Hollow bridge pier capping construction method

A technology for hollow piers and bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inaccurate lifting and unloading positioning, inconvenient fixing, etc., and achieve strong manufacturability, easy fixing and installation, and easy fixed installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

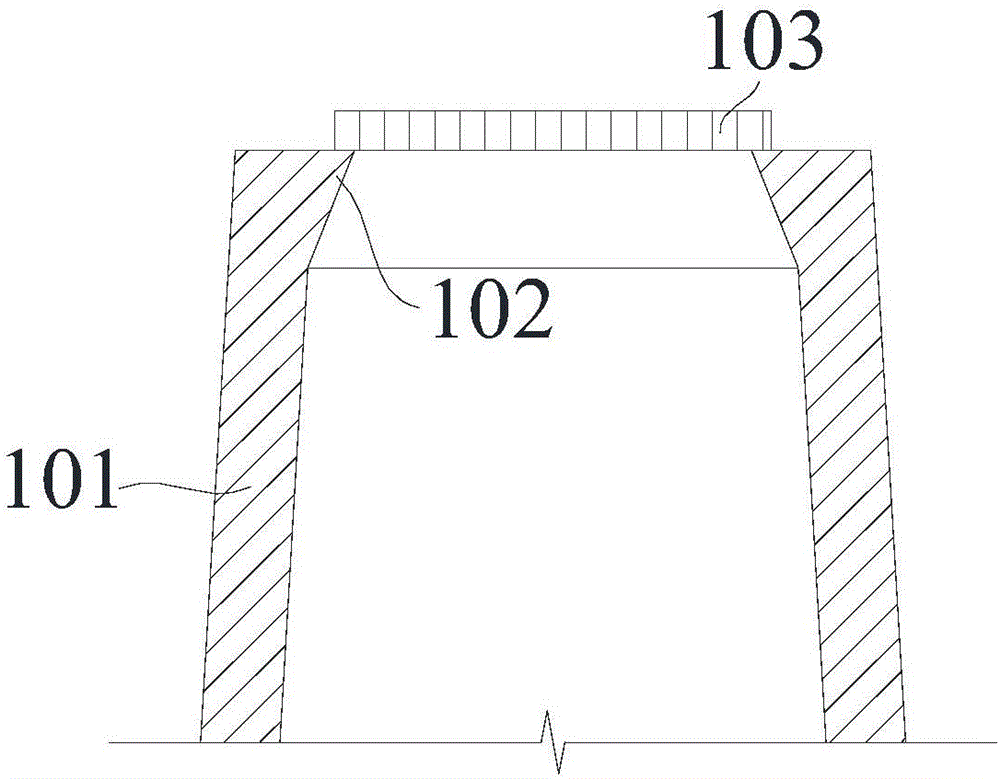

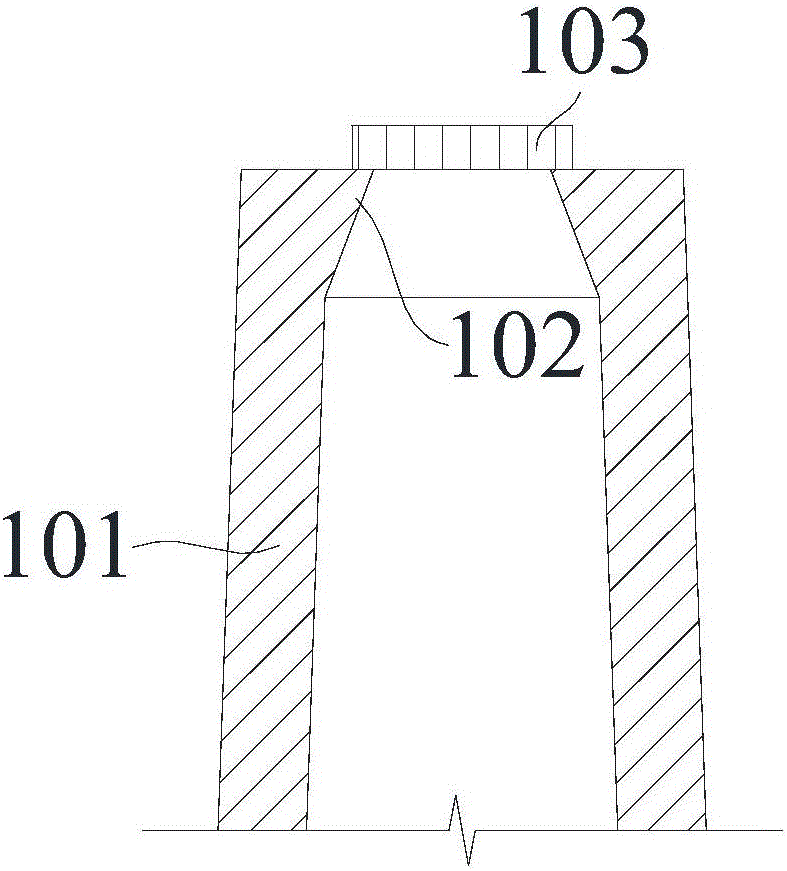

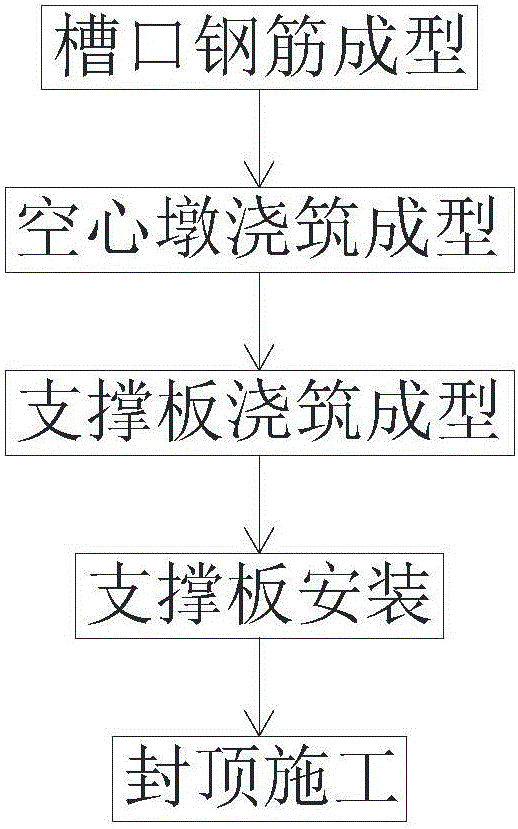

[0041] Such as Figure 3-6 As shown, a schematic flow chart of a bridge hollow pier capping construction method according to the present invention and a bridge pier built by the method, including a pier wall 1, an upper chamfer 11, a support end 12 and a support plate 2, and the specific implementation steps are as follows: :

[0042] a, the notch reinforcing bar forming, after the pier wall 1 reinforcing bar of the hollow pier is bound and formed, a circle of notch reinforcing bar is bound on the end of the upper chamfer 11 reinforcing bar provided with on the inner cavity side wall of the pier wall 1, forming a section of The shape of the L-shaped notch does not change the original design of the upper chamfer 11, ensuring that the original design opening size remains unchanged and optimizes the mechanical properties of the structure;

[0043] b. Hollow piers are poured into shape, concrete is poured on the steel bars of the pier wall 1 to form the hollow pier, the upper cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com