A heat recovery device structure and air-cooled heat pump unit

A heat recovery device and water heat exchanger technology, applied in the field of heat pumps, can solve problems such as low pressure protection, insufficient liquid supply of electronic expansion valves, refrigerant heat recovery devices cannot be taken away, etc., to achieve reliable operation, high work efficiency, and improved reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

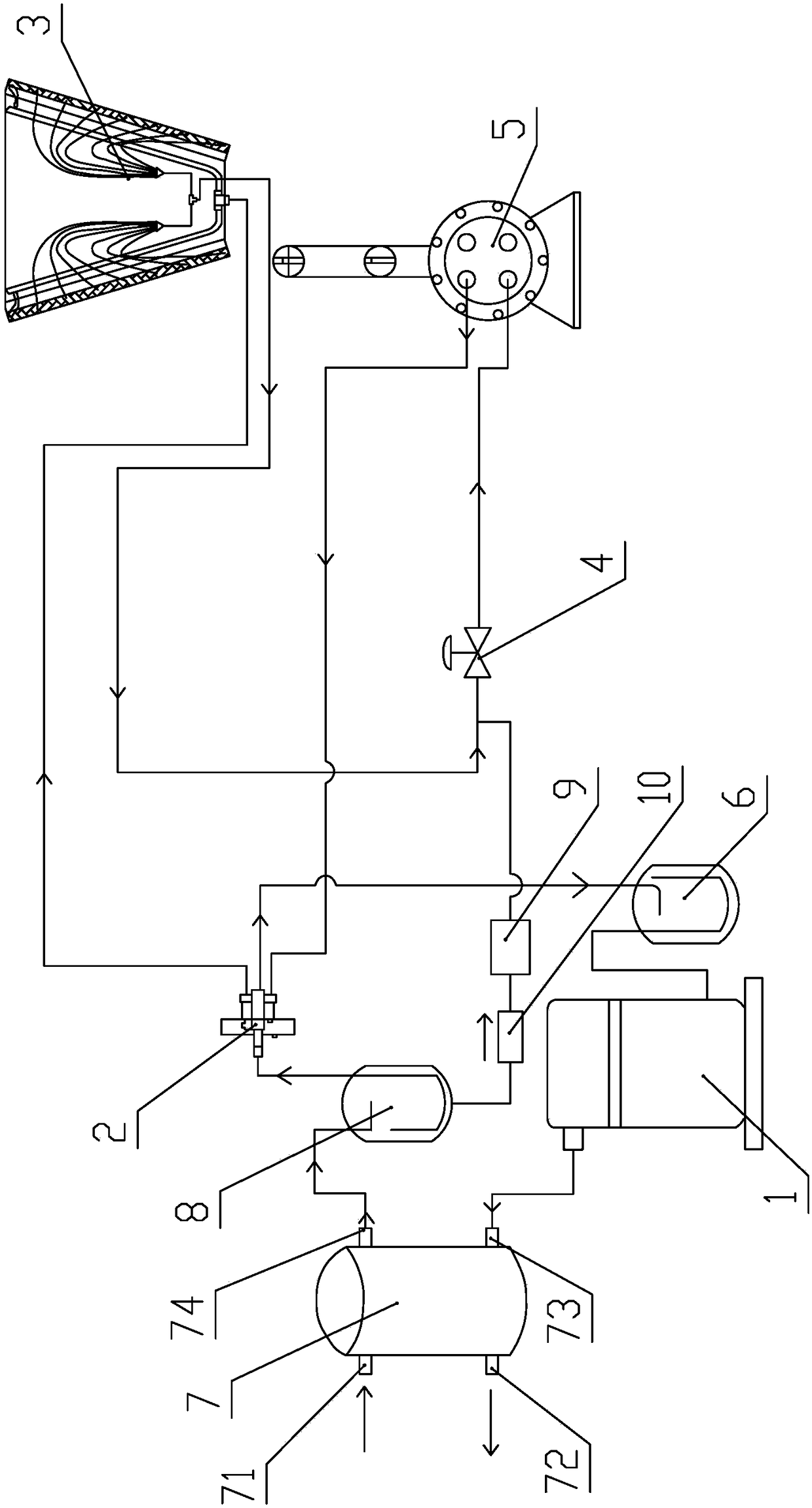

[0026] This embodiment provides a heat recovery device structure, such as figure 1 As shown, the heat pump system includes a compressor 1 , a four-way valve 2 , a condenser 3 , an electronic expansion valve 4 , an evaporator 5 and a first gas-liquid separator 6 , which are connected in sequence through pipelines. In this embodiment, the condenser 3 adopts a fin heat exchanger, and the evaporator 5 adopts a dry evaporator.

[0027] A water heat exchanger 7 is provided between the compressor 1 and the four-way valve 2. The water heat exchanger 7 has a water inlet 71, a water outlet 72, a refrigerant inlet 73 and a refrigerant outlet 74. The refrigerant inlet 73 of the water heat exchanger 7 It is connected to the compressor 1, and the refrigerant outlet 74 is connected to the four-way valve 2, so that the high-temperature and high-pressure gaseous refrigerant compressed by the compressor 1 first enters the water heat exchanger 7 for heat exchange with water, and then enters the ...

Embodiment 2

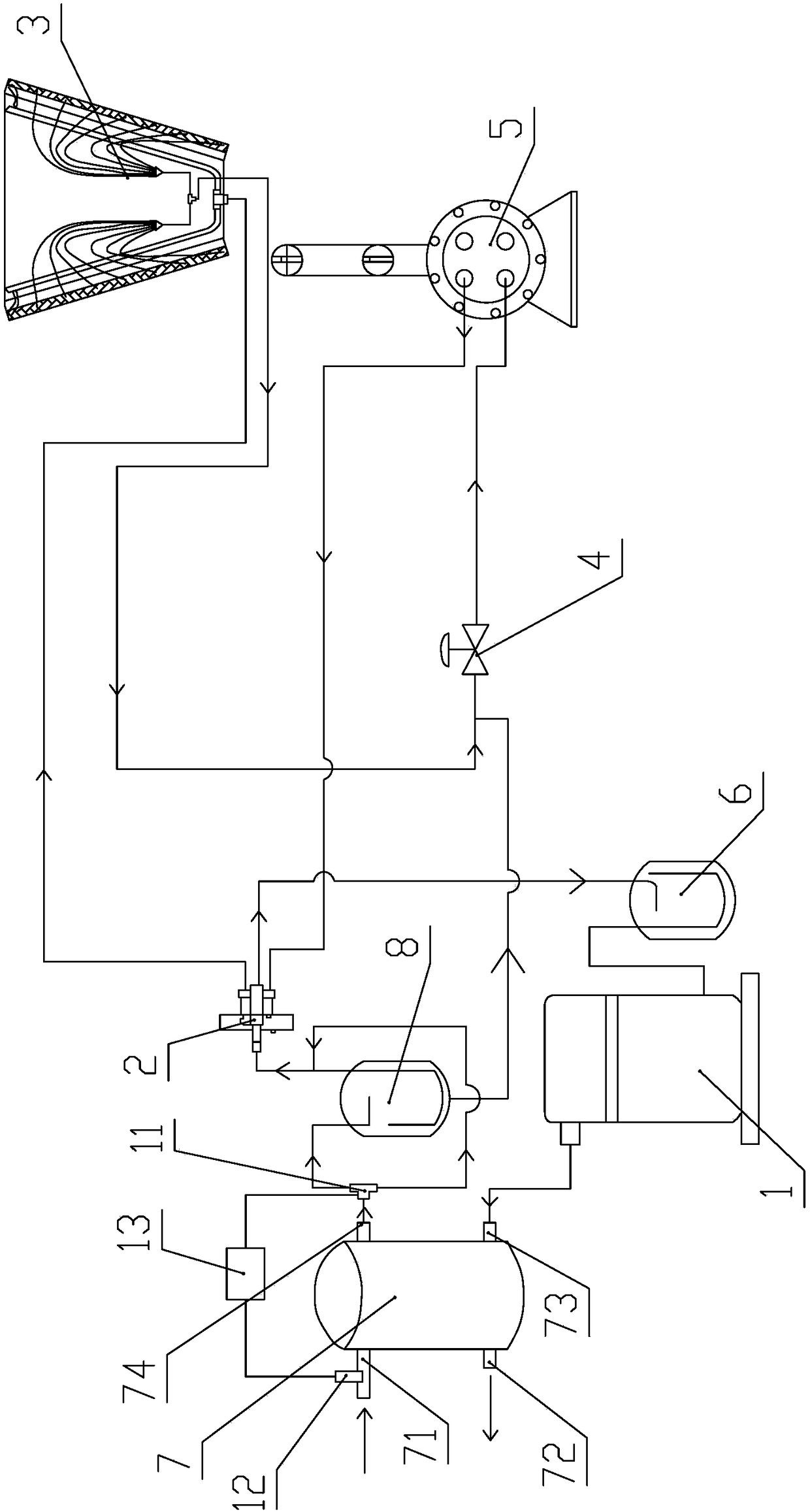

[0034] This embodiment provides a heat recovery device structure, such as figure 2 As shown in the figure, its structure is basically the same as that of the first embodiment, and its heat pump system includes a compressor 1, a four-way valve 2, a condenser 3, an electronic expansion valve 4, an evaporator 5 and a first gas-liquid separator 6 connected by pipelines in sequence. A water heat exchanger 7 is arranged between the compressor 1 and the four-way valve 2 , and a second gas-liquid separator 8 is also arranged between the water heat exchanger 7 and the four-way valve 2 .

[0035] The difference is that in this embodiment, a reversing valve 11 is provided between the water heat exchanger 7 and the second gas-liquid separator 8, and the inlet of the reversing valve 11 is connected to the refrigerant outlet 74 of the water heat exchanger 7, and the The first outlet of the valve 11 is connected to the inlet of the second gas-liquid separator 8 , and the second outlet is di...

Embodiment 3

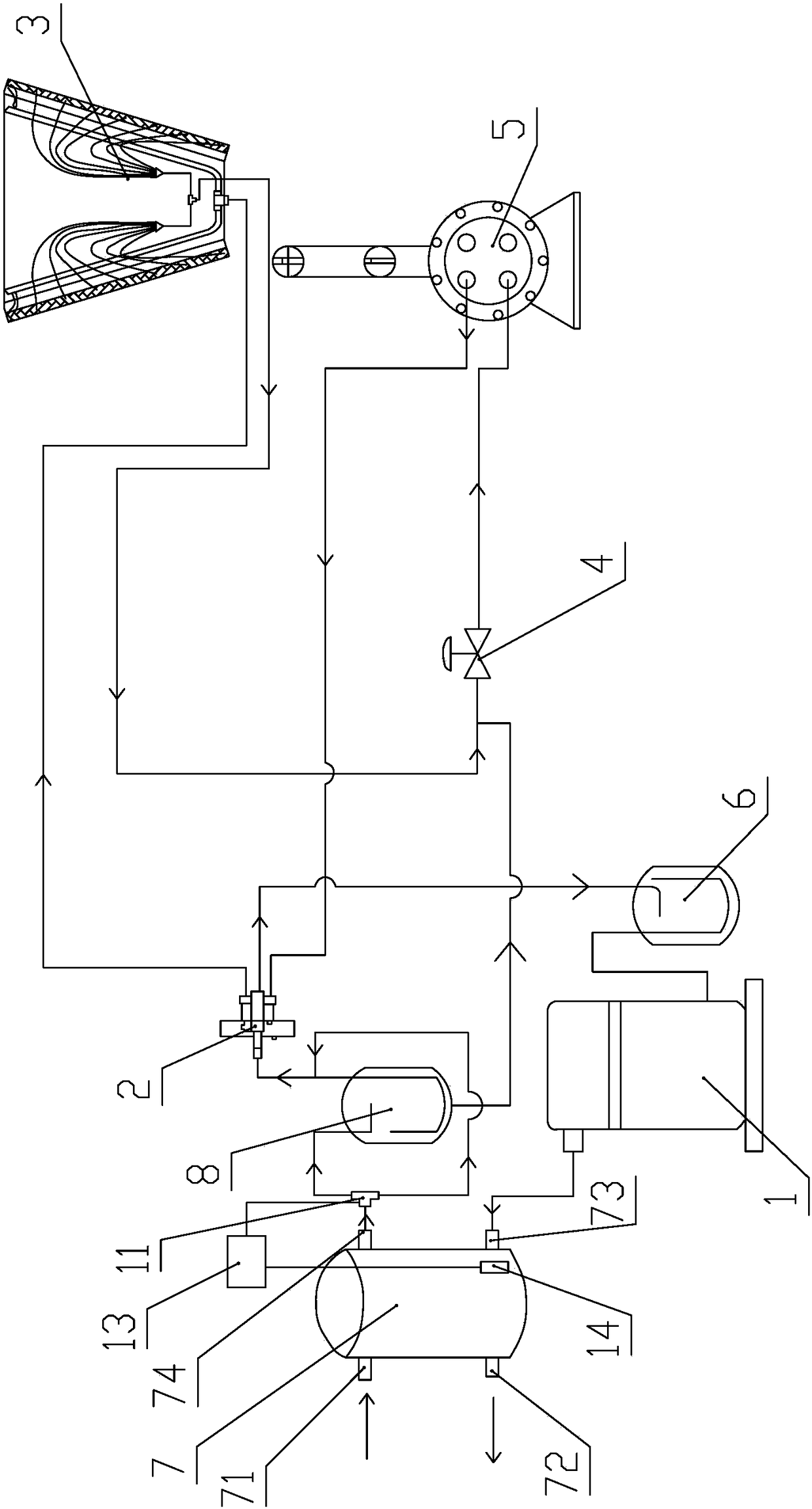

[0039] This embodiment provides a heat recovery device structure, such as image 3 As shown in the figure, its structure is basically the same as that of the first embodiment, and its heat pump system includes a compressor 1, a four-way valve 2, a condenser 3, an electronic expansion valve 4, an evaporator 5 and a first gas-liquid separator 6 connected by pipelines in sequence. A water heat exchanger 7 is arranged between the compressor 1 and the four-way valve 2 , and a second gas-liquid separator 8 is also arranged between the water heat exchanger 7 and the four-way valve 2 .

[0040] The difference is that in this embodiment, a reversing valve 11 is provided between the water heat exchanger 7 and the second gas-liquid separator 8, and the inlet of the reversing valve 11 is connected to the refrigerant outlet 74 of the water heat exchanger 7, and the The first outlet of the valve 11 is connected to the inlet of the second gas-liquid separator 8, the second outlet is directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com