A method for preparing methyl formate and co-producing dimethyl ether

A technology of methyl formate and dimethyl ether, which is applied in the field of preparation of methyl formate, can solve problems such as difficulty in forming scale effect, unfavorable use by small and medium-sized enterprises, pollution, etc., and achieves not easy to oxidize and deactivate, prolong single-pass life, and atom economy sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

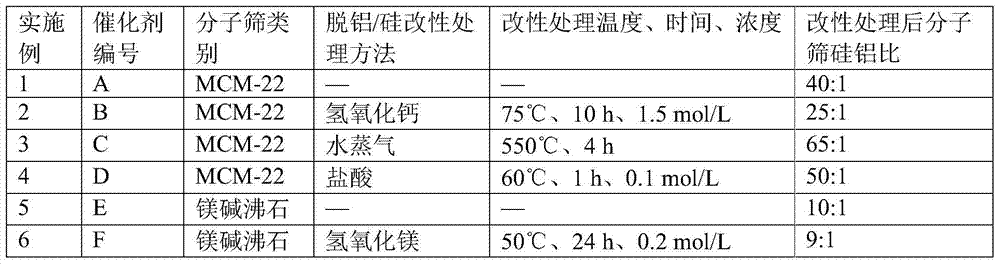

[0048] 50 g of MCM-22 molecular sieve with a sodium-type silicon-aluminum ratio of 40:1 was converted into a hydrogen-type MCM-22 molecular sieve using a standard operating procedure, which was recorded as catalyst A, as shown in Table 1.

Embodiment 2

[0050] Add 100g of MCM-22 molecular sieve with a sodium-type silicon-aluminum ratio of 40:1 to 500ml of calcium hydroxide solution with a concentration of 1.5mol / L, stir and react at 75°C for 10h, and filter the cake with 0.08ml / L The nitric acid solution was washed until the pH was 6, filtered and washed repeatedly with deionized water until neutral, dried at 100°C and converted into a hydrogen-type molecular sieve through standard operating procedures, which was recorded as Catalyst B, see Table 1.

Embodiment 3

[0052] 100g of MCM-22 molecular sieve with a sodium-type silicon-aluminum ratio of 40:1 was treated with steam at 550°C for 4 hours, and then converted into a hydrogen-type molecular sieve using standard operating procedures, which was designated as catalyst C, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com