a sawing machine

A sawing machine and sawing disc technology, applied in the field of sawing machines, can solve the problems of inability to guarantee the dimensional accuracy of wood, low cutting efficiency, and inability to ensure that the wood board does not move, and achieve the effects of improving cutting efficiency, dimensional accuracy and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

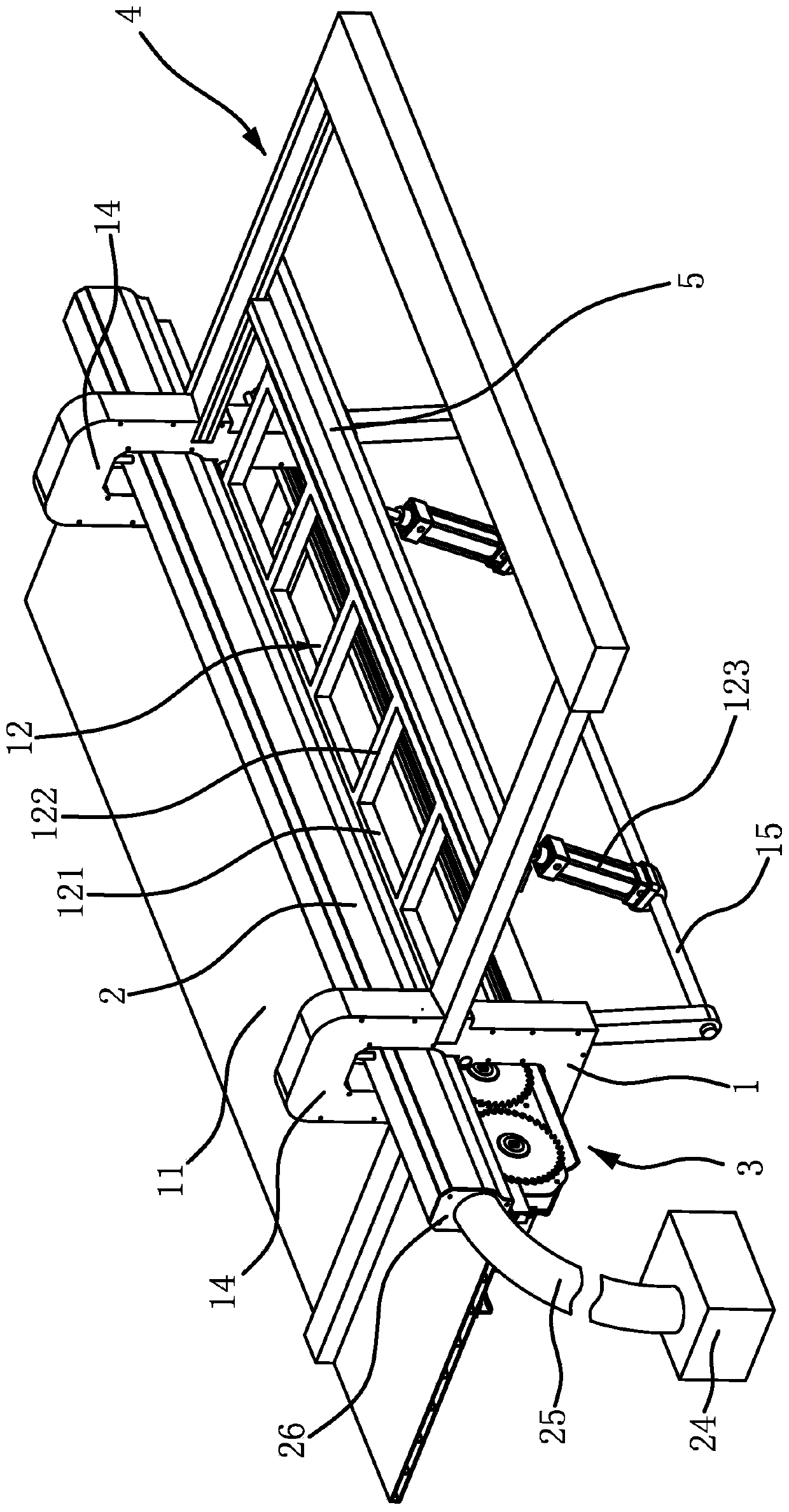

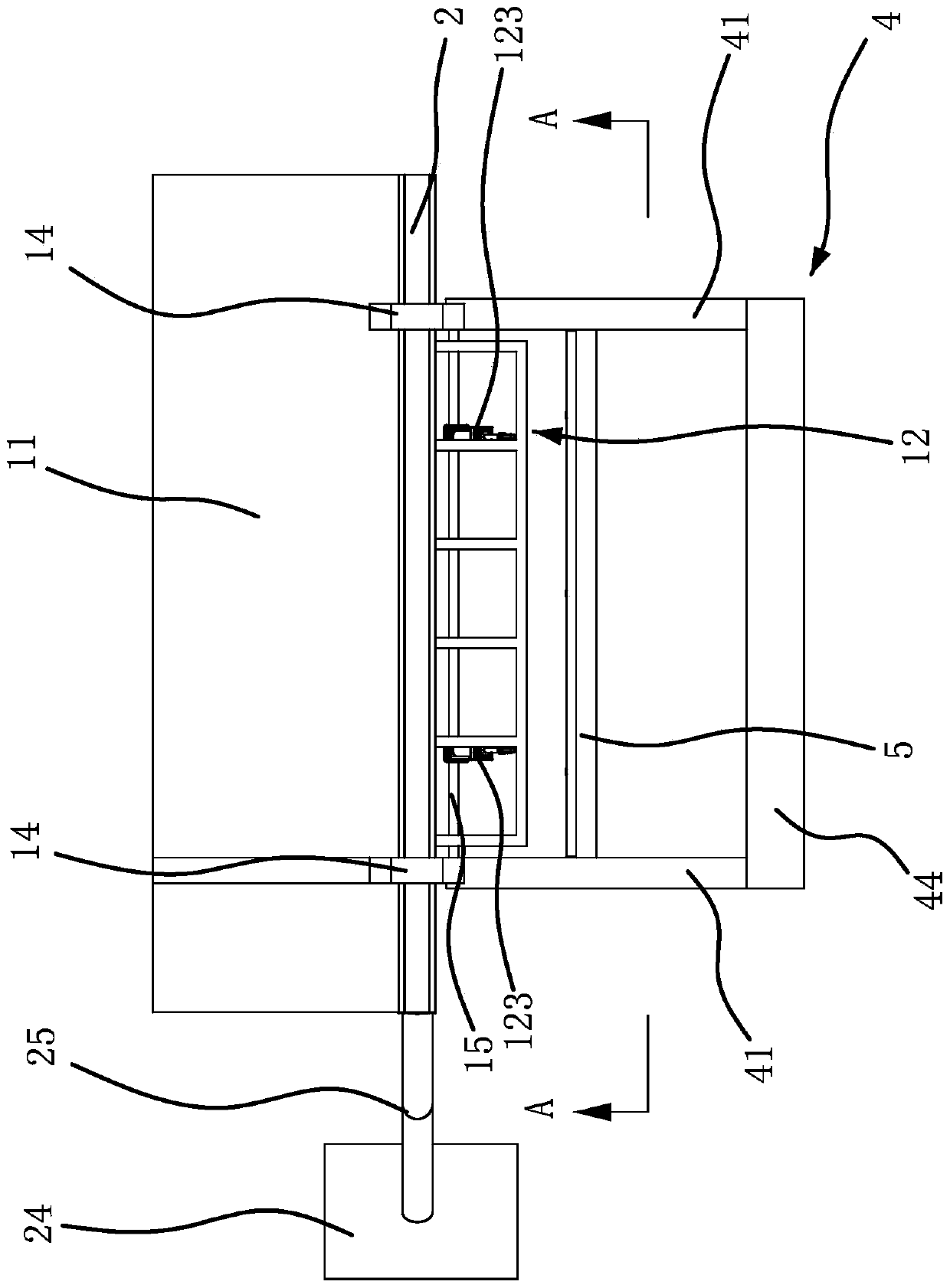

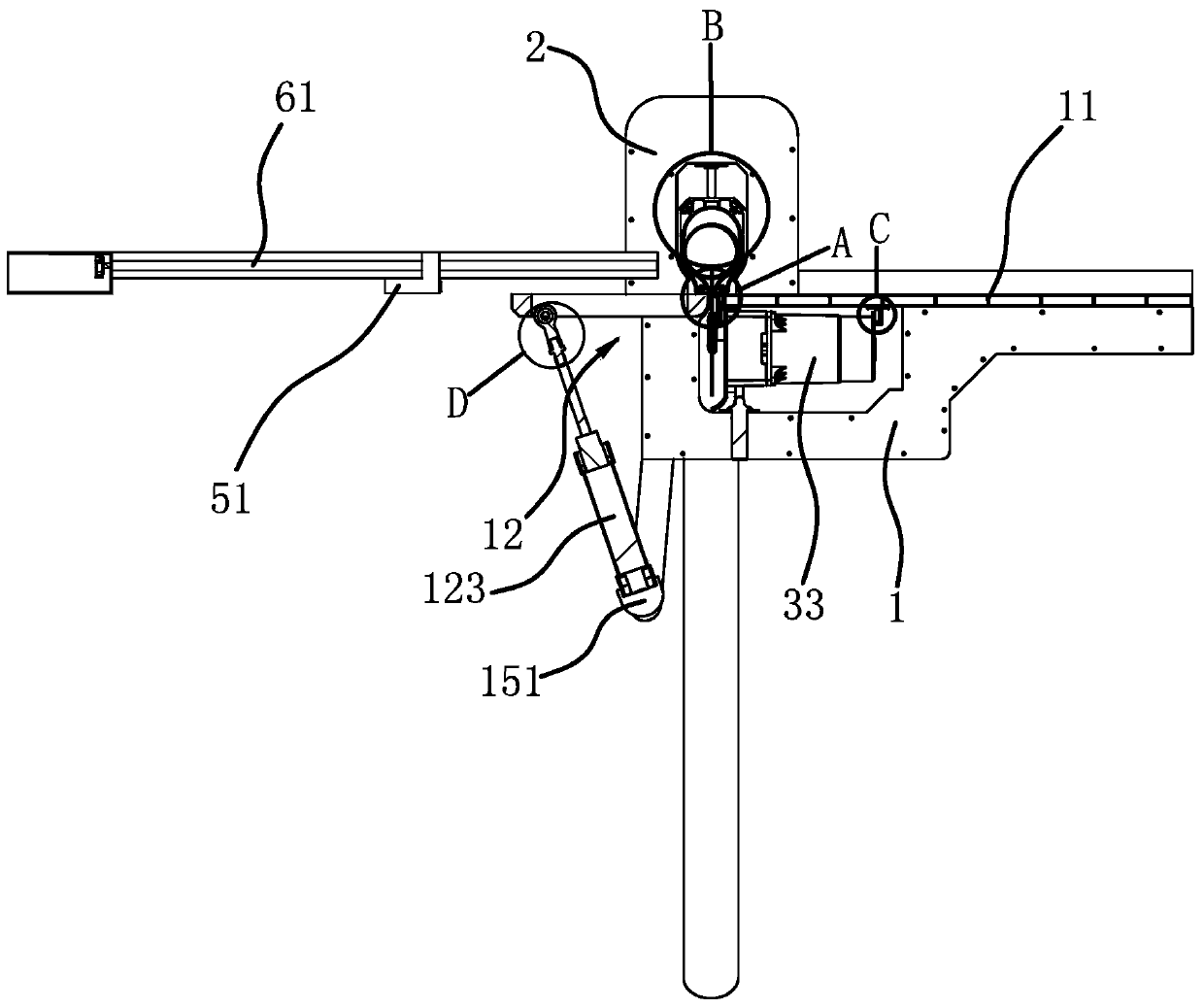

[0044] Such as figure 1 , figure 2 , image 3 and Figure 12 As shown, the sawing machine includes a frame 1, a worktable 11 and a saw head 3. The worktable 11 is horizontally fixed on the frame 1, and the frame 1 is also oscillatingly connected with a blanking frame 12, and the blanking frame 12 swings upwards. When reaching the maximum angle position, the upper side of the blanking rack 12 is flush with the upper surface of the workbench 11, and the blanking rack 12 and the workbench 11 all have straight edges, and the straight edge of the blanking rack 12 and the edge of the workbench 11 The straight edges face each other and form an avoidance gap 13 . The saw head 3 is arranged on the lower surface of the workbench 11 and the saw head 3 can slide along the length direction of the avoidance gap 13 .

[0045] Such as Figure 4 to Figure 6 As shown, the saw head 3 includes a mounting frame 31 and two saw discs 32 that are positioned on the same plane and have gaps. The m...

Embodiment 2

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the drive structure includes a drive motor and a transmission gearbox fixed on the mounting frame. The motor shaft passes through the transmission gearbox and is connected to one of the saw discs. The transmission teeth are fixed on a section of the motor shaft of the drive motor located in the transmission gearbox. The driven gear is connected to the transmission gearbox through the rotation of the shaft. The driven teeth and The transmission teeth are meshed, and one end of the rotating shaft passes through the transmission gear box and is connected with another saw disc.

Embodiment 3

[0060] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference lies in that the plate feeding stroke control device includes a stroke control cylinder, the cylinder body of the stroke control cylinder is fixed on the bracket, and the piston rod end of the stroke control cylinder is connected to the The bar is fixed. The position of the stop rod relative to the worktable is controlled by controlling the stretching amount of the piston rod of the stroke control cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com