H-shaped steel foundation pit support device with grouting small conduit resisting soil lateral pressure

A technology of grouting small conduits and foundation pit support, which is applied in foundation structure engineering, excavation, construction, etc., and can solve the problems of short construction period, high cost of cast-in-situ piles, and non-reusable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described below in conjunction with accompanying drawing

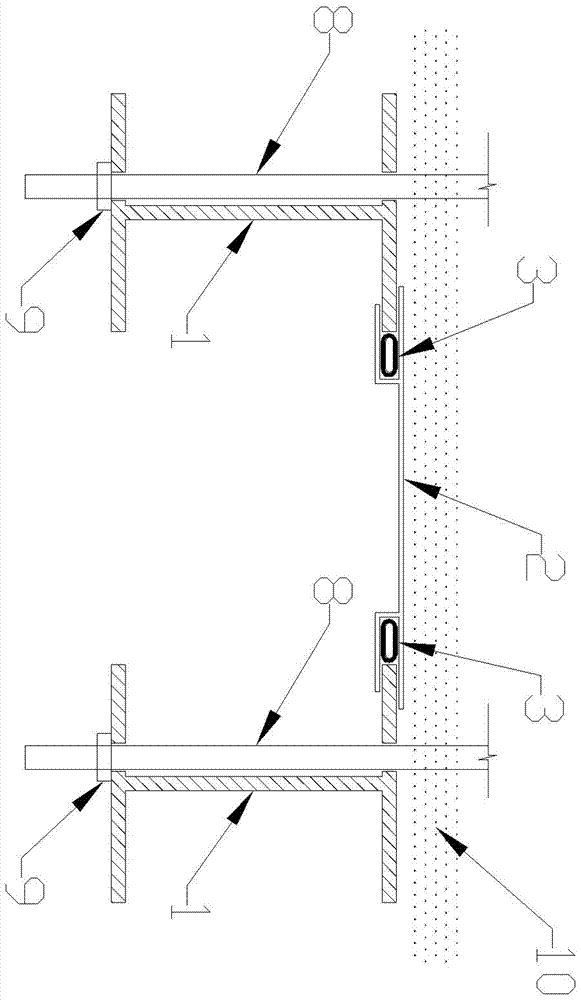

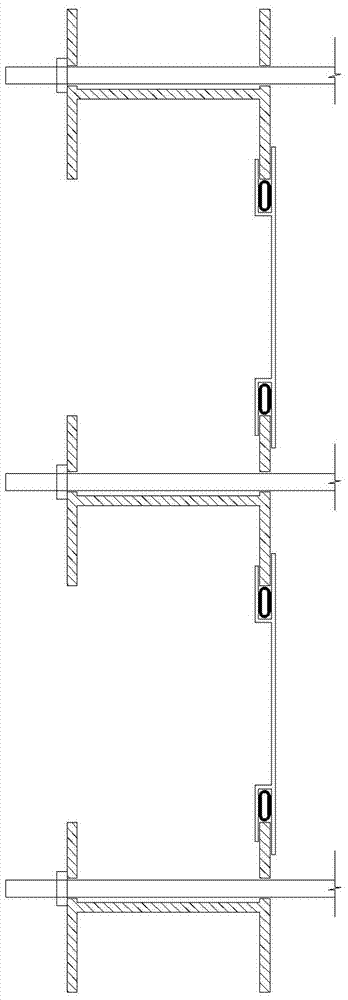

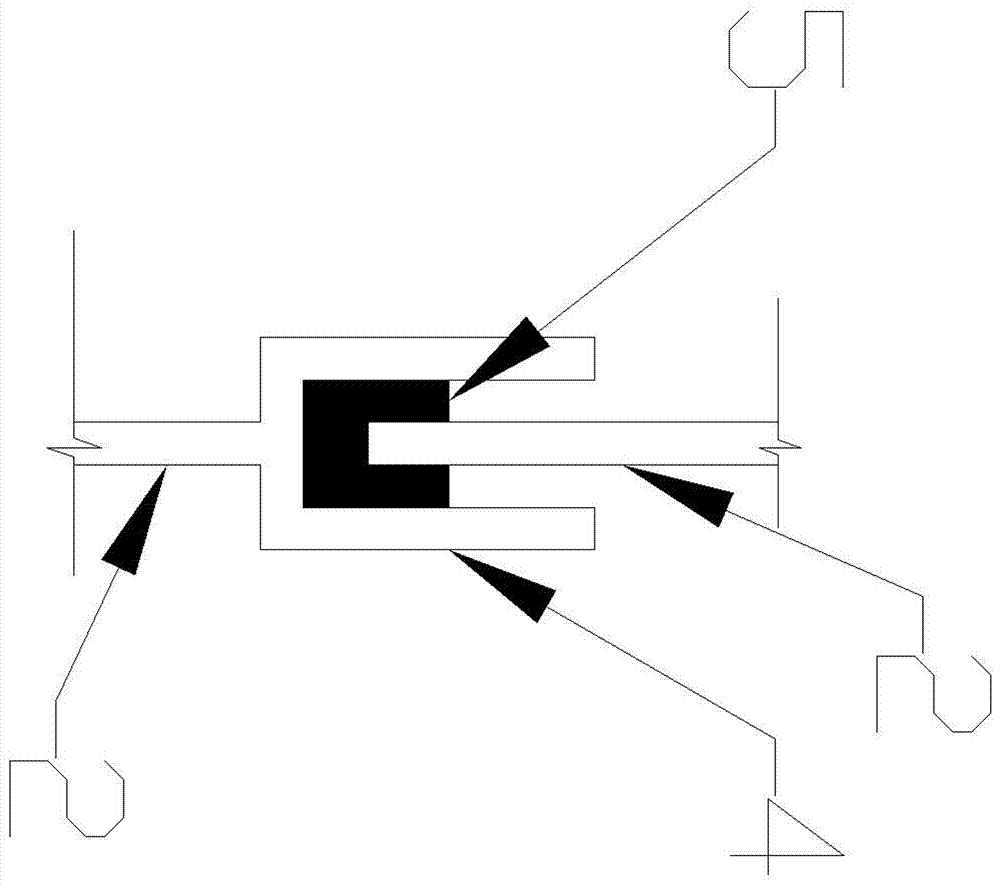

[0012] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 First, drive or press the pile 1 of the present invention to the design elevation one by one on the flat site according to the design sideline of the deep foundation pit drawing. Install the water-stop air bag 3 in the water-stop groove 6 of the segmental steel sheet pile 2 and install the water-stop strip 5 in the "U"-shaped groove 4, and then insert the water-stop groove 6 at both ends of the segmental steel sheet pile 2 into the flange of the adjacent pile 1 On the board, use special pile pressing equipment to press the segmented steel sheet pile 2 into the soil layer of the first construction section, the support system of the first unit is completed, and the support system of the other units is completed in the same way, so that the support system of the second unit is completed. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com