Quickly-disassembled rotary opening cover lock

A flap lock and lock seat technology, which is used in construction locks, ship hatches/hatch, ship parts, etc., can solve the problem of unsteady opening and closing of flap locks, unfavorable installation of small flaps, and damage to the structural strength of flaps, etc. problem, to achieve the effect of convenient operation, reliable locking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below.

[0016] The technical problem to be solved by the present invention is: most of the current flap locks are large in size, which is not conducive to installation on small flaps. At the same time, they need to be installed on the large opening of the flap, which damages the structural strength of the flap. At the same time, the opening and closing of the lid lock is jerky and laborious, which is not easy to operate.

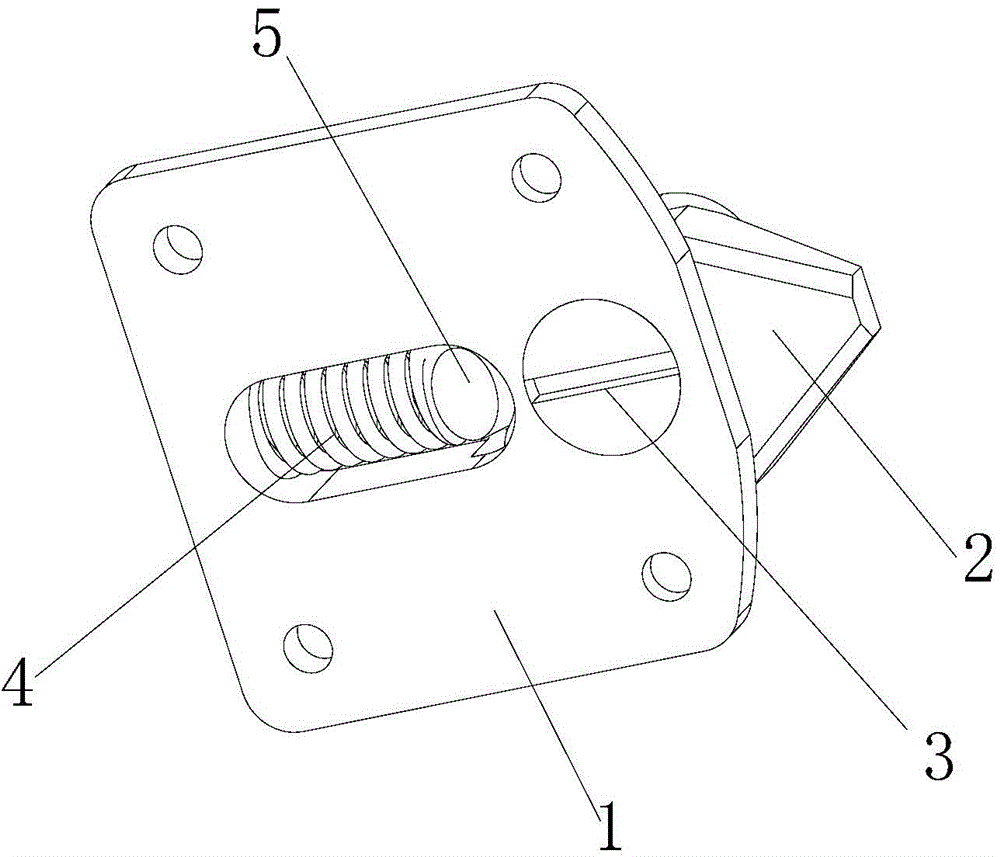

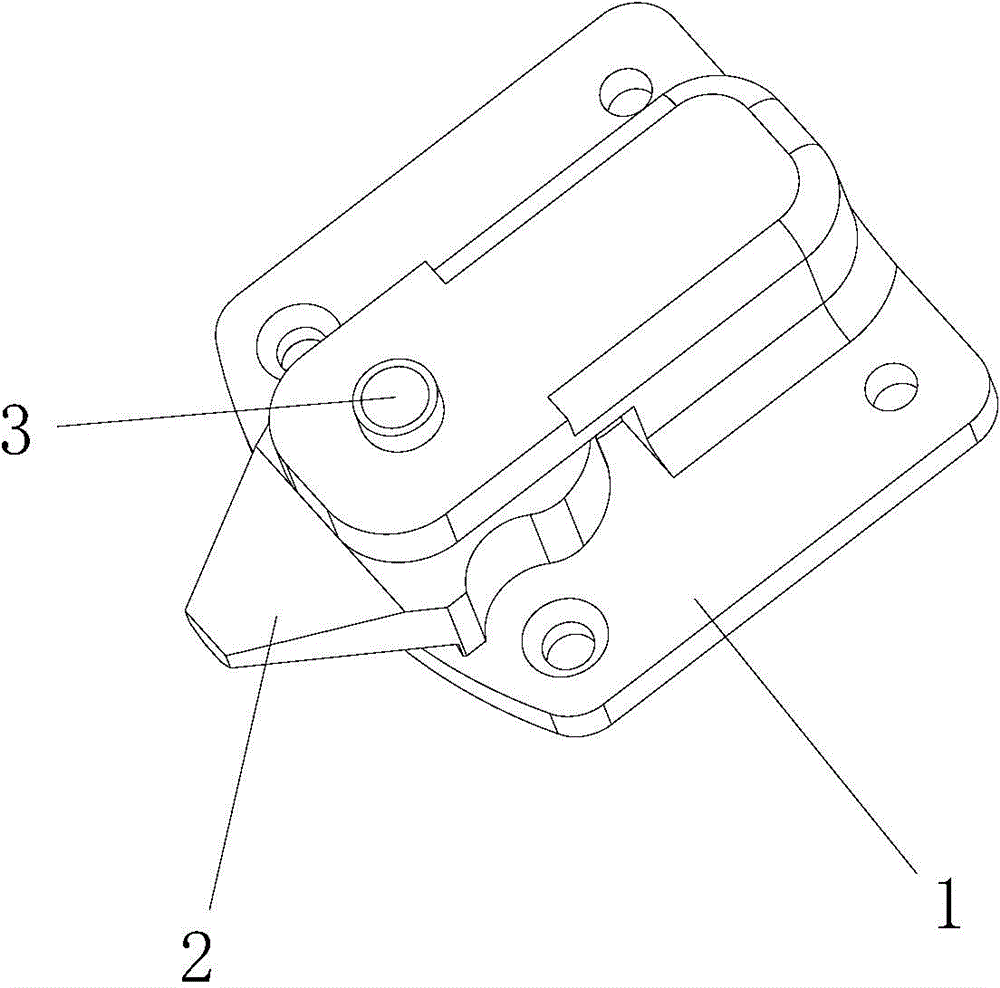

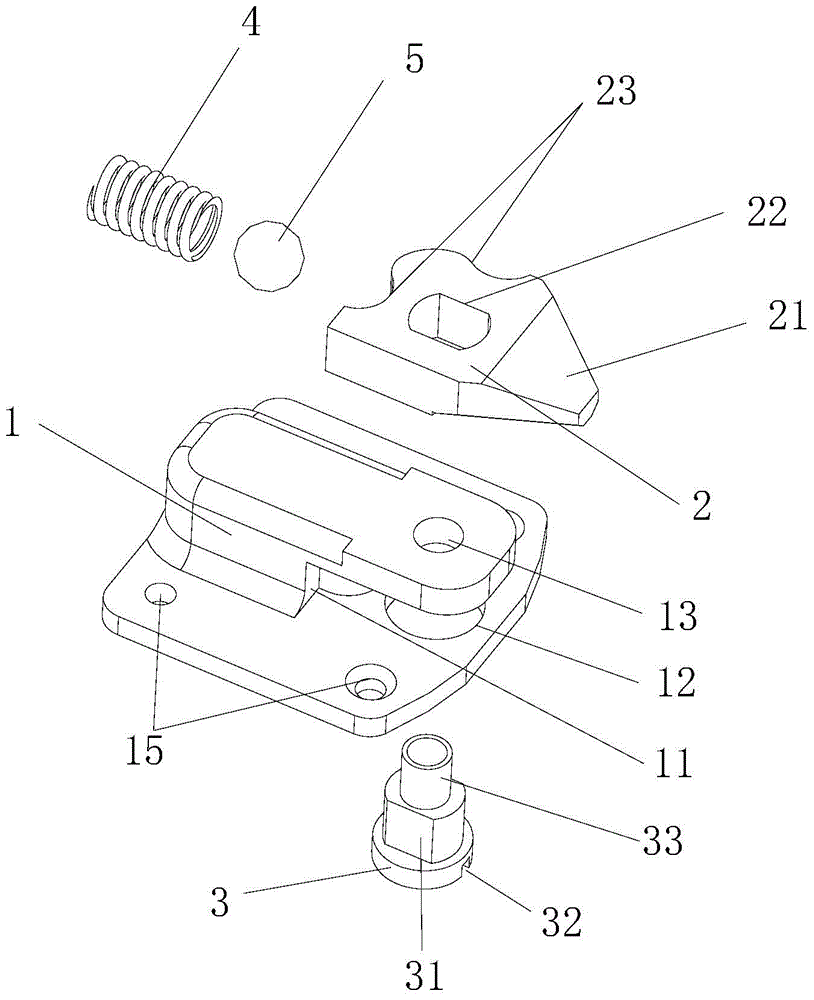

[0017] Please also see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . The quick-release rotary flap lock of the present invention comprises: a lock base 1, a lock tongue 2, a special-shaped pin 3, a spring 4 and a steel ball 5;

[0018] The upper part of the lock base 1 is a rectangular parallelepiped with a notch 11 at the lower part of one end, and the lower part of the lock base 1 is a square plate structure; the upper part of the lock base 1 facing the gap 11 has a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com