Under-actuated mechanical arm wrist based on gear transmission

A gear transmission and under-actuation technology, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems that the manipulator does not have multiple power outputs and cannot meet the environmental requirements of nuclear power plants, so as to avoid mutual interference and facilitate centralized protection and work The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

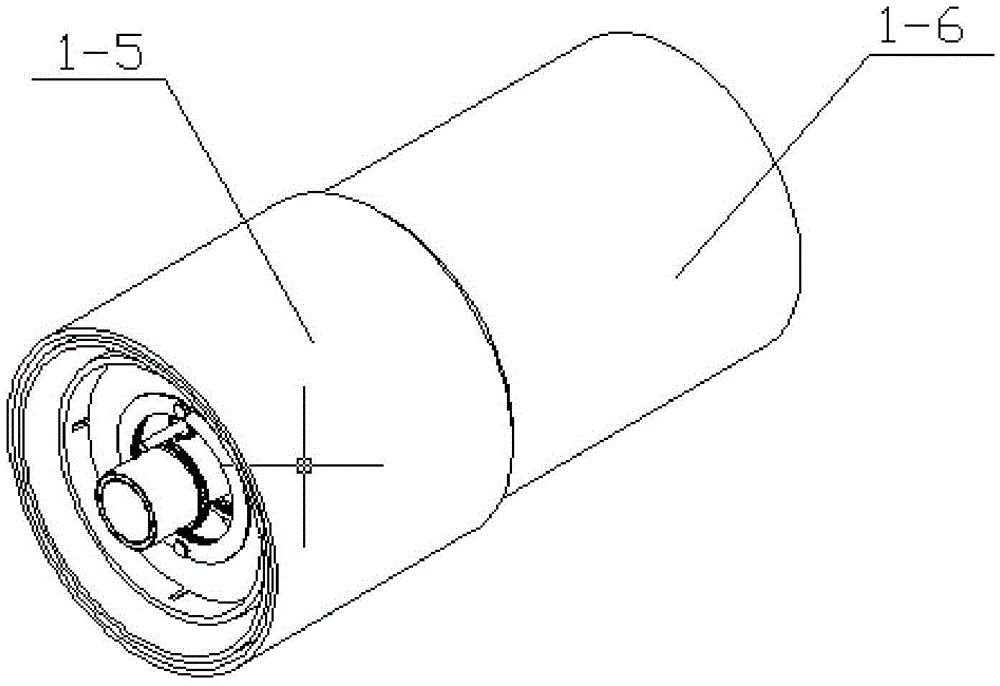

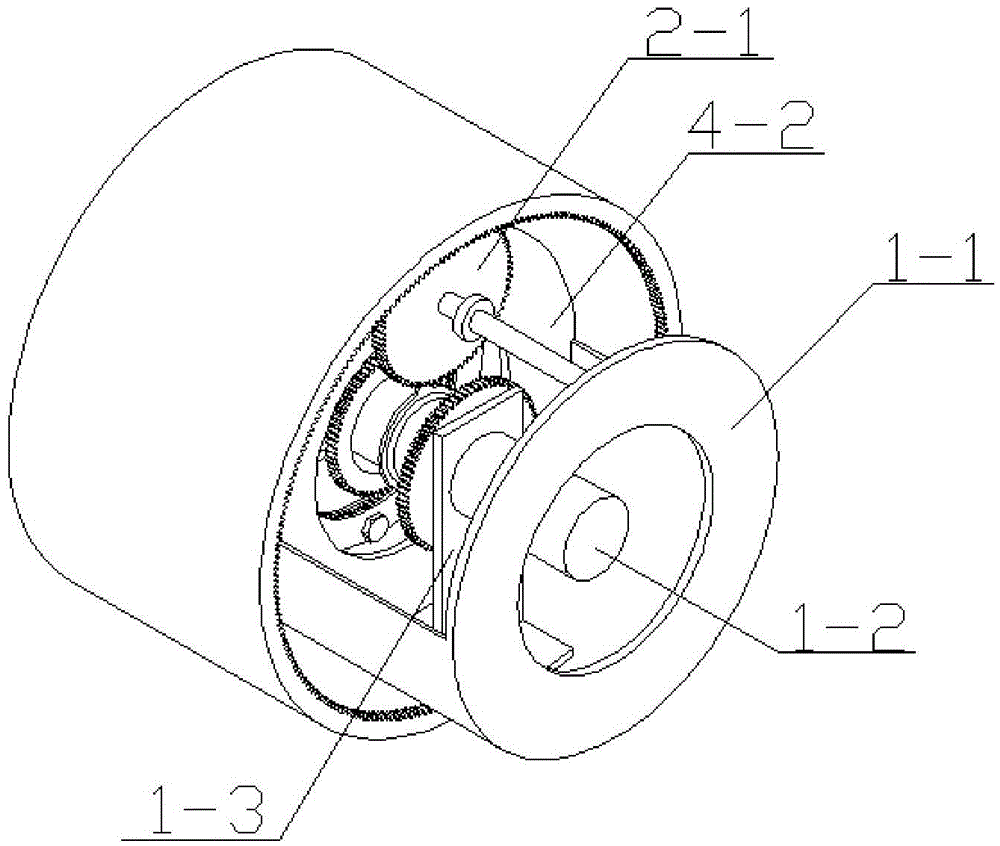

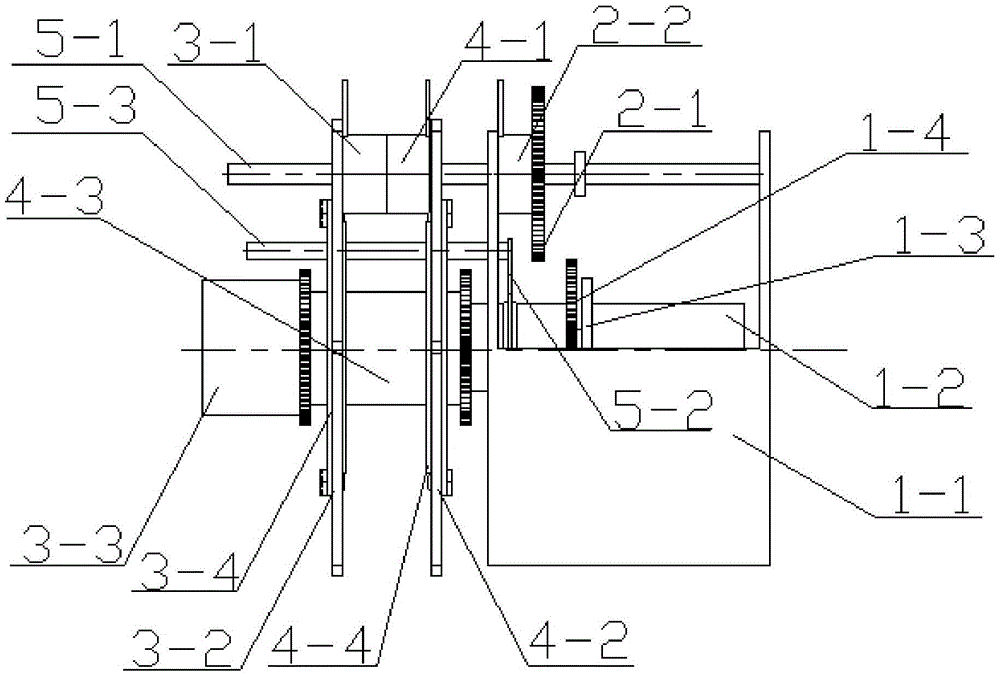

[0015] Specific implementation mode one: combine Figure 1-Figure 6 To illustrate this embodiment, an underactuated mechanical arm wrist based on gear transmission in this embodiment includes a wrist body and a mechanical structure shell 1-5, the mechanical structure shell 1-5 is set on the wrist body, and the wrist body includes a fixed end 1-5 1. Motor 1-2, motor support 1-3, input gear end 1-4, support shaft 5-1, outer layer transmission gear 2-1, outer layer clutch 2-2, shaft passing rod 5-2, Wheel shaft 5-3, inner wheel 3-5, middle wheel 4-5, two-way clutch left end 3-1, two inner baffles 3-4, inner ring gear 3-2, inner output End 3-3, two-way clutch right end 4-1, middle-level ring gear 4-2, middle-level output end 4-3 and two middle-level baffle plates 4-4,

[0016] The motor support 1-3 is fixedly installed on the fixed end 1-1, the motor 1-2 is installed on the motor support 1-3, the support shaft 5-1 is parallel to the output end of the motor 1-2 and fixedly install...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Image 6 Describe this embodiment, the fixed end 1-1 of this embodiment includes a first ring body 1-1-1, a second ring body 1-1-2 and a connecting body 1-1-3, the first ring body 1-1 -1 and the second annular body 1-1-2 are arranged side by side, and the outer edge of the first annular body 1-1-1 and the outer edge of the second annular body 1-1-2 pass through the connecting body 1-1- 3 connections. With such a setting, the movement is more flexible. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 2-Figure 3 Describe this embodiment, the mechanical structure housing 1-5 of this embodiment is a housing with internal teeth on the inner side wall. So set, the movement is flexible. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0021] combine image 3 with Figure 4 Explain that this embodiment includes a mechanical structure shell 1-5 and a connected mechanical arm 1-6. The working principle of the outer layer is: the motor 1-2 drives the input end 1-4 to move, and a fixed gear is welded on the input end 1-4. , the normal state is idling, under the action of the clutch 2-2, the gear 2-1 is moved, so that the gear 2-1 meshes with the input end 1-4, and drives the outer layer output end 2-3 to move. The independent work of the outer layer output end is realized, and the stop work of the inner layer output end and the middle output end is realized.

[0022] combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com