Prefabricated steel-concrete composite beam construction

A steel-concrete composite beam and prefabricated assembly technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problem that the prefabricated steel-concrete composite beam structure cannot continue to bear external loads, the failure of the connection between the steel beam and the precast concrete bridge deck, Uneven distribution of stress and other problems, to achieve the effect of convenient construction, simple production, and improved shear bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

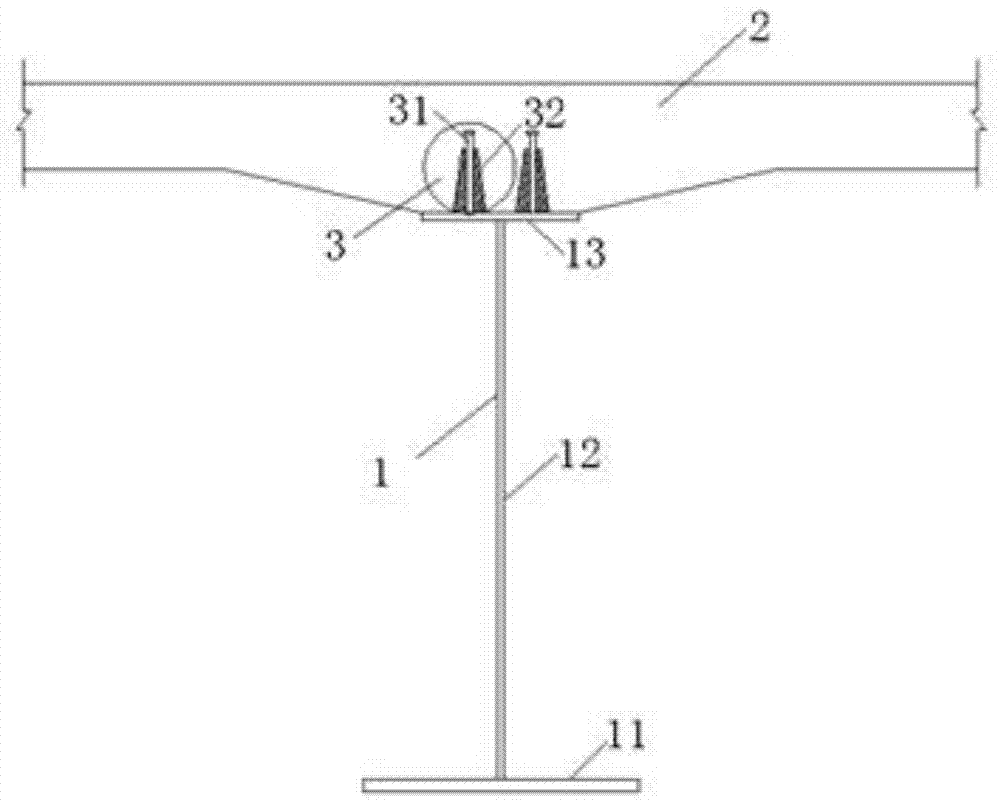

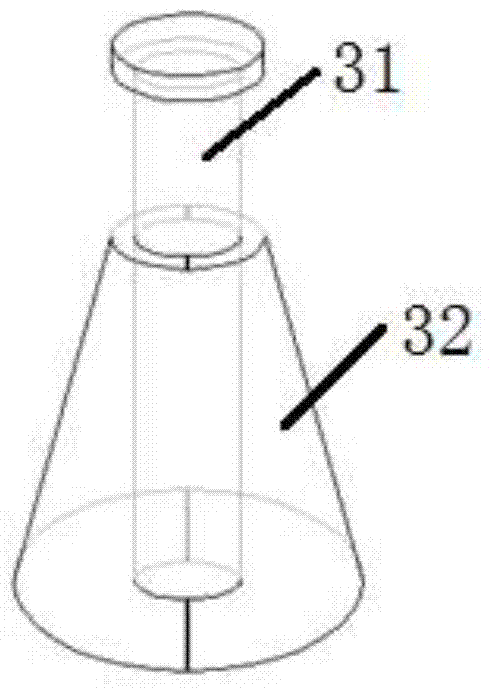

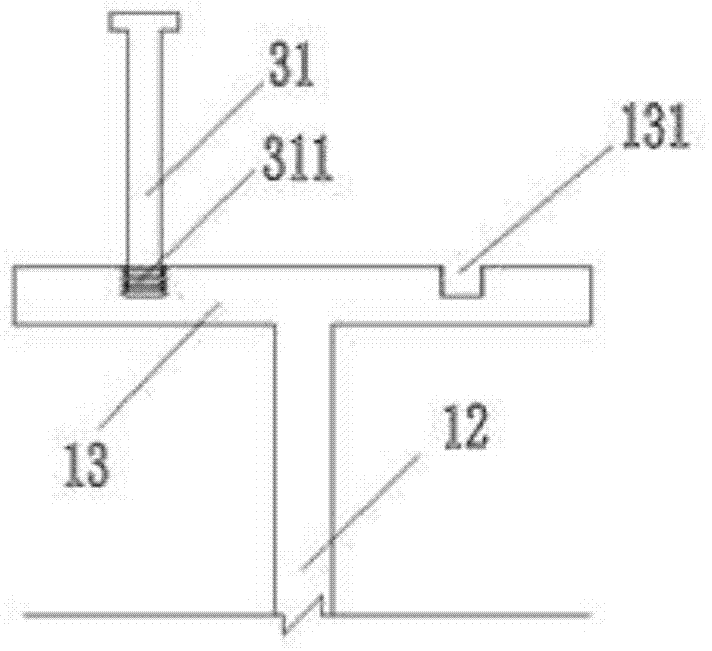

[0023] The three-dimensional view of the connection structure of the prefabricated steel-concrete composite beam proposed by the present invention is as follows figure 2 As shown, the cross-sectional view of the specific use process is as follows figure 1 As shown, the application process includes a steel girder 1 , a bottom plate 11 , a web 12 , a steel girder top plate 13 , a concrete bridge deck 2 , a connection structure 3 , bolt holes 131 , pegs 31 , sleeves 32 and threads 311 .

[0024] The steel beam 1 is an I-shaped steel beam, the bottom plate 11 and the steel beam top plate 13 are arranged parallel to each other, and the web 12 is vertically arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com