Garbage classifier

A garbage sorting and sorting machine technology, applied in garbage collection, sorting, conveyor objects, etc., can solve the problems of endangering human health, garbage sorting machine does not have a cleaning system, cross-contamination of various garbage, etc., to avoid cross-contamination , maintain a good medical environment, easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

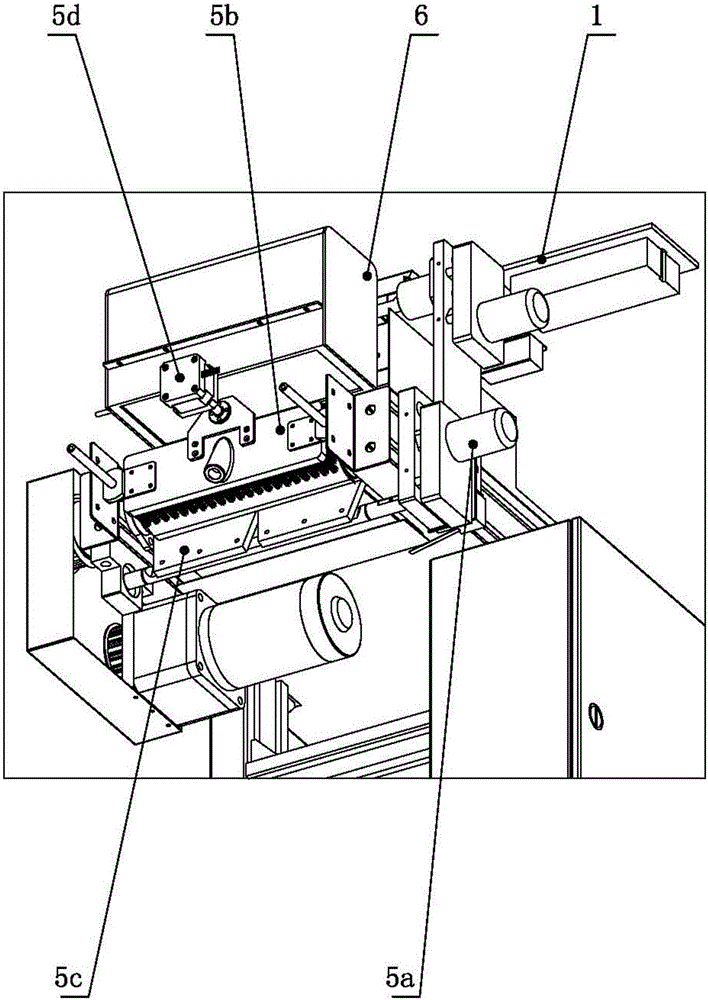

[0030] Such as image 3 As shown, the cleaning system 5 includes a cleaning liquid supply system 7, a cleaning brush 5b, a wiper 5c, and a cleaning chamber for collecting waste cleaning liquid. The cleaning brush 5b and the wiper 5c are all arranged in the cleaning chamber, and the cleaning chamber It is connected with the garbage conveying system and is used to receive waste water, and at the same time, a sewer pipe is set at the bottom. Cleaning brush 5b, wiper blade 5c are respectively driven by respective drive mechanism ( image 3 Middle: 5a is the driving mechanism of the wiper; 5d is the driving mechanism of the cleaning brush) to control approaching or moving away from the garbage conveying system, specifically the garbage conveying belt 3b approaching or away from the garbage conveying system.

[0031] When cleaning, make the garbage conveyor belt 3b run in reverse, control the cleaning brush 5b to be close to the garbage conveyor belt 3b, make the bristles fit the g...

Embodiment 2

[0033] The difference from the cleaning system 5 described in Embodiment 1 is that the cleaning brush 5b and the wiper blade 5c are connected by a connecting rod 5e, and the driving mechanism 5d controls one of the parts to approach or stay away from the garbage conveyor belt 3b, and is driven by the connecting rod 5e It can control the synchronous action of another component. The specific structure is: the cleaning system 5 includes a cleaning liquid supply system 7, a cleaning brush 5b, a wiper blade 5c and a cleaning chamber for collecting waste cleaning liquid, and the cleaning brush 5b and the wiper blade 5c are all arranged in the cleaning chamber. The warehouse is connected with the garbage conveying system. Cleaning system 5 also includes connecting rod 5e, cleaning brush 5b and wiper blade 5c are respectively rotatably connected to the two ends of connecting rod 5e, as Figure 4 As shown, a cleaning brush drive mechanism 5d is provided on the cleaning brush 5b, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com