Water-cooling type slag conveyer

A slag conveyor and water-cooled technology, which is applied in the field of high-efficiency and energy-saving pulverized coal boiler slag transportation, can solve the problems of high labor intensity and labor consumption, and achieve the effects of convenient operation, low running speed and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

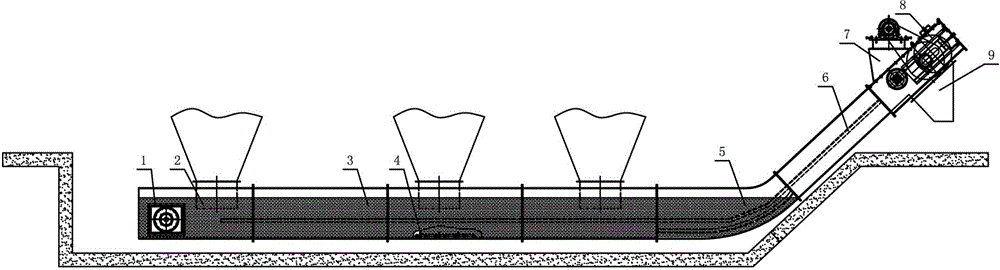

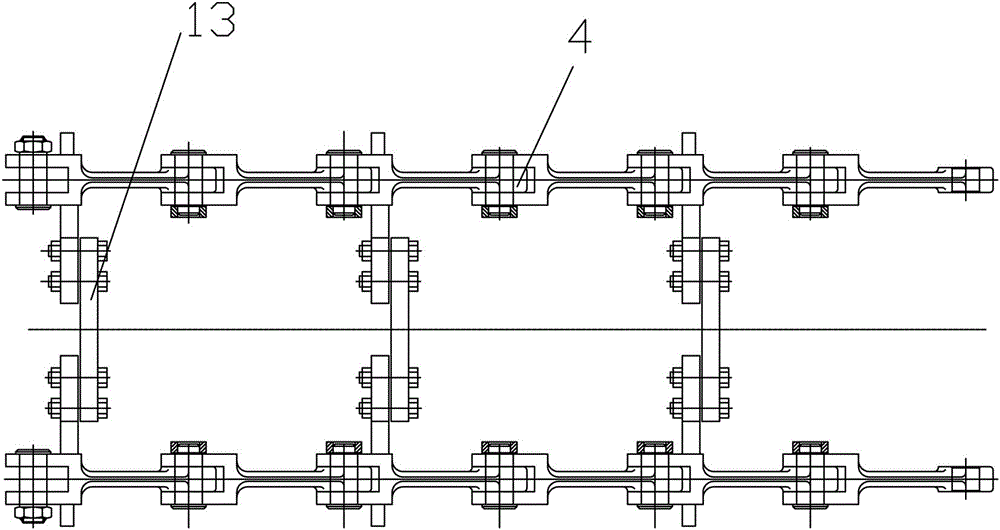

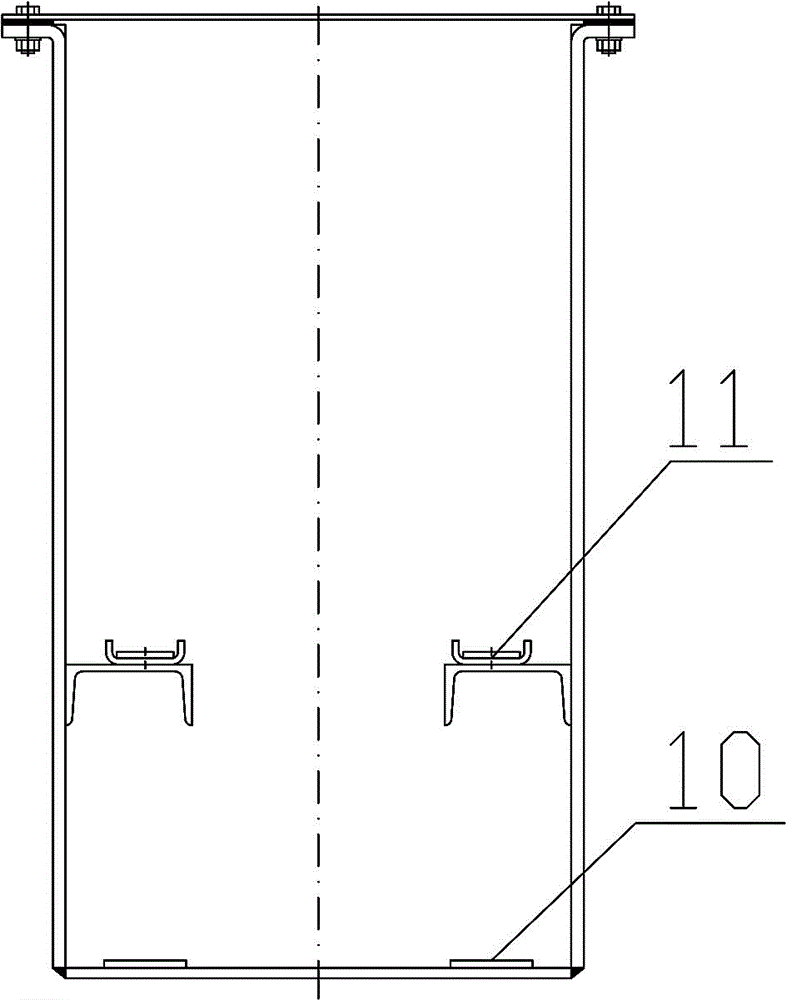

[0016] see Figure 1-4 , a water-cooled slag conveyor, which includes a casing with a closed cavity. The casing has a straight section, a curved section 5, and a transition section 6 in sequence. The conveying device is similar to the casing, and the conveying device sequentially includes a tail assembly 1, a scraper chain 4, a driving device 7, a head assembly 8 and a slag outlet 9, and the scraper chain is a double-row die-forging chain. Drive the slag to run from bottom to top, there is a scraper between the double-row die forging chains, a wear-resistant guide rail 10 is provided at the bottom of the casing, and a U-shaped chute 11 is provided on both sides of the casing above the wear-resistant guide rail. Mill rails and U-shaped chutes are used to support and guide the scraper chain.

[0017] The casing of the water-cooled slag conveyor is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com