Converter dust remover adjustment method and control system

A dust removal device and converter dust removal technology, applied in the field of converter dust removal, can solve the problems of inability to dynamically adjust the dust removal effect of the dust removal device, low adjustment accuracy, poor timeliness, etc., and achieve the effect of convenient later query, wide application range, and small changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

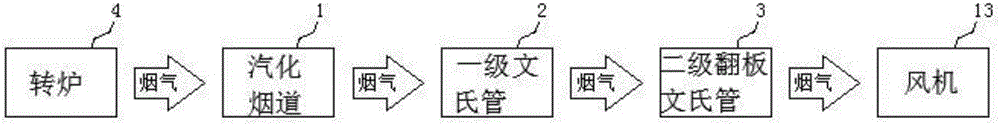

[0059] Such as Figure 10 As shown, this embodiment is an old OG dust removal device that can be automatically adjusted, including a vaporization flue 1, a first-stage venturi tube 2, a second-stage flap venturi tube 3, an online monitoring device 10, a control unit 11, and a human-computer interaction The equipment 12 and fan 13 , the flue gas discharged from the converter 4 passes through the vaporization flue 1 , the first-stage venturi tube 2 , the second-stage flap venturi tube 3 and the fan 13 in sequence.

[0060] A water supply device is designed inside the first-stage venturi tube 2 and the second-stage flap venturi tube 3, and a valve is arranged in the water supply device to control the water supply volume. The furnace mouth of the converter 4 is provided with a pressure sensor for measuring the micro pressure difference at the furnace mouth, and the fan adjusts the speed according to the micro pressure difference measured by the pressure sensor to change the flue g...

Embodiment 2

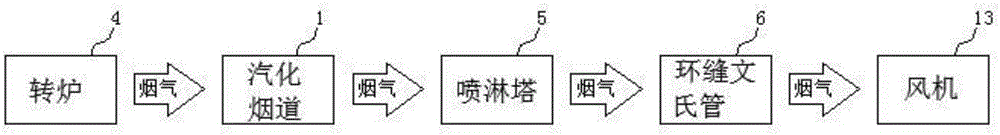

[0065] Such as Figure 11 As shown, this embodiment is a new OG dust removal device that can be automatically adjusted, including a vaporization flue 1, a spray tower 5, an annular venturi tube 6, an online monitoring device 10, a control unit 11, a human-computer interaction device 12 and a fan 13. The flue gas discharged from the converter 4 passes through the vaporization flue 1, the spray tower 5, the annular venturi tube 6 and the fan 13 in sequence.

[0066] A water supply device is designed in the spray tower 5 and the annular venturi tube 6, and a valve is arranged in the water supply device to control the water supply volume. The furnace mouth of the converter 4 is provided with a pressure sensor for measuring the micro pressure difference at the furnace mouth, and the fan adjusts the speed according to the micro pressure difference measured by the pressure sensor to change the flue gas flow velocity in the dust removal device. The opening degree of the annular seam ...

Embodiment 3

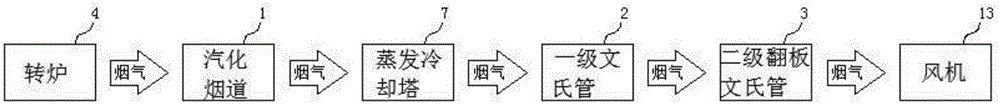

[0071] Such as Figure 12As shown, this embodiment is an old OG semi-dry dust removal device that can be automatically adjusted. The dust removal device of this embodiment is basically the same as that of Embodiment 1, except that an evaporative cooling tower 7 is added between the vaporization flue 1 and the primary venturi tube 2 . The adjustment method and control system of the dust removal device in this embodiment are consistent with those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com