Height-adjustable corner transport rack

An adjustable and corner-adjustable technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of large occupied space, resources, capital consumption, and long conveyor belt length, so as to save space, expand the application area, and set up simply. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

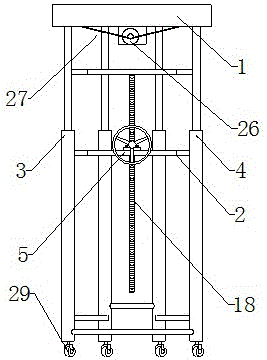

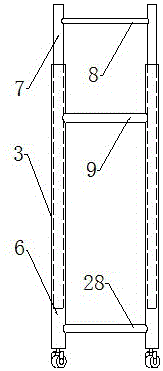

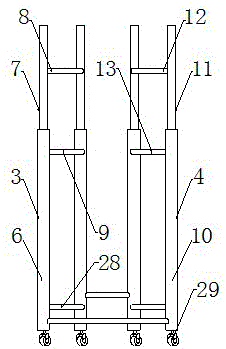

[0027] Such as figure 1 As shown in -7, a height-adjustable corner transfer frame includes a corner transfer mechanism 1 and a lifting mechanism 2, and the corner transfer mechanism 1 is arranged on the top of the lifting mechanism 2, and the lifting mechanism 2 is composed of The lifting frame A3, the lifting frame B4 and the adjustment mechanism 5 arranged between the lifting frame A3 and the lifting frame B4 are composed of two sleeves A6 arranged on the left and right sides and two sleeves arranged on the two sleeves. A6 consists of two elevating rods A7, an auxiliary support rod A8 is horizontally arranged on the upper part between the two elevating rods A7, and a bearing is arranged horizontally on the upper part of the two sleeves A6. Rod A9; the lifting frame B4 is composed of two sleeves B10 arranged on the left and right sides and two lifting rods B11 arranged in the two sleeves B10, and the two lifting rods B11 are separated by their An auxiliary support rod B12 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com