Monitorable nonmetal supporting member inflaming retarding and corrosion prevention system

A support member, non-metal technology, applied in the field of flame retardant and anti-corrosion system, can solve the problems of groundwater source and atmospheric environment hazards, complicated construction, affecting structural strength and safety, etc., and achieve excellent flame retardant and heat insulation effect, fire resistance performance. The effect of superior, long-lasting washout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

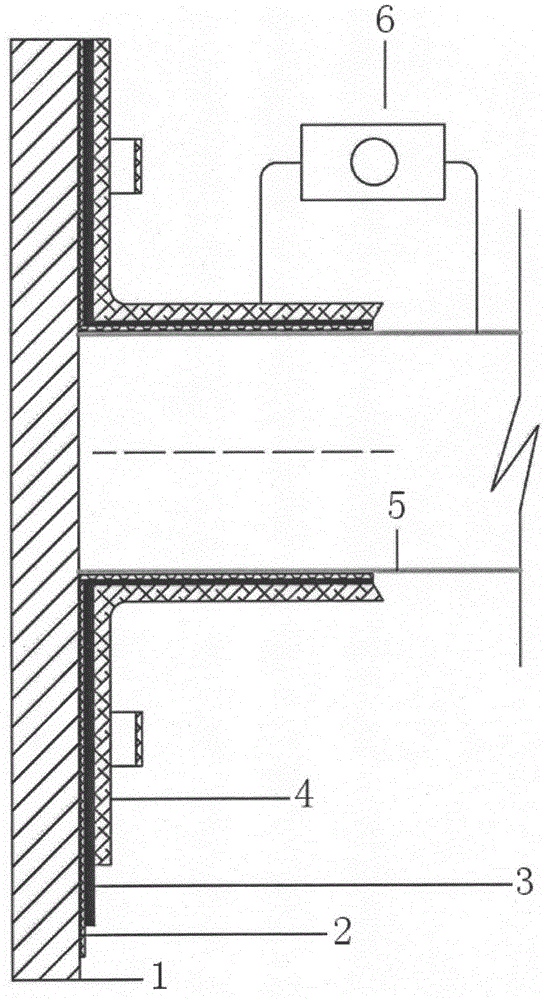

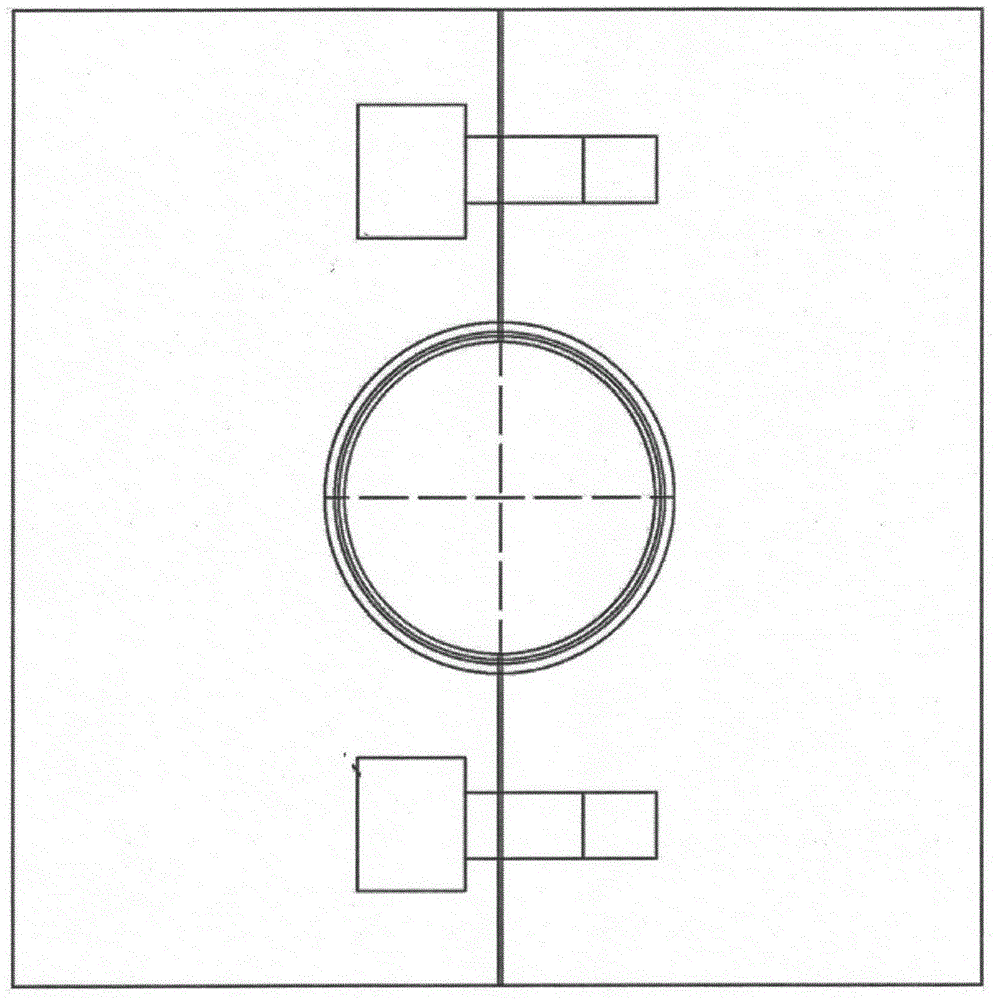

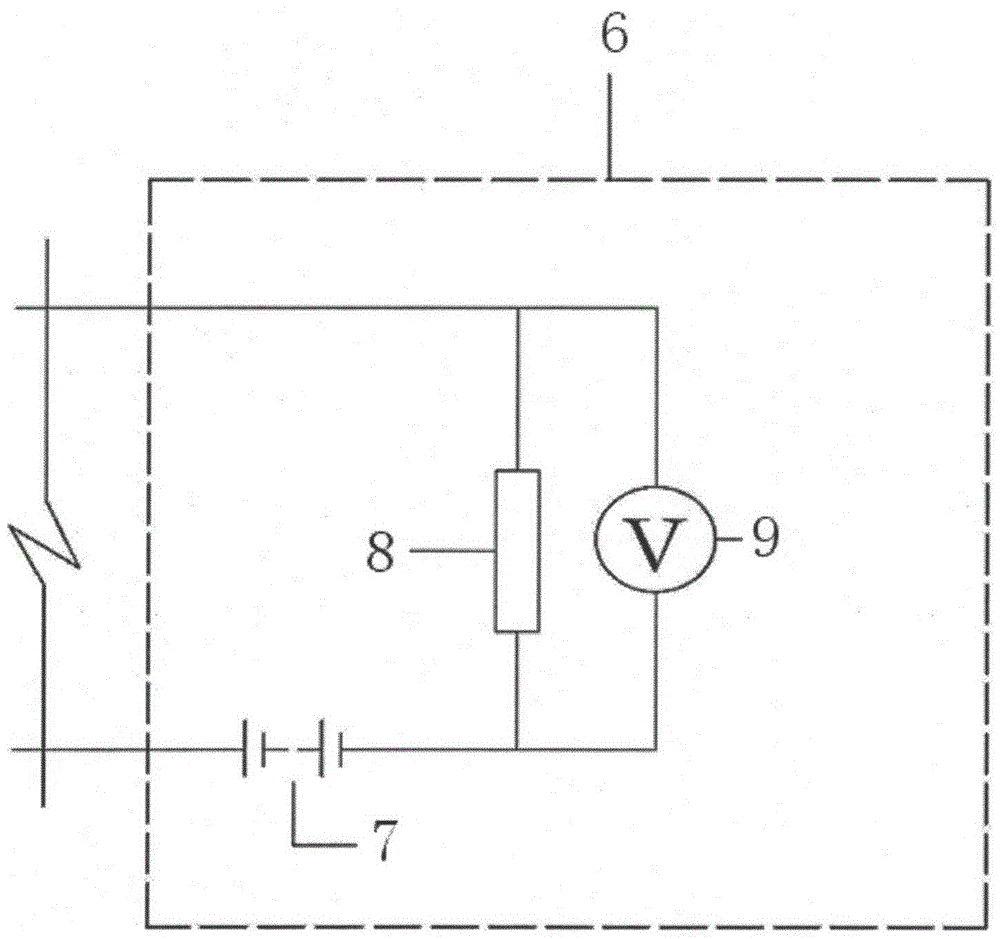

[0019] like figure 1 As shown, the present invention provides a monitorable non-metallic supporting member flame retardant and anti-corrosion system, including a base 1 and a column 5 connected to the base 1, two symmetrically arranged non-metallic supporting prefabricated members 4 buckles Closed on the column 5, each non-metal supporting prefabricated component 4 extends to the substrate 1, and a primer layer 2 and an adhesive anti-corrosion layer 3 are provided between the non-metallic supporting prefabricated component 4 and the column 5 or the substrate 1, wherein , the primer layer 2 is coated on the column 5 or the substrate 1, the two sides of the adhesive anti-corrosion layer 3 are respectively provided with a primer layer 2 and a non-metallic supporting prefabricated component 4, and the non-metallic supporting prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com