Micro-flow labyrinth bypassing pressure adjusting and stabilizing valve

A micro-flow, pressure-stabilizing valve technology, applied in the valve's device for absorbing fluid energy, sliding valve, valve details, etc., can solve the problems of low safety and reliability, large maintenance workload, complex system structure, etc. The effect of technical level, less maintenance workload, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

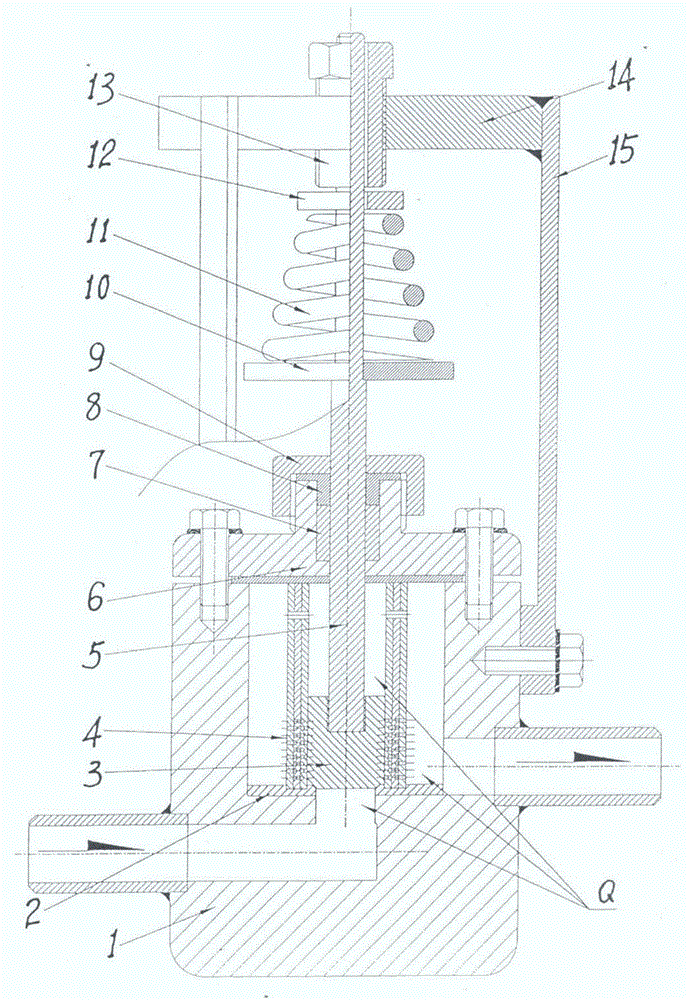

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

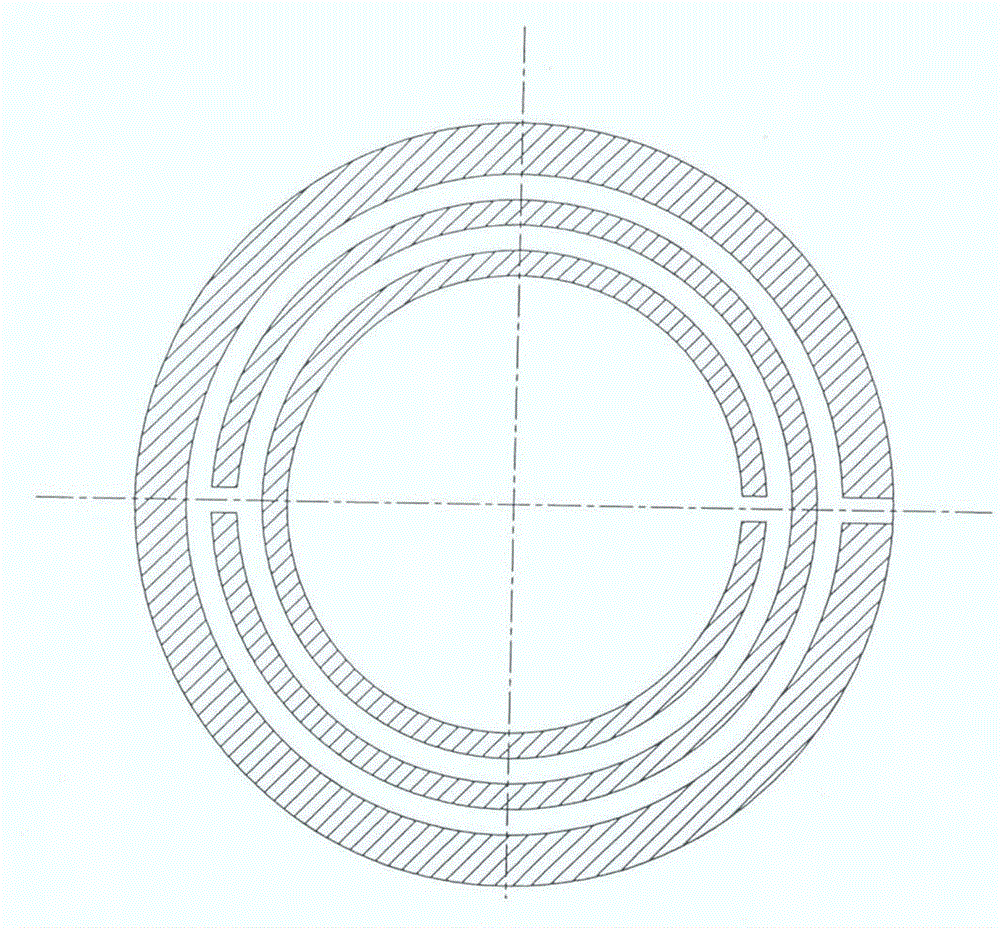

[0025] A micro-flow labyrinth bypass type pressure regulating and stabilizing valve, which consists of a valve body 1, a valve core seat 2, a valve core 3, a bypass labyrinth body 4, a valve stem 5, a valve cover 6, a packing 7, a pressure ring 8, a pressure Cap 9, balance plate 10, spring 11, limit ring 12, trimming knob 13, top plate 14, support 15 constitute;

[0026]The micro-flow labyrinth bypass pressure regulating and stabilizing valve, the bottom end of the chamber of the valve body 1 is inlaid with the valve core seat 2, and the upper end of the valve body 1 is connected to the valve cover 6, the valve core seat 2 and the bypass labyrinth body 4 The bottom ends are all fixedly connected, and the bottom surface of the bonnet 6 is connected with the upper end of the flow-around labyrinth body 4 by pressing against each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com