SCARA robot joint zero returning control method

A technology of robot joints and robots, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., to improve positioning accuracy and avoid collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

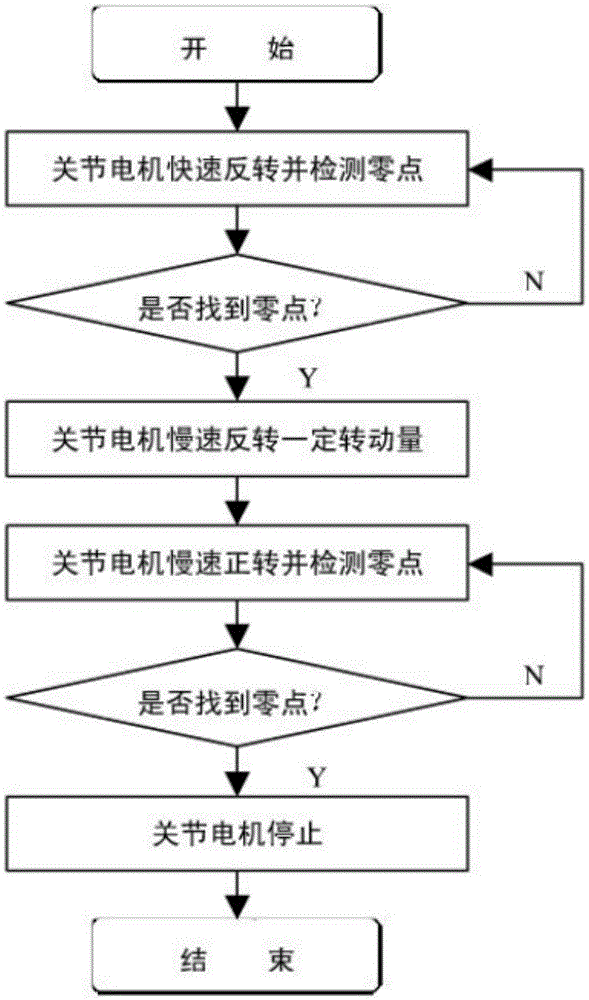

[0018] Such as figure 1 As shown, the present invention provides a kind of SCARA robot joint zero return control method, and it comprises the following steps:

[0019] (1) The joint motor reverses and detects the zero point;

[0020] (2) When the zero position is detected, the joint motor continues to reverse;

[0021] (3) The joint motor rotates forward and detects the zero point;

[0022] (4) When the zero position is detected, the joint motor stops running, and the zero return process is completed.

[0023] Specifically, according to the control function requirements of the system, the SCAR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com