Method for processing waste lye generated in olefin separating unit alkali washing system

A technology for separation and treatment of olefins, which is applied in the field of separation of mixed olefins in the coal chemical industry. It can solve problems such as failure to deliver normally, blockage of lye delivery pipelines, and nozzles of incinerators, etc., to ensure long-term operation, shorten residence time, and solve blockages. Effects of transfer pumps and lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

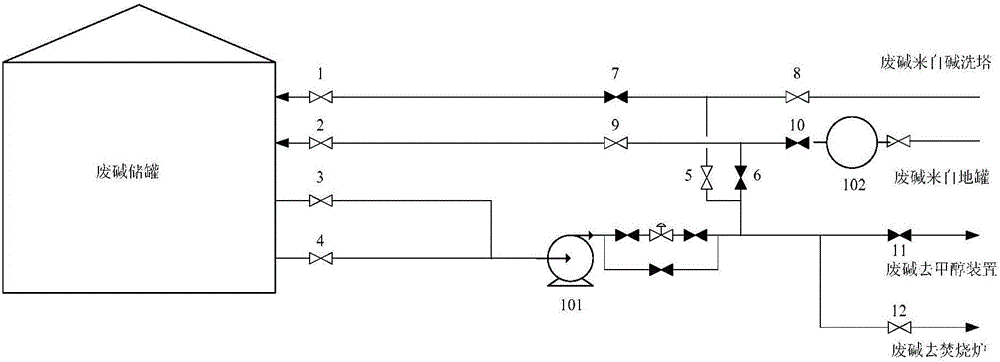

Image

Examples

Embodiment 1

[0024] According to the liquid level / interface calculation formula Control the boundary position of the alkali washing tower kettle and the butter side liquid level in the alkali washing system of the olefin separation unit, where F is the buoyancy of the medium, D is the diameter of the inner cylinder, and H is the length of the inner cylinder; ρ is the density of the medium or the density difference between the two media, When ρ is the density of butter, the liquid level on the butter side is calculated, and when ρ is the density difference between the spent lye and butter, the boundary position of the cauldron of the alkali washing tower is calculated.

[0025] After a large number of sampling measurements and statistics, the technicians determined the density of waste lye at 1148kg / m 3 . The density of butter in the design is based on the density of butter in the traditional ethylene industry. In the coal chemical plant, due to the high content of oxides in the product g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com