Clothes treating apparatus with a heat pump cycle

A clothing treatment device, heat pump cycle technology, applied in washing devices, washing machines with containers, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

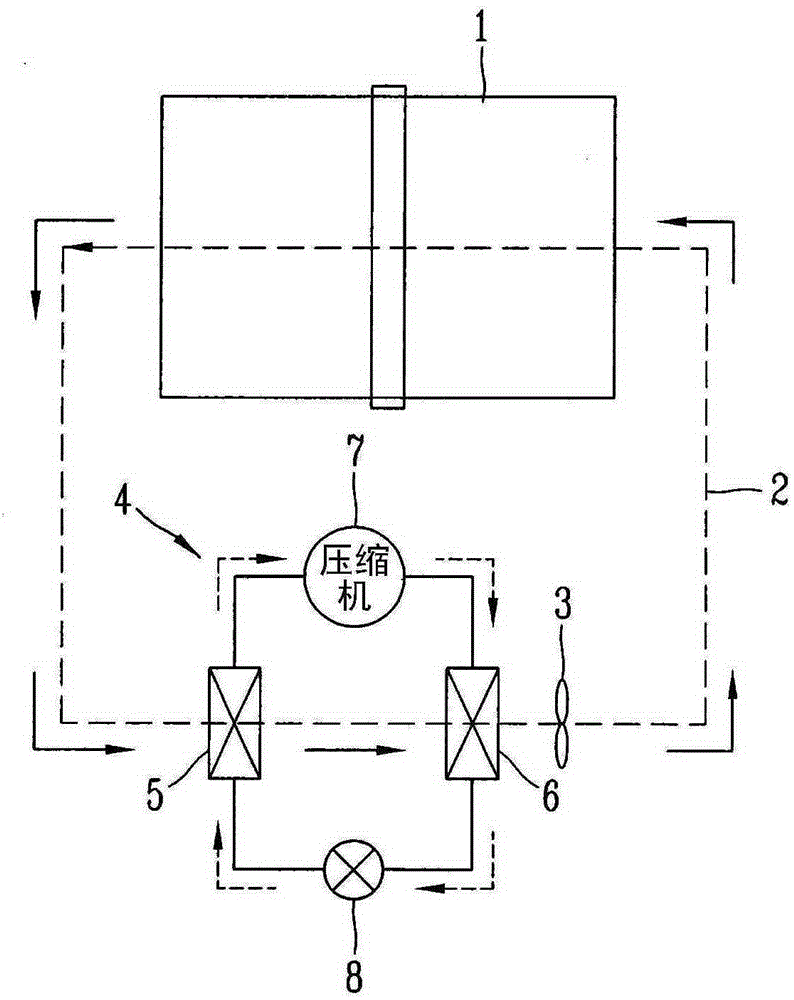

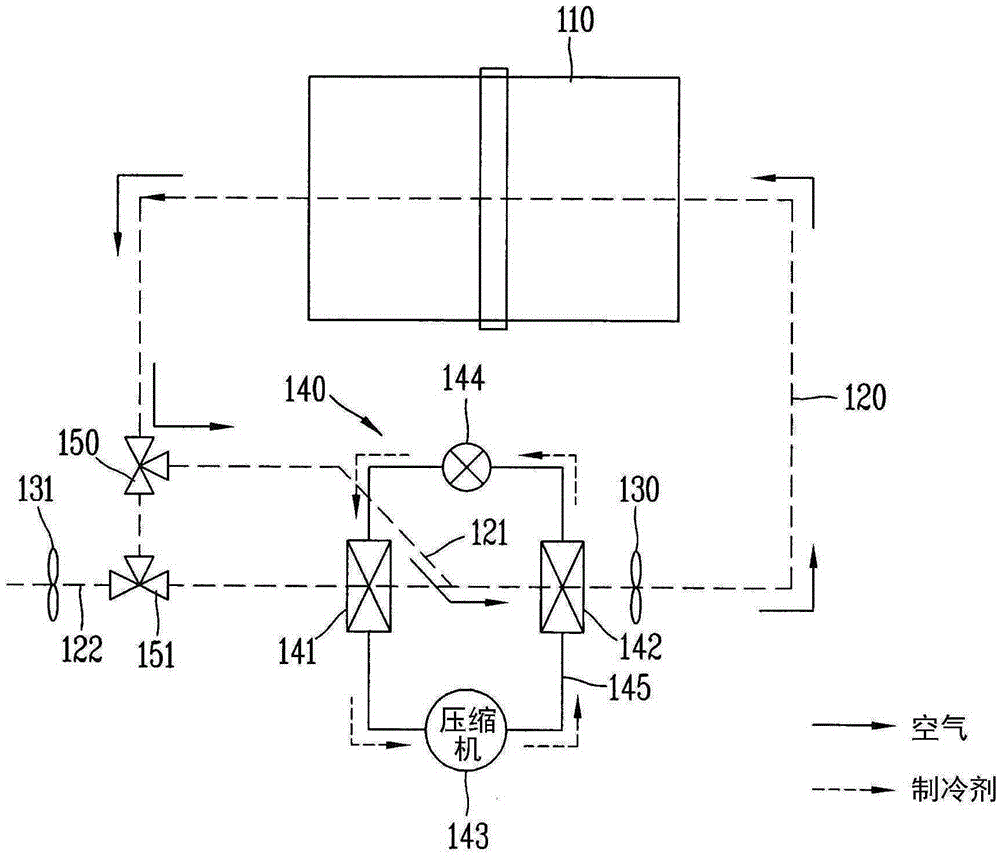

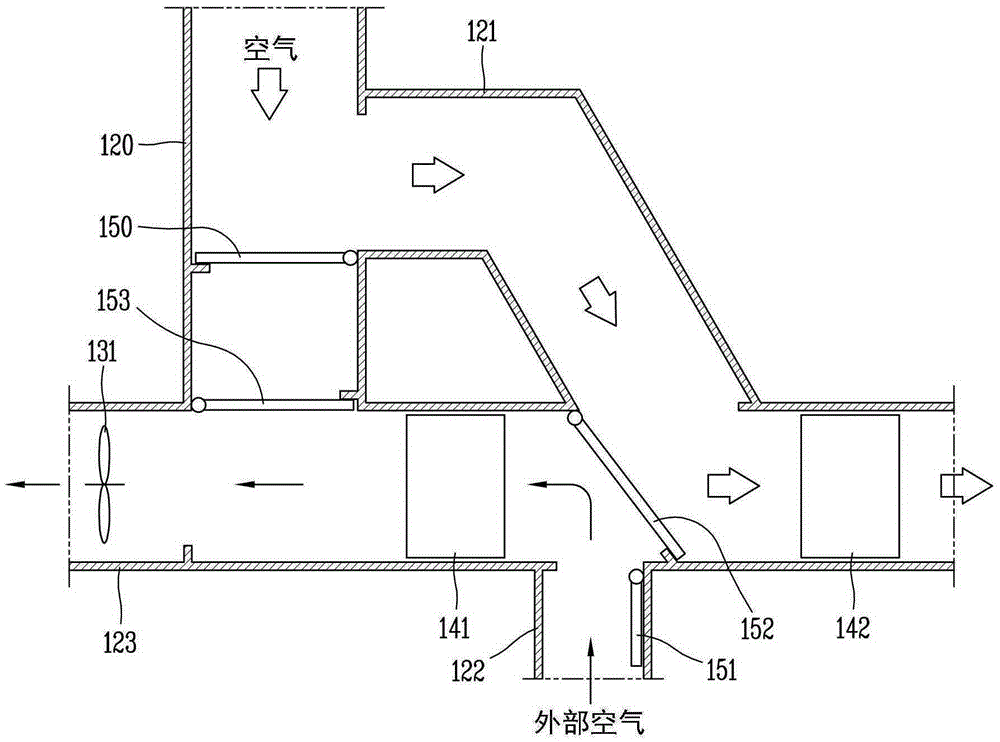

[0069] figure 2 is a schematic diagram of a laundry treatment device with a heat pump cycle 140 according to the first embodiment of the present invention.

[0070] The clothes processing device of the present invention includes: a housing, a drum 110, a circulating air duct 120, a circulating fan 130, a heat pump cycle 140 and a control unit 170 (refer to Figure 5 ).

[0071] The casing constitutes the appearance of the laundry processing device, and the upper end of the casing is provided with a user input unit, a display unit, etc. During laundry, the user can select a variety of functional modes through the user input unit, and can notify the user of the current status through the display unit .

[0072] Drum 110 accommodates laundry and dried laundry. The drum 110 may have a cylindrical shape with a receiving space for receiving objects. The drum 110 is rotatably disposed inside the casing. The front portion of the drum 110 is open, and the front portion of the hou...

no. 2 example

[0127] Figure 7 is a schematic diagram of a laundry treatment apparatus with a heat pump cycle 240 according to a second embodiment of the present invention.

[0128] Figure 7 The illustrated heat pump cycle 240 also includes a second evaporator 249 , a first three-way valve 246 and a second three-way valve 248 connected in parallel. In this embodiment, the control device of the laundry treatment device includes a control unit capable of communicating with various structures of the laundry treatment device. The control unit controls the action of each structural component by sending a control signal to each structural component of the laundry processing device. omit pairing and figure 2 Descriptions of structural components are repeated for illustrative purposes.

[0129] The first evaporator 241 is disposed inside the circulating air duct 220 , and the air flowing out from the drum 210 can pass through the first evaporator 241 .

[0130] In the figure, the second evap...

no. 3 example

[0138] Figure 8 is a schematic diagram of a laundry treatment apparatus with a heat pump cycle 340 according to a third embodiment of the present invention.

[0139] Figure 8 The illustrated heat pump cycle 340 also includes a second evaporator 349, a first three-way valve 346, a second three-way valve 348, and a second expansion valve 344b connected in series. In this embodiment, the control device of the laundry treatment device includes a control unit capable of communicating with various structures of the laundry treatment device. The control unit controls the action of each structural component by sending a control signal to each structural component of the laundry processing device. Omit here and figure 2 Descriptions of structural elements that are repeated for illustrative purposes.

[0140] The first evaporator 341 is disposed inside the circulating air duct 320 , and the air flowing out from the drum 310 can pass through the first evaporator 341 .

[0141] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com