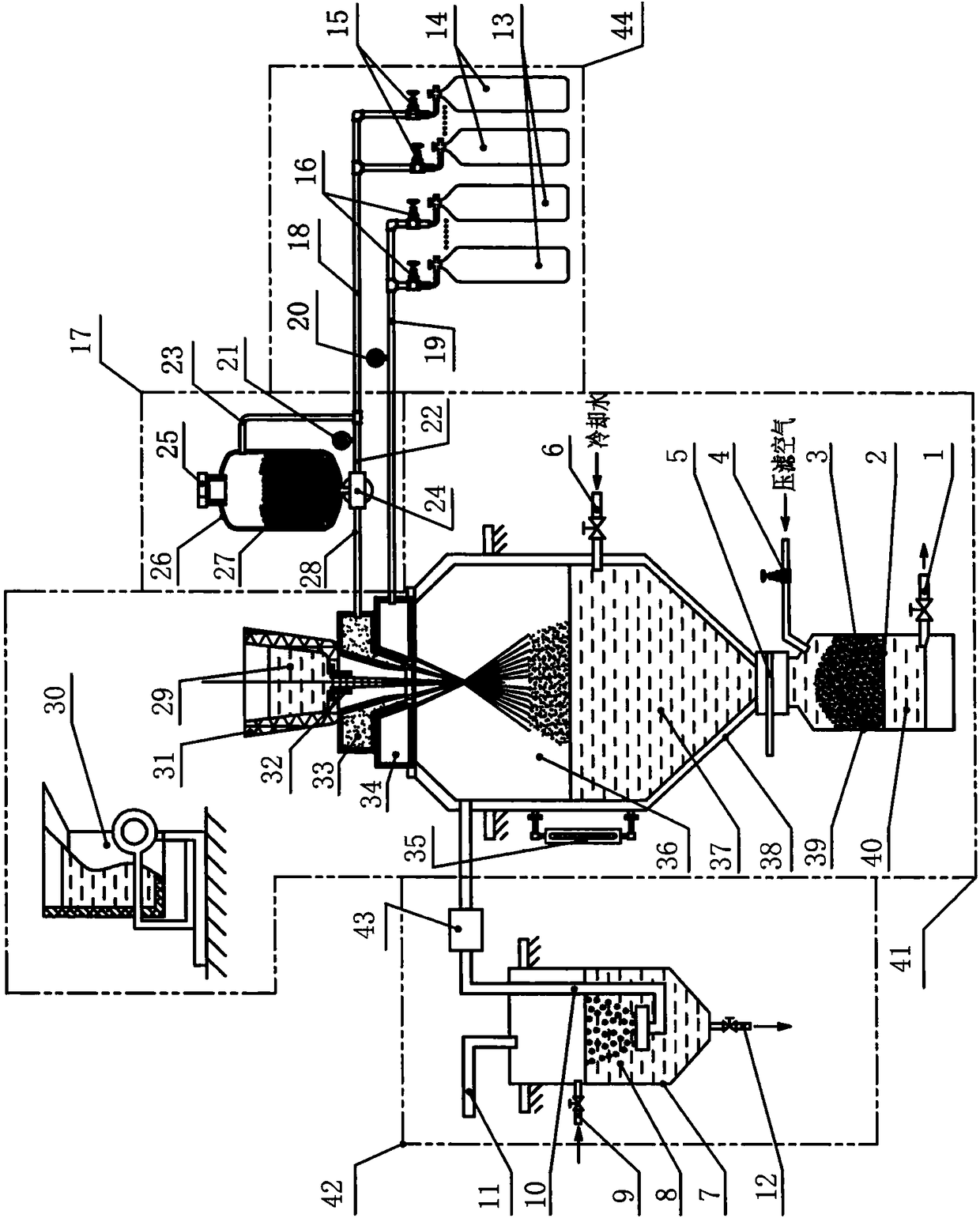

[0013] The preparation of magnetic abrasive adopts the following steps:

[0014] 1. Experimental optimization of cooling water level parameters: determine the process parameters such as metal matrix material, atomizing gas nozzle atomization pressure, molten metal superheat, molten metal flow, powder mixing gas nozzle pressure, hard abrasive flow, hard abrasive material, etc. Fill the lower part of the atomization cooling chamber of the mixed powder gas atomization fast-setting magnetic abrasive preparation equipment with circulating cooling water, adjust the water level of the cooling water to be 5m away from the gas atomization nozzle, and do the first magnetic abrasive preparation experiment to prepare about 2Kg of magnetic abrasive Afterwards, adjust the height of the cooling water level and carry out multiple experiments, and prepare about 2Kg of magnetic abrasives for every 100mm increase in the cooling water level, and stop the experiment when the cooling water level exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com