Construction method for erecting steel tube stiff bridge framework through asymmetric lifting

A construction method and asymmetrical technology, which can be applied in erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of difficult construction such as difficulties in erecting water platforms, and achieve the effects of saving temporary facilities workload, cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

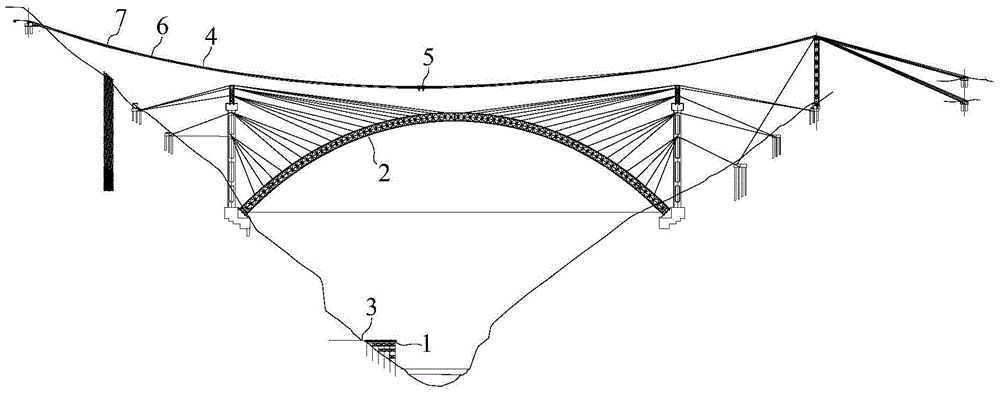

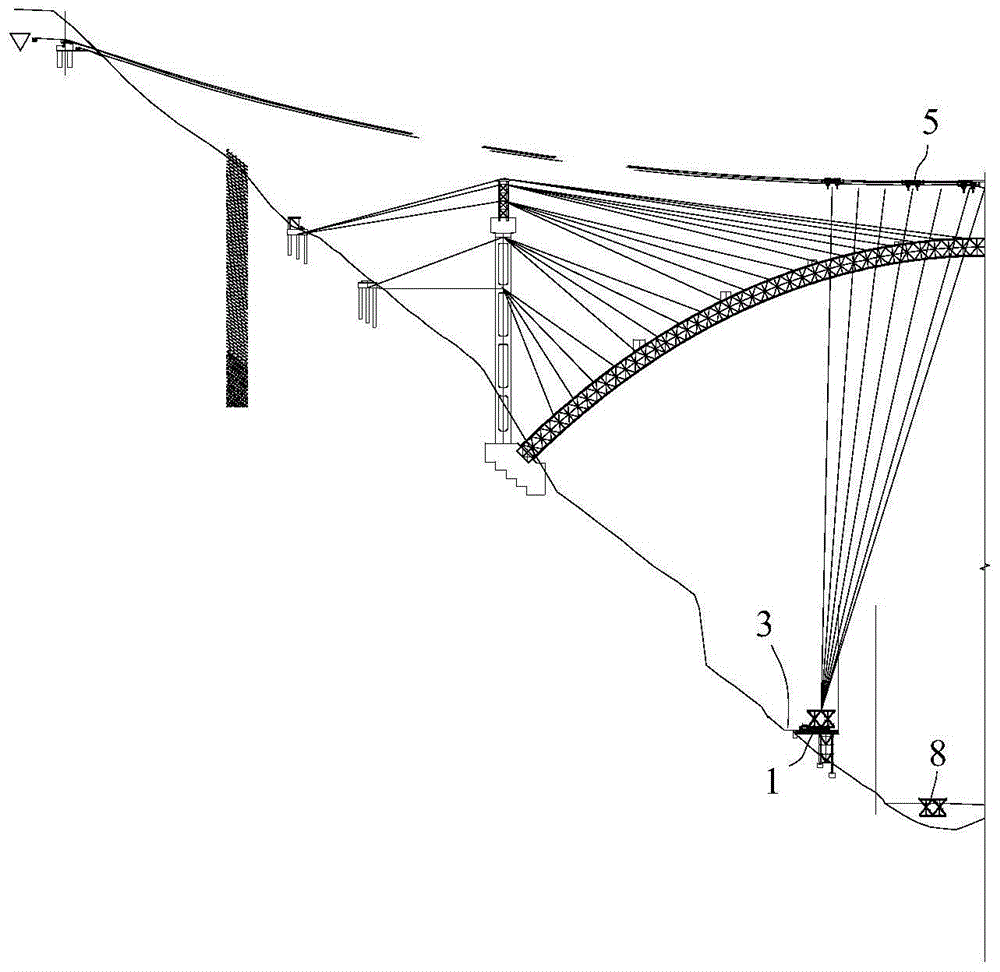

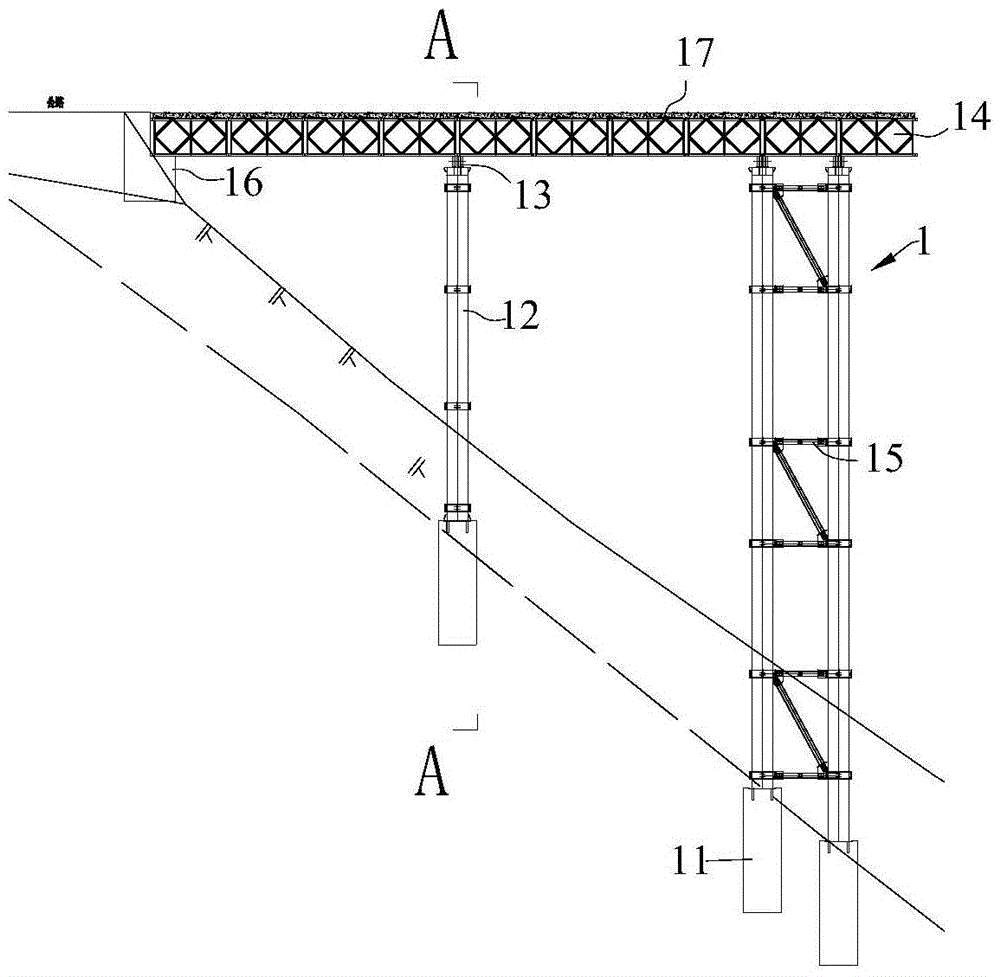

[0022] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0023] The purpose of the present invention is to plan ahead and change the water platform into a land platform when the terrain of the construction site is complex and it is not possible to erect a lifting platform at the mid-span position. According to the terrain conditions, a hoisting platform (the 13th section corresponding to the skeleton) was erected on the side slope of the east bank road and the valley, but the hoisting space was limited. When the east bank was erected to the 13th section, the remaining sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com