A double-acting multi-stage anti-rotation hydraulic cylinder

A double-acting, hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of high production cost, large processing difficulty, large space occupation, etc., and achieves the effects of easy processing, low cost, and satisfying use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

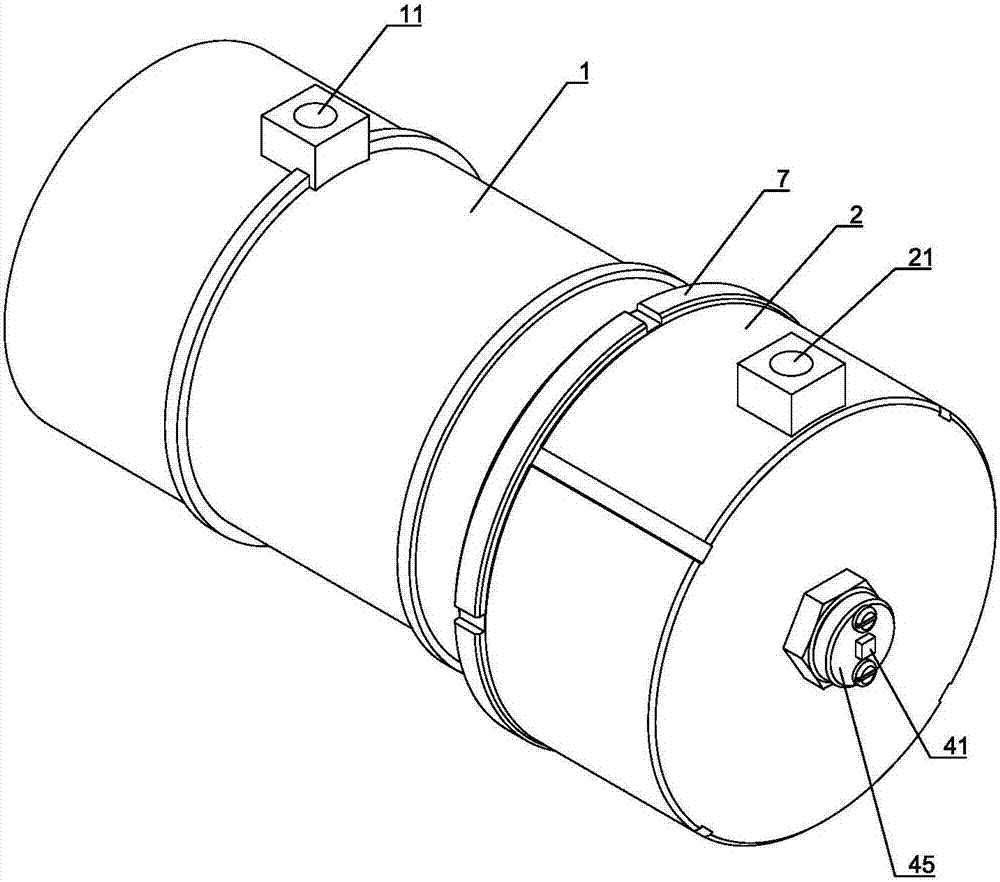

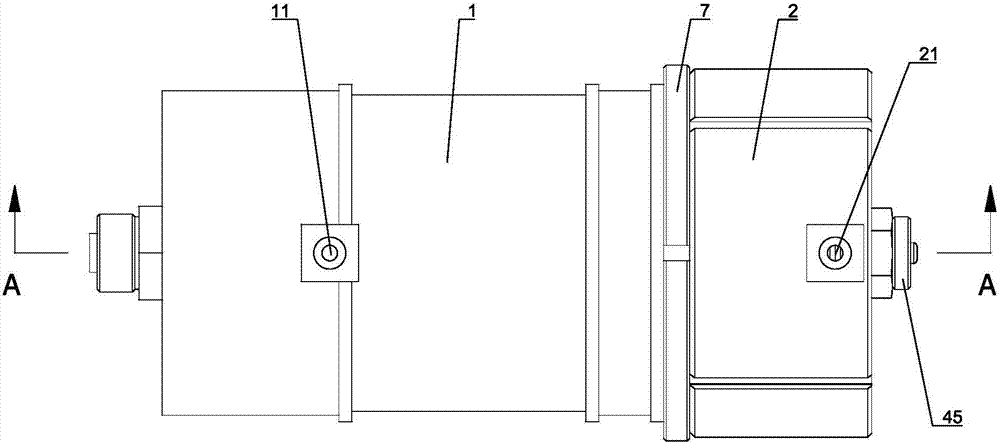

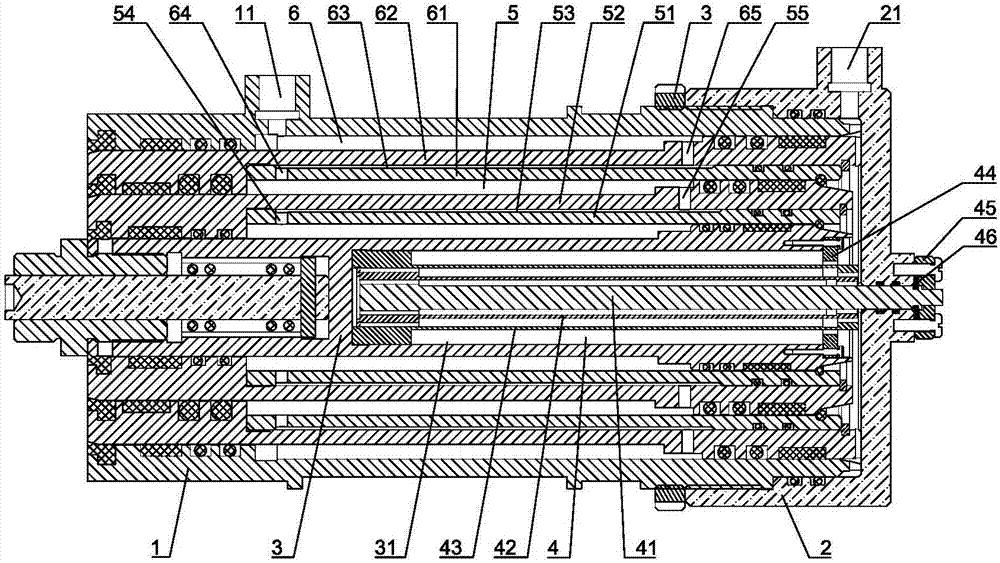

[0065] Such as Figure 1 to Figure 44 Shown is a specific embodiment of a double-acting multi-stage anti-rotation hydraulic cylinder of the present invention, which generally includes a housing 1 , a rear end cover 2 and a piston rod 3 . A cylinder is sheathed on the outer circumference of the piston rod 3, and the piston rod 3 and the cylinder are coaxially installed in the inner cavity of the housing 1, and the rear end cover 2 is fixedly installed on the rear end of the housing 1. The positive cavity oil port 21 is set on the rear end cover 2, and the positive cavity oil port 21 is always connected with the positive cavity oil chamber of the piston rod 3 and the cylinder barrel, and the reverse cavity oil port 11 is set on the shell 1, and the reverse cavity The oil port 11 is always in communication with the anti-cavity oil chamber of the piston rod 3 and the cylinder barrel. At the same time, the piston rod anti-rotation assembly 4 of the telescopic rod structure is set,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com